Hayduke

1000+ Head-Fier

- Joined

- Dec 15, 2006

- Posts

- 1,125

- Likes

- 10

Quote:

FYI...

This is one of the few items I can get local. My local Ace/Homeco carries these nylon bushing in the hardware isle (where the nuts and bolts are). If you have an Ace nearby, you might wanna check if they have them. Home Depot near me does NOT carry anything like this though

| Originally Posted by tomb /img/forum/go_quote.gif It's not grommets, but hole bushings. I used these on one of the SSMH PCB prototypes (the black one):

They were used on the Millett MAX (prototype in pic):

but their use first started way back on the revMH Millett Hybrid:

n_maher came up with the idea as a way to cover his nasty tube holes.

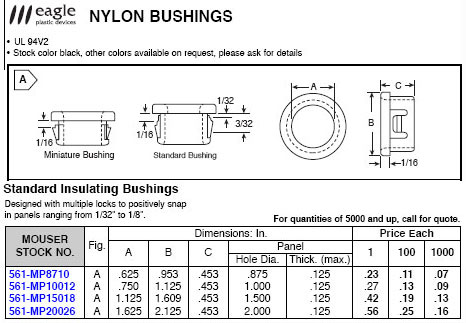

Here's the specific info: Mouser Part #561-MP10012 and the catalog diagram:

You want to cut a 1" hole. These snap in, leaving a 3/4" hole opening for the tubes - just perfect.

|

FYI...

This is one of the few items I can get local. My local Ace/Homeco carries these nylon bushing in the hardware isle (where the nuts and bolts are). If you have an Ace nearby, you might wanna check if they have them. Home Depot near me does NOT carry anything like this though