Faust2D

Headphoneus Supremus

- Joined

- Apr 9, 2007

- Posts

- 3,042

- Likes

- 26

Quote:

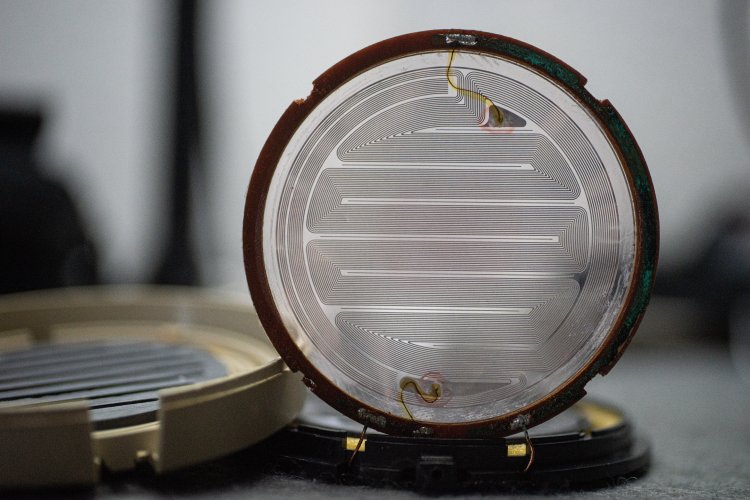

From in production stats ESP950 has the largest diaphragm radiating surface area: 46.6 sq. cm.

I am not sure what SR-007's radiating surface area is, but I believe it has a slightly smaller driver.

| Originally Posted by cetoole /img/forum/go_quote.gif Is that as big as the high end 'stats get? Dang, I thought they were bigger. My SR404 looks to be about 90mm high, but only half that wide, if I am even measuring the right place. Havnt opened them up or anything, I can just see the red ring inside, and figured that was the outer clamp for the stators. No idea though on the other big stats, ESP/950, O2, or HE90. |

From in production stats ESP950 has the largest diaphragm radiating surface area: 46.6 sq. cm.

I am not sure what SR-007's radiating surface area is, but I believe it has a slightly smaller driver.