FYJX

Previously known as MaoDi

Quote:

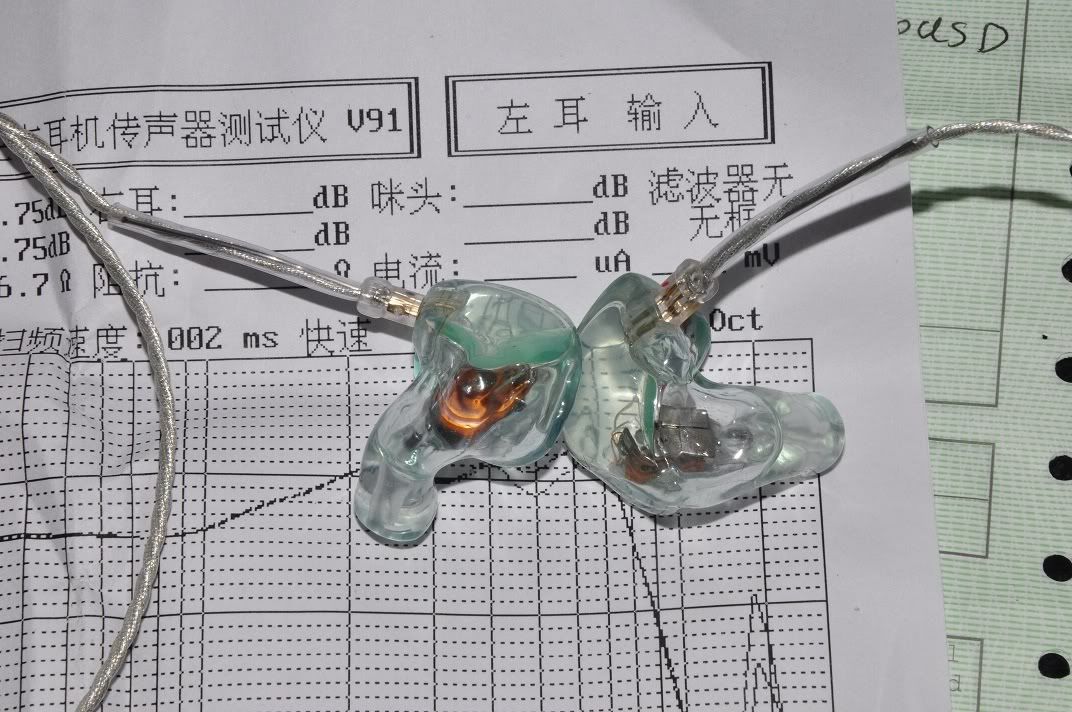

The air chamber is a marketing spec. I've seen the inside of the q-Jays, there's just extra space behind the driver for air to move. There'd be an infinite amoutn of space for the driver after remold.

| Originally Posted by SpudHarris /img/forum/go_quote.gif Thanks Felix. I've chickened out of having the Q-jays done also as I think they would really need another driver to sound decent remoulded, something to do with an air chamber in the original phones that helps with the bass that would obviously be missing if remoulded. |

The air chamber is a marketing spec. I've seen the inside of the q-Jays, there's just extra space behind the driver for air to move. There'd be an infinite amoutn of space for the driver after remold.