lcsaszar

New Head-Fier

- Joined

- Mar 2, 2007

- Posts

- 8

- Likes

- 10

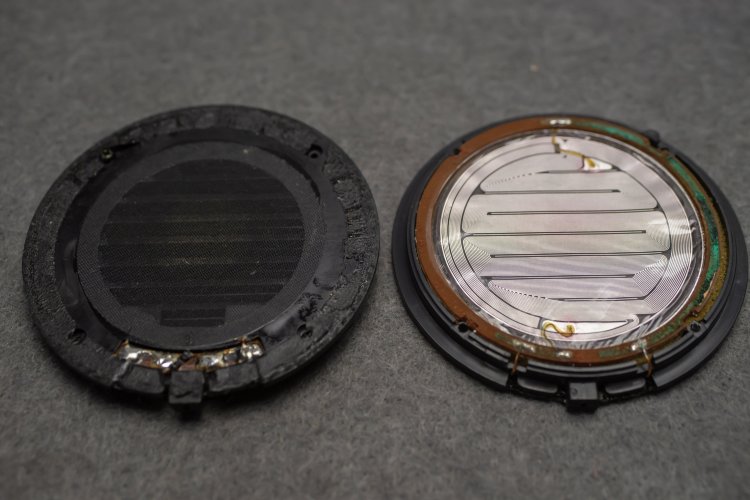

I am also a proud owner of a pair of Peerless PMB 100. I purhased them from Germany, and of course I disassembled and inspected them inside. I also recabled them internally, painted the internal felt black and repainted the rear metal grille. I replaced the ear foam with thin perlon wool covered with loudspeaker silk. Its sound is great, but its comfort is not the best. It tends to fall down from one's head if not sitting straight (e.g. in laying position). Also they are lacking bass.

I played around a bit with an audio signal generator. The falling of bass is noticeable below 100 Hz, and no sound can be heard at 20 Hz. I am very interested how could be the bass boosted with the holes covering or internal felt trick.

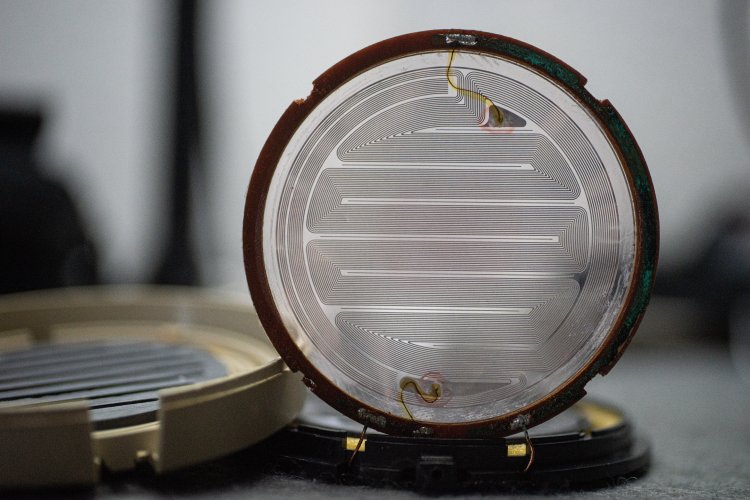

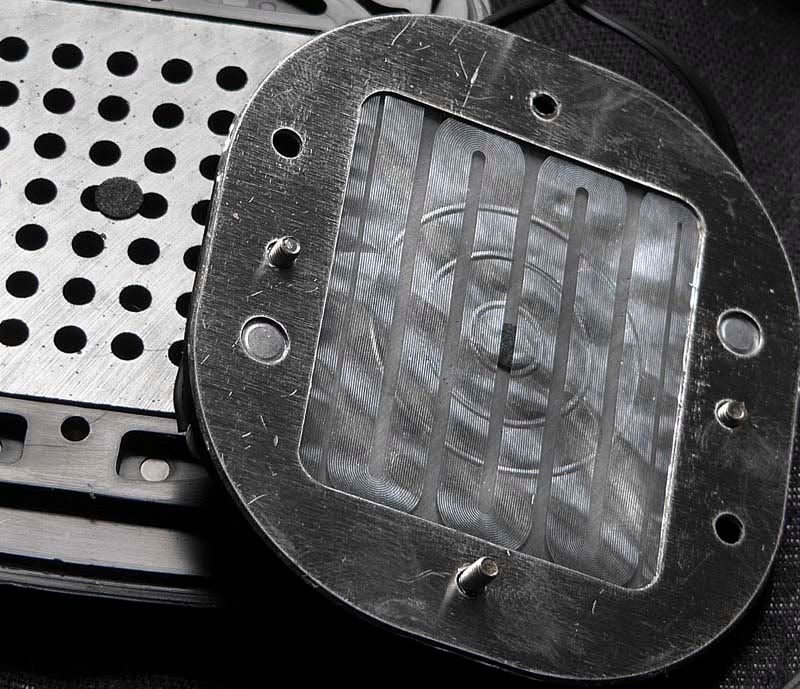

I have (had ) another set of ortos, the Technics EAH-820. It has rectangular diaphragm. Unfortunately one side is broken. Could someone give me some advice how can I replace/repair it? I removed the good diphragm, and it could be used as a template for photograhic duplicating. I even purchased some thin aluminium-covered plastic foil, that seems to be similar in thickness. Now I have to transfer the pattern from the good diphragm to the foil with some photoresist method, then etching it. Here is a photograph of the diaphragm:

) another set of ortos, the Technics EAH-820. It has rectangular diaphragm. Unfortunately one side is broken. Could someone give me some advice how can I replace/repair it? I removed the good diphragm, and it could be used as a template for photograhic duplicating. I even purchased some thin aluminium-covered plastic foil, that seems to be similar in thickness. Now I have to transfer the pattern from the good diphragm to the foil with some photoresist method, then etching it. Here is a photograph of the diaphragm:

http://tube.fw.hu/Technics_diaphragm.jpg

I played around a bit with an audio signal generator. The falling of bass is noticeable below 100 Hz, and no sound can be heard at 20 Hz. I am very interested how could be the bass boosted with the holes covering or internal felt trick.

I have (had

) another set of ortos, the Technics EAH-820. It has rectangular diaphragm. Unfortunately one side is broken. Could someone give me some advice how can I replace/repair it? I removed the good diphragm, and it could be used as a template for photograhic duplicating. I even purchased some thin aluminium-covered plastic foil, that seems to be similar in thickness. Now I have to transfer the pattern from the good diphragm to the foil with some photoresist method, then etching it. Here is a photograph of the diaphragm:

) another set of ortos, the Technics EAH-820. It has rectangular diaphragm. Unfortunately one side is broken. Could someone give me some advice how can I replace/repair it? I removed the good diphragm, and it could be used as a template for photograhic duplicating. I even purchased some thin aluminium-covered plastic foil, that seems to be similar in thickness. Now I have to transfer the pattern from the good diphragm to the foil with some photoresist method, then etching it. Here is a photograph of the diaphragm:http://tube.fw.hu/Technics_diaphragm.jpg