Sonywalkmanuser

Headphoneus Supremus

https://advancedplatingtech.com/blo...gold-vs-silver-plated-connectors-or-contacts/

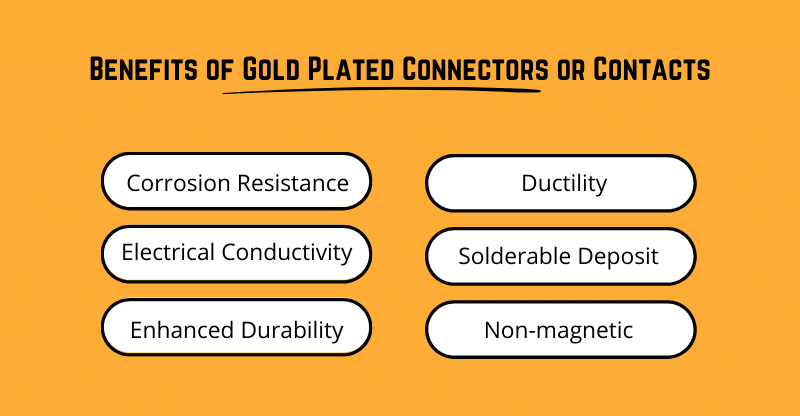

The Benefits of Gold-Plated Connectors

Gold is a highly noble (unreactive) metal that can enhance the performance of connectors in a variety of electrical applications. The benefits of using gold-plating include:

Superior Corrosion Resistance

In comparison with other metals, gold’s resistance to oxidation or corrosion is extremely high. In situations where the contacts of a connector are likely to be exposed to corrosive substances or conditions, gold plating can serve as an effective barrier from oxidation and corrosion. As a result, gold-plated connectors are an excellent choice for more corrosive applications where the connector or contact may be exposed. Applications include high humidity environments or applications with frequent thermal cycling as well as exposure to corrosive salts or acids. In the later application, a heavier gold deposit or even duplex gold deposit may be required to ensure there is sufficient gold to eliminate any porosity in the deposit thereby forming an effective barrier to corrosion.

Applications include high humidity environments or applications with frequent thermal cycling as well as exposure to corrosive salts or acids. In the later application, a heavier gold deposit or even duplex gold deposit may be required to ensure there is sufficient gold to eliminate any porosity in the deposit thereby forming an effective barrier to corrosion.High Electrical Conductivity

Besides copper and silver, gold is the third most conductive metal in the world. However, gold does not produce any oxides or other compounds, so it maintains its high conductivity even at elevated temperatures or when exposed to corrosive environments. The high/consistent conductivity of gold ensures stable current flow even at very low voltages making gold an excellent choice for electronic applications where milli-volts transmit milli-amps.Enhanced Durability

Electroplated gold can be alloyed with small amounts of nickel or cobalt to increase the hardness from that of pure gold (< 90 Knoop) to as high as 200 Knoop. This hardened gold deposit is commonly referred to as hard gold. When plated to a sufficient thickness (> 50uin) over an electrolytic or electroless nickel base, hard gold can provide a durable and coating for repeated connection cycles. Hard gold is not prone to fretting or galling due to its natural lubricity.Ductility

Because gold is such a malleable metal, it’s suitable for flexible connections and springs. Gold’s ductility makes it more likely that plating will hold up to multiple cycles of contact. However, gold-plated electrical connectors or springs require a suitable underplate material to guarantee the finish meets the design requirements. It is generally recommended that an engineered nickel such as a sulfamate nickel be used as an underplate to gold when a plating a flexible contact or spring.Solderable Deposit

Gold plating is an excellent finish for forming reliable solder joints and will consistently and evenly wet with using just a mild rosin flux without acid activation. Gold can be plated on nearly any substrate including stainless steel terminals or connectors to allow for subsequent joining through soldering. Generally, only a thin deposit of soft gold of 0.00001 inches per side is required to form a reliable solderable gold contact but heavier gold deposits can be soldered as well.When soldering to a gold electrodeposit, the gold plating diffuses into the solder joint through a mechanism called solid-state diffusion. Because of this phenomenon, care should be taken to not exceed more than 3% by weight gold in the solder joint as this can cause embrittlement within the joint itself. As a general rule deposits of < 0.00005 inches per side will result in less than 3% by weight gold in the solder joint

Non-magnetic

As a final point, gold is not magnetic. This is advantageous in scenarios where electromagnetic fields can create interference. For instance, gold plating may be suitable for connectors used in medical equipment like Magnetic Resonance Imaging (MRI) scanners.Industry Applications of Gold-Plated Connectors or Contacts

Most the electronic devices we rely on each day utilize gold-plated contacts or terminals. In addition to gold’s attractive, value-added appearance, this precious metal has several key properties that make it a valuable material across many industries. However, the electronics and interconnect industries are the primary user of gold. It performs an essential function in keeping electronic components working effectively over time.

Gold can be found in various electrical devices, including cell phones, desktops, and laptops. For every 10,000 smartphones, there are about ten troy ounces (or 3/5 pounds) of gold. There are approximately five troy ounces of gold worth over $9,000 in 200 computers.

Because of its capacity to maintain electrical connectivity, gold is well-suited for use in a wide range of electronic applications. It can be applied to any part of a device that requires a reliable electrical connection. External components such as electrical connectors most commonly feature gold plating. However, gold is primarily used in the circuit boards of electronic devices.

The reliability of any device is dependent on the integrity of its circuit board connections. As such, electronics manufacturers apply gold plating to their circuit boards to improve conductivity and prevent corrosion. 99.9% pure gold plating or soft gold, as it is called, is commonly used in pad connections or where wire bonding is required.