Well, not quite my way, but a bit diferent !

First of all, i got me some material ... 3mm. felt, thin felt with one sticky side and, some thinck alumium foil [but still flexibile] !

Then i cut parts on shapes and sizes i need !

1. There is one thin sticky felt circle sized on 55mm. like a driver, for the bottom of the cup, to cover a bottom of the cup and prevent sound leak on cup and overhead band joint !

2. 4 pieces of 3 mm. thick felt cut on sizes to cover a holes on the bottom edge of the cup! 3 pieces 41x7 mm. and one 26x7 mm.

3. One sticky felt circle sized on 50mm in diametar to be next to the driver.

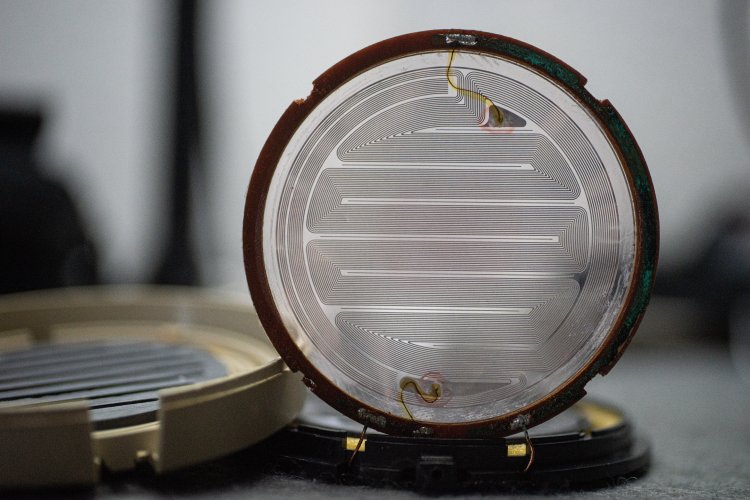

4. One alumium folia circle sized on 50 mm. to stick on 50 mm felt. I decide to use thin gold anodized aluminum **** cuz is more flexibile then postcard paper like i found on some another topic, and wont go bad after some time.

5. One sponge circle sized on driver size - 55 mm. and about 10 mm. thick.

6. 4 pieces of sticky felt sized on cup cover soze and cut on 4 pieces to fit in between screw holes.

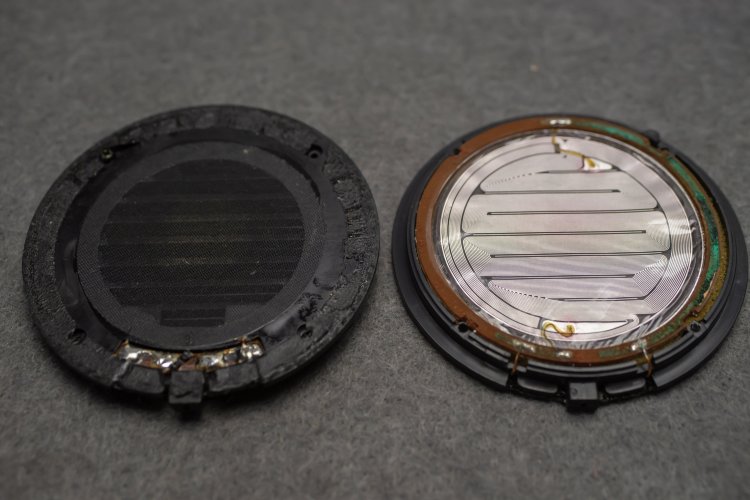

There is pic of all parts in some order how to put inside the cup.

One more pic of parts sorted in order under driver !

Then, i got me some small sticky rubber circles to cover 3 top holes on driver for better high freq.

First thing first, covering the bottom with sticky felt. Is really thin felt and stick really good - feels like decal !

Covering the bottom of the cup and cup-headband joint.

Then - placing new thick felt parts on place between screw holes - covering a holes on the bottom of cup.

Then i stick 4 pieces of sticky felt on the adge of the cup in between screw holes to overlap a bit thick felt, and fold down sticking to same, to keep thick felt in place and tight to cup wall. BUT to dont overlap all te way down - to i dont close holes on the bottom.

Next step is to place sponge in cup ... fits really good - and tight.

Then, stick small felt circle to same size [50 mm.] aluminum cirle, and place over sponge to felt face up.

Finaly - i put driver over all parts.

This is how finished cup looks after placing cover back

I use advice to dont remove old Earpads, and a just unstick places where screw holes are, and after screwing down a cover, HPs looks like they was never open ...

After fiew hours of listening, i am really happy with sound quality compared to stock headphones !

Maybe will try in the future some diferent way - bot for now i am happy ...

Regards !