Because stupid double post feature I am posting here for more reach and feedback instead of editing my post in the slow moving poor man’s Stax thread.

==============

@ludoo @gammi

252s vs SRD-7

^ averaged frequency response measurements, modded SR-X1, graph to highlight the differences only

Did I notice a difference subjectively? No.

The measured difference in high frequencies appears to trend with others within this thread whove measured and compared SRD7mk2 vs Stax amps. I suppose this possible tonal difference may be a pro or con depending on user and system.

I did notice that the 252s (with uprated power supply) could seemingly get louder than my SRD7mk2 (modded and paired with Schitt Rekkr 2W @ 8ohm) based on how much pre-amp (Saga2) volume was needed to reach 90dB. I intend to sell SRD7mk2 and save on desk space, dm me if interested, Ill create a classified soon.

==========

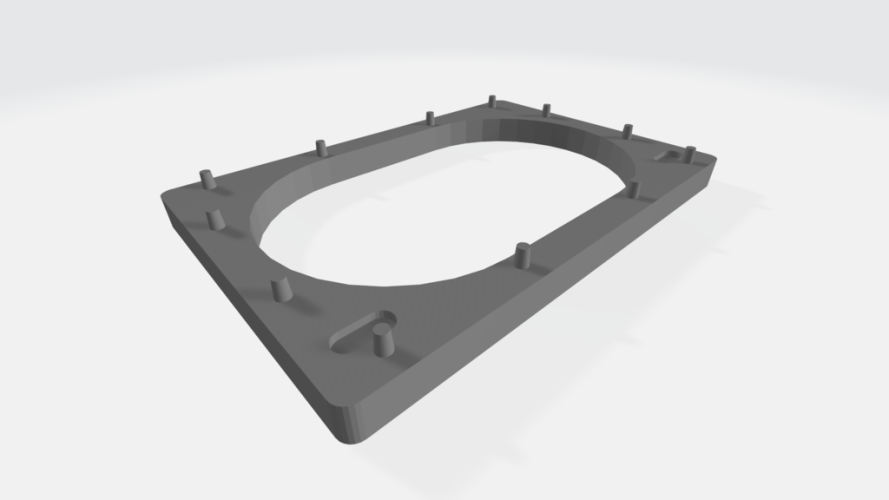

I want to padroll SR-207 so started by creating a pad adapter for common 100mm round pads.

Having previously owned the SOCAS pad adapter for L500, I assumed that the procedure would be the same which involves unscrewing the stock pad mount. And so I removed stock pads and screws from 207 but I was unable to get the stock pad mount to come off. I figured maybe it was just stuck from overfill adhesive from the stock pads. But after some prying then quick investigating I saw SOCAS x07 series pad adapter instructions were different and doesnt call for unscrewing anything but just stickying the pad adapter on to the stock pad mount. Does this mean I cant easily remove stock pad mount and should just do as SOCAS recommends?

Not a big deal to just adhesive the new pad mount on except that it adds an extra few mm to pad depth. I just like the idea of having them screwed-in.

Test fitting:

^ Oval pads make more sense for the shape of Lambda enclosure so will try that next. I just have so many more spare round pads to choose from that I wanted to try those first.

==============

@ludoo @gammi

252s vs SRD-7

^ averaged frequency response measurements, modded SR-X1, graph to highlight the differences only

Did I notice a difference subjectively? No.

The measured difference in high frequencies appears to trend with others within this thread whove measured and compared SRD7mk2 vs Stax amps. I suppose this possible tonal difference may be a pro or con depending on user and system.

I did notice that the 252s (with uprated power supply) could seemingly get louder than my SRD7mk2 (modded and paired with Schitt Rekkr 2W @ 8ohm) based on how much pre-amp (Saga2) volume was needed to reach 90dB. I intend to sell SRD7mk2 and save on desk space, dm me if interested, Ill create a classified soon.

==========

I want to padroll SR-207 so started by creating a pad adapter for common 100mm round pads.

Having previously owned the SOCAS pad adapter for L500, I assumed that the procedure would be the same which involves unscrewing the stock pad mount. And so I removed stock pads and screws from 207 but I was unable to get the stock pad mount to come off. I figured maybe it was just stuck from overfill adhesive from the stock pads. But after some prying then quick investigating I saw SOCAS x07 series pad adapter instructions were different and doesnt call for unscrewing anything but just stickying the pad adapter on to the stock pad mount. Does this mean I cant easily remove stock pad mount and should just do as SOCAS recommends?

Not a big deal to just adhesive the new pad mount on except that it adds an extra few mm to pad depth. I just like the idea of having them screwed-in.

Test fitting:

^ Oval pads make more sense for the shape of Lambda enclosure so will try that next. I just have so many more spare round pads to choose from that I wanted to try those first.