Here's a sequence showing the disassembly of the damping pads and the original foam pads. Everything's pretty squashed after being inside for 20 years, and the foam and felt have both molded themselves to the inside of the cup. They eventually resemble the vacuum-formed soundproofing pads installed in cars at the factory.

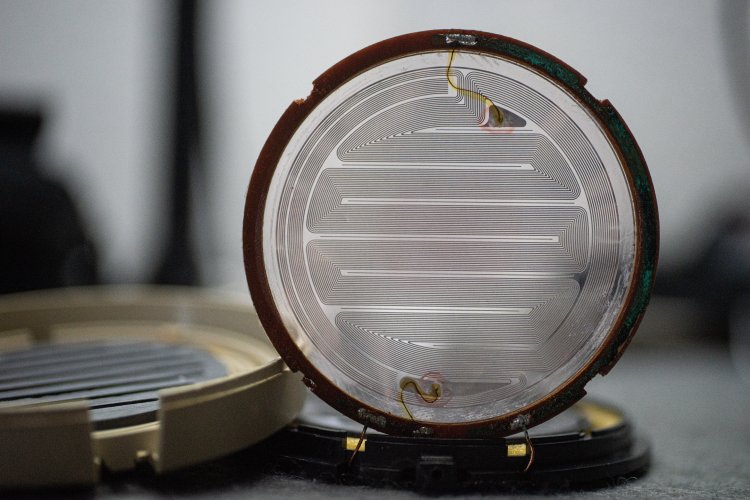

Interestingly, the Pro 30 is vented not only around the circumference of the black plastic driver cup but also, very sneakily, around the circumference of the aluminum cap. You can just see a tiny gap in the photo in my previous post. Here's a photo (by JadeEast) of the Pro 30's public face without its snazzy aluminum cap. Strange but somehow beautiful.

Much better mechanical design than the Yamahas, as you'll see.

There are [only] 3 decent-sized rustproof screws holding the cup halves (earcup and driver cup) together. As usual, the screw heads are hidden underneath the outer circumference of the earpads, which do not have to be removed to gain access. The sequence begins with the earcup facing down and the driver cup (the part with the aluminum cap) lifted off.

(1) What you see at first is all felt:

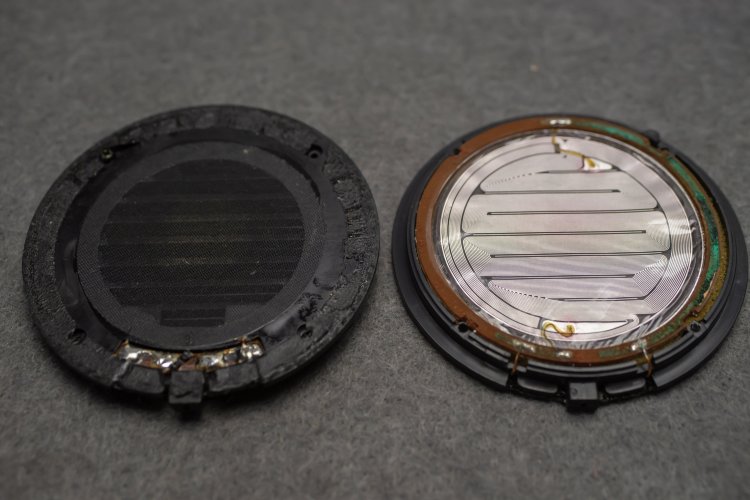

(2) We've removed that felt disc you saw on top and a smaller black original foam disc that was underneath it (it's visible at left); they covered the cap vents.

(3) We've removed the ring of felt that covered the circumferential vents. You're seeing the original main disc of foam the 'phones came with. Now it's squashed like everything else and no longer makes a very good spring.

(4) I've taken that original foam from the photo above and turned it upside down to show the felt damping disc that was underneath, next to the driver.

(5) We can't forget the auxiliary foam spring necessary to hold the felt damping disc tightly against the driver. This wasn't necessary when the 'phones were new, but it is now. If you look closely you'll see that the pink foam shown is mostly closed-cell (too many sparkly highlights) and therefore unsuitable. So this is for illustrative purposes only. If you can get some aquarium-filter "

fishfoam", use it.

(6) Finally, here's the driver with its integral damping pad sitting in its clamp. There's an actual gasket underneath that seals the driver to its baffle-- very important for bass.

As I was finishing this up I saw that ericj has posted photos of his damping bits. Compare and contrast among yourselves.

Again, the aim of this mod, as with all my mods, was to improve the sound but to be completely reversible. For example, the large factory foam disc could have its center cut out so it could be dedicated to the task of keeping pressure on the vent damping ring, but I wanted to keep everything as it was so modders would have the option of going back to stock.

Team Critical Damping!

UPDATE: It turns out that the extra-dense felt ericj found in the remnant bin at the fabric store was too dense for the Pro 30. I've added a warning about the signs of overdamping to post #83. Fortunately, fabric stores all seem to have the cheap acrylic felt that I've been using. About a dollar a sheet, comes in a wide variety of colors. I bet that dense felt would be perfect for the Fostex T20v2 and Yamaha HP/YH-3 and YH-50, though.

UPDATE 2: I noticed when I reassembled my Pro 30 that it had developed a tendency toward overly ripe midbass, thus the advice to add fresh stiff opencell (aka reticulated) foam to keep the damping layer firmly pressed against the driver. The foam needed is fully open-cell and ~6-13mm thick. Ideally it should project at least twice as far above the clamp as the height of the clamp itself. This is to keep from pulling the large factory foam disc in from the perimeter. The factory black foam disc shown above is about the minimum thickness needed, but I don't recommend using it because its age renders it prone to collapse-- some of mine are as flat as a piece of paper. In fact, it wouldn't hurt to replace

all factory foam with new stuff.

INTERESTING THOUGHT: Hmm, a loose damping layer pumps up midbass... could come in handy those times when you need to add some warmth to the sound of a particular 'phone...

.