golov17

Headphoneus Supremus

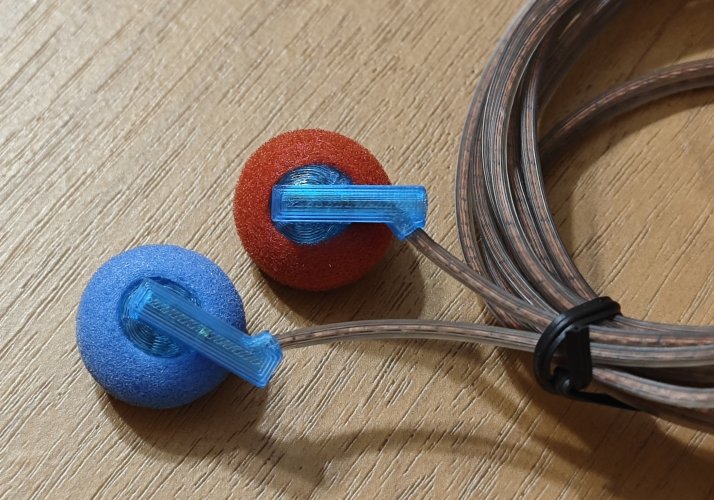

http://www.audiocheck.net/audiotests_polaritycheck.phpDear, do you have test tracks or easy check technique to see when one channel is reverse polarity? I find it hard to hear obvious differences. But I'm not 100% sure I wired right. Thanks