Hello from the middle of the world,

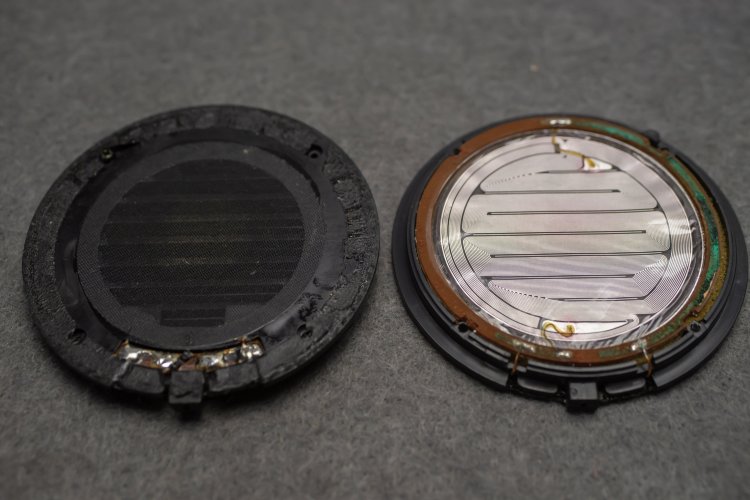

I'm looking for some help with the drivers on my Dual DK830's. They were working / sounding great as ever until I felt a rattle and decided to take them apart and found that the foam spacers / dampers had become dry and caked, with some of the holes on the rear side of the drivers completely covered in gunk.

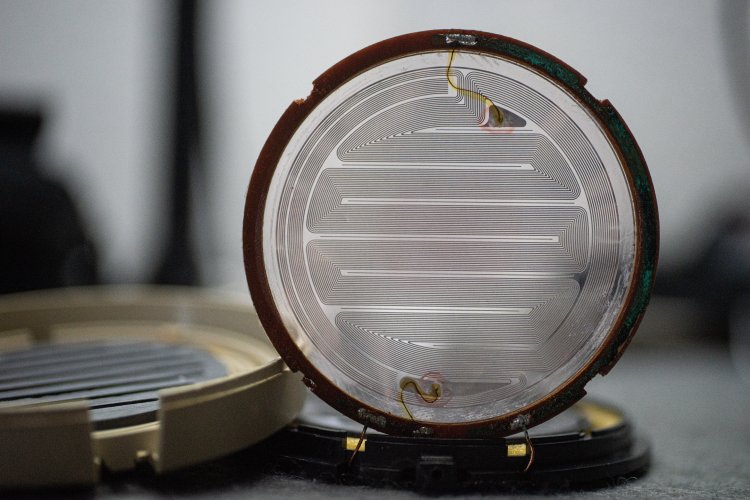

So then, being my OCD self, I decided to go ahead and clean them with a toothbrush, Fantastik (mild household degreaser) and water. When I put them back together, to m surprise one side was gone, dead, NADA. I un-soldered the wires and sure enough, when I used my multimeter I saw there was no conductivity between the one terminal and the other. SO I proceeded to remove the clamps and see if there was any conductivity within the membrane itself and THAT is apparently the problem, almost certainly caused by the use of the chemical.

Needless to say, I feel like an ass for having done this, but would like to get some suggestions as to how I could possibly un-f___k up what I did. Ihad thought of the following options:

- using a brush to carefully re-paint the unpainted surface affected by the chemical with a silver based conductive paint, (I suspect that this could affect the resistance of the driver, but would it be perceivable?)

- using a spray applicator, apl;y a uniform coating to both drivers in order to at least guarantee that one side will be the same as the other in terms of resistance

Finally, if anyone has any "salvage" drivers lying around, please let me know how much you would want for the, Thanks in advance!

Luigi