nick n

Headphoneus Supremus

- Joined

- Feb 3, 2011

- Posts

- 5,369

- Likes

- 1,994

It is a quilt batting material, there is A.Cotton ( 80% Cotton-20% Polyester ) and an A. Bamboo version (50% Natural Bamboo 50% Cotton) , basically a fuzzier felt type material, around the same thickness as felt. A.Bamboo is a little more transparent and slightly thinner, A.Cotton is slightly thicker and fuzzier.

They are my go-to in one form or another between the two of them usually things work out well, and of course in combination with other things often.

http://quiltparadise.ca/products/index.php?Category=Battings

http://store.hamelsfabrics.com/stores_app/Browse_dept_items.asp?Shopper_id=9719329333379719&Store_id=360&Page_id=17&categ_id=6118&parent_ids=0,87&name=Quilt+Batting+-+Arctic+Batting

The first link is the safest and cheapest i would guess ( hard to find decent links! )

If it is a real pain in the butt to source out PM me and I can send a bunch out to you on me since it is relatively cheap and i get it by the metre/yard. Same two types as have been used in here to decent result.

I will make a point of going out tomorrow and getting another yard or two of each to ensure I have enough for a lifetime of mods.

It was part of one of the crucial keys in the main Memory Foam Mod T50rp damping recently posted in the Incremental Mods Thread

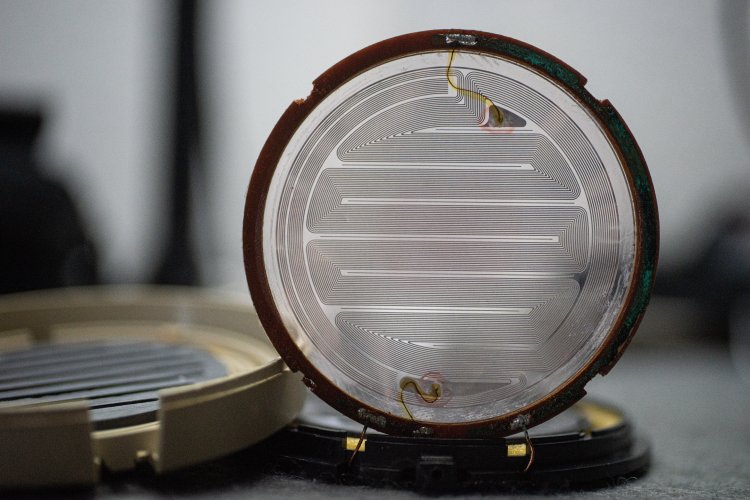

By the way have you ever opened the TDS-7, it scares me. I have seen it open in pictures before and can tell where the tabs are but doing it is another intimidating factor, definitely need opening and tweaking, but I don't wish to botch it up! I can usually get into most things including trouble

They are my go-to in one form or another between the two of them usually things work out well, and of course in combination with other things often.

http://quiltparadise.ca/products/index.php?Category=Battings

http://store.hamelsfabrics.com/stores_app/Browse_dept_items.asp?Shopper_id=9719329333379719&Store_id=360&Page_id=17&categ_id=6118&parent_ids=0,87&name=Quilt+Batting+-+Arctic+Batting

The first link is the safest and cheapest i would guess ( hard to find decent links! )

If it is a real pain in the butt to source out PM me and I can send a bunch out to you on me since it is relatively cheap and i get it by the metre/yard. Same two types as have been used in here to decent result.

I will make a point of going out tomorrow and getting another yard or two of each to ensure I have enough for a lifetime of mods.

It was part of one of the crucial keys in the main Memory Foam Mod T50rp damping recently posted in the Incremental Mods Thread

By the way have you ever opened the TDS-7, it scares me. I have seen it open in pictures before and can tell where the tabs are but doing it is another intimidating factor, definitely need opening and tweaking, but I don't wish to botch it up! I can usually get into most things including trouble