- Joined

- Jun 9, 2014

- Posts

- 53

- Likes

- 10

Yeah, Jerg is right.

I think some people mistook the other one for your shelf-liner, Jerg... and that would probably explain the diversity in opinions.

The 2 liner materials sound... very different IMO. Even if measurements don't show them as different, they do sound different subjectively.

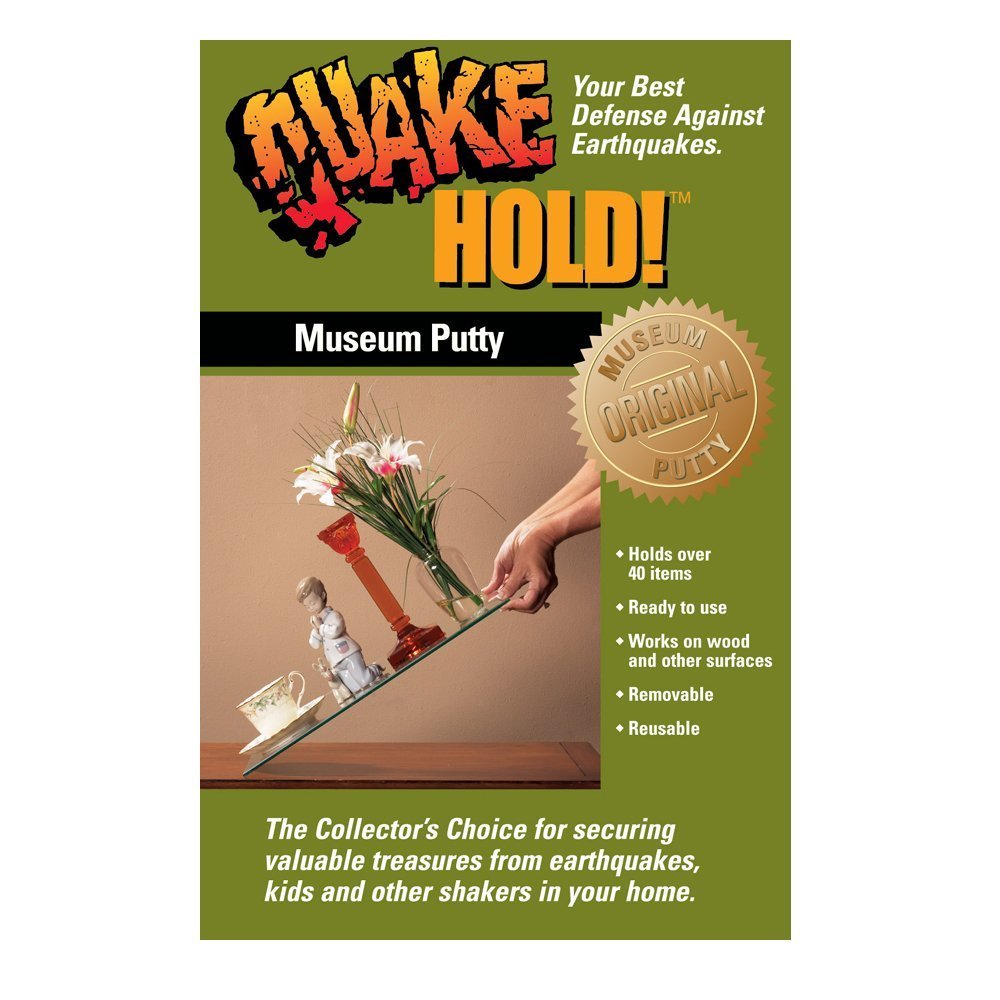

Has anyone played with an alternative to mod #3 besides the tacky stuff? Maybe the use of some rubber padding to make good contact between plastics or maybe even dynamat?

I'm getting mod 1 and 2 underway. Mod 1 first then maybe mod 2 tonight but I could take it in steps instead of all at once.

Senn uses sheet plastic on the HD800... I've always had the thought of just attaching some plastic from a ziplock bag to the pads to create a better seal. If it works for them...

Not a great picture, but you can get an idea...

Yeah sheet plastic cutouts could be a good alternative. Just permanently glue it to the bottom surface (avoiding the 4 clip regions), then bond the new surface to the cup baffles via double-sided tape as per usual.

You could probably get away with double sided tape, but glue would probably hold up better.