Houseg1011

New Head-Fier

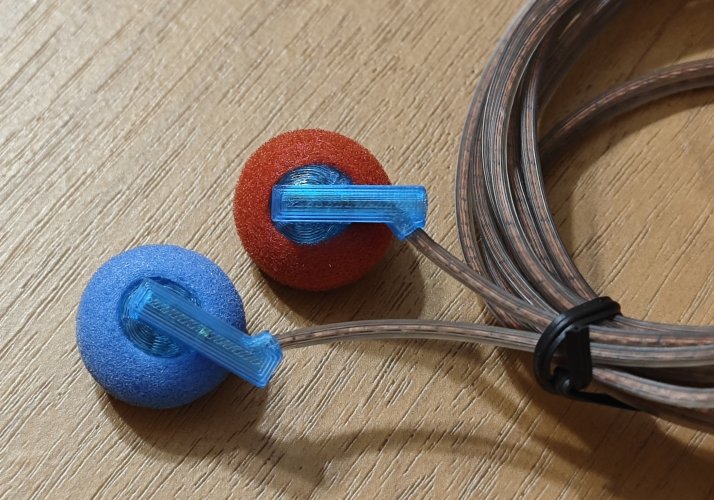

Hehe. Its not very pretty. But it works great! This wire has a surprisingly bright tone for pure copper.

edit: The reason it is so bright despite being clear? almost a..... silver cable tone with bass?! the cable has a resistance of under 1.5 ohms!!!! I've never worked with headphone wire this low resistance. This will be very interesting.

may i ask for the link where you bought this