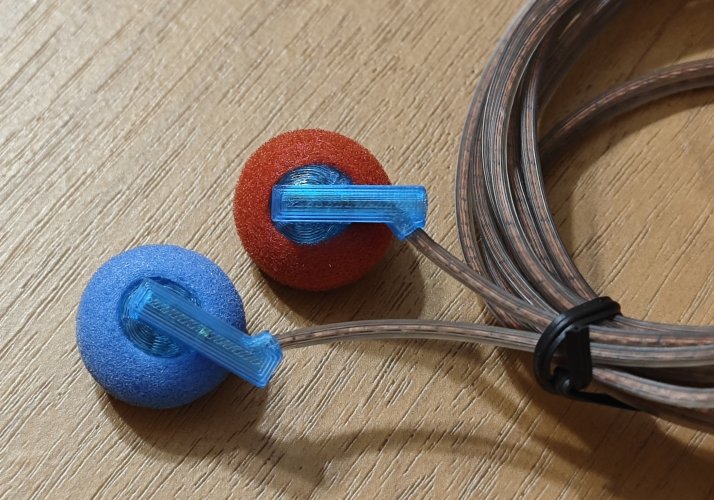

I finished converting one of my old Blox YIN/TM9 cable into MMCX. I'm pleased with both sonical result and look

Currently using it with my 32ohm build at work. I really enjoy the softness if this cable.

But at the end I just realized that I inversed the red mark (R) with the white (L), lol. Anyway nothing major as its just for me ^^

Currently using it with my 32ohm build at work. I really enjoy the softness if this cable.

But at the end I just realized that I inversed the red mark (R) with the white (L), lol. Anyway nothing major as its just for me ^^

I'm using E8000 glue to set drivers into shells correctly (easy to open remove if needed after). For something more strong I was using cyanolite in the past but not recommended as sometimes it makes white areas on the edges of the shells that is difficult to remove. I thing best way is using epoxy glue for better results (I still need to find where to buy).Quick question guys.. what glue to use in making earbuds? Prefer if you would also state the brand, thanks.

Last edited:

I will post the picture tomorrow.

I will post the picture tomorrow.