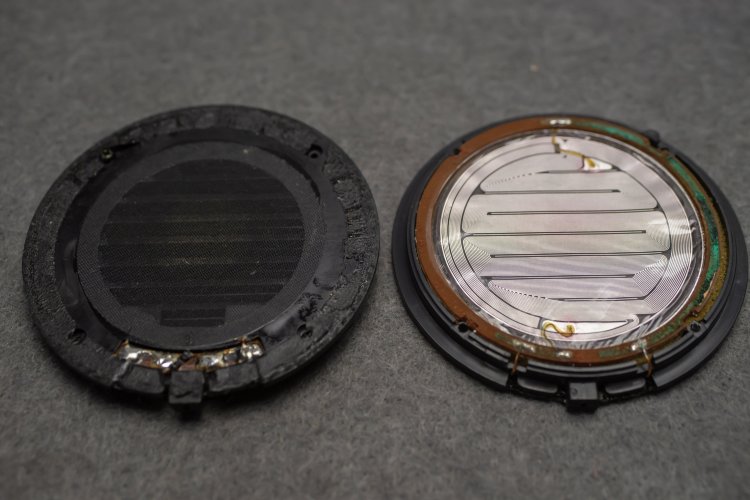

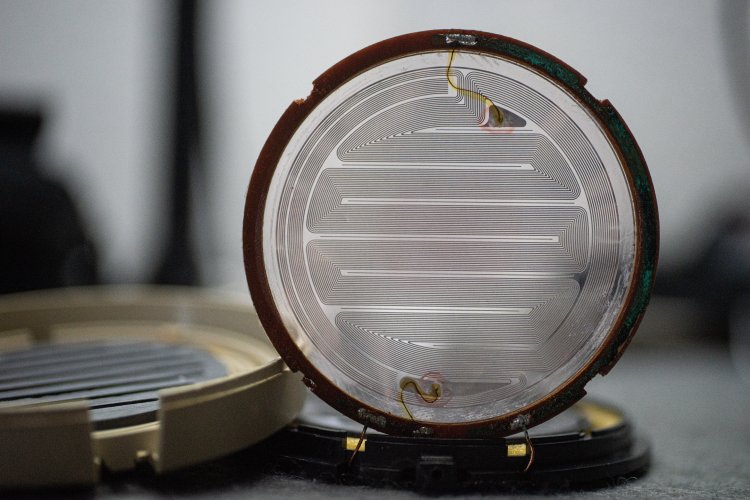

Was doing some maintenance over the past few days.

I really believe Yamaha had some of the best engineers working on their 70s headphones.

The mechanical clutch system for adjusting the cup sliders is just beautiful.

How did you disassemble the ball joint?

Unfortunately mine was broken

I need to repair them but I have a problem in disassemble this part