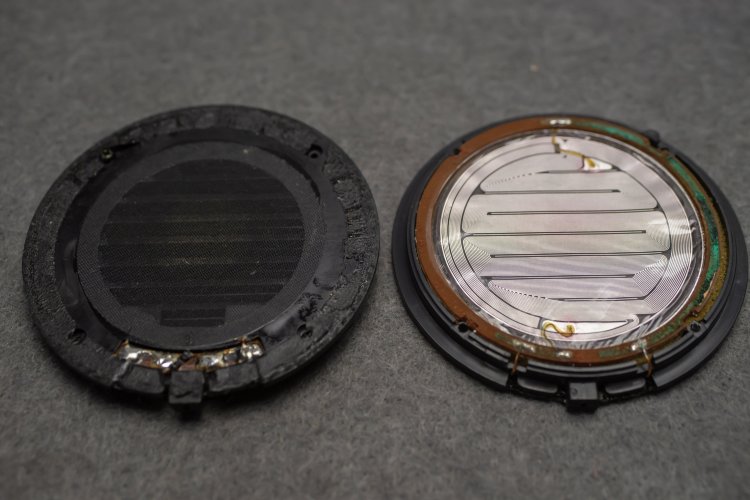

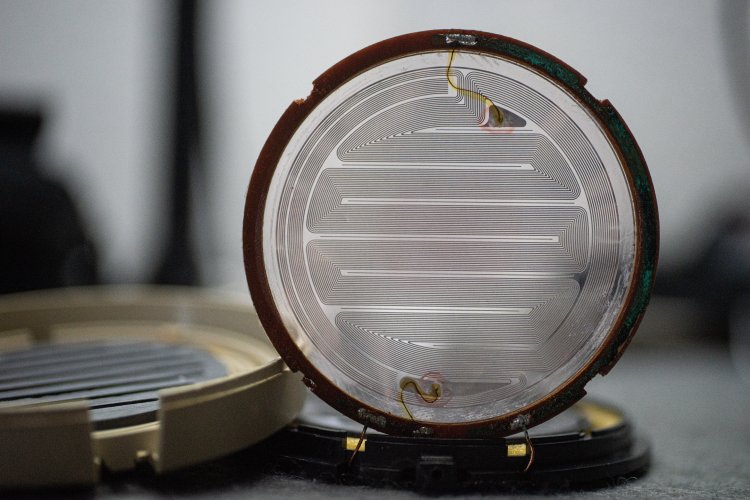

Bare drivers, both sides, with the strain relief attached.

I didn't know which side was left or right on the shell as I don't personally know Russian. However, using google translate yielded this:

So this must mean that this is the right side.

Damped the cup vents using the felt and placed the wool at the back of the cup, like it was stock.

Stuck the driver in. However, I was worried that the cable leading out would catch on the baffles.

So I tucked the cable underneath the driver before placing it in the cup and putting the strain relief in its proper place in the cup. There was also a small piece of foam sealing the cup from the hole for the cable so I replaced it.

I used the baffle and screws from the TDS-5 and attached it to the TDS-5M cups because I hate phillips-head screws and forgot to pick new ones up at the hardware store.

Same deal with the left cup.

Stuck on the TDS-5 pads as the TDS-5M pads were shot, and I'm done.