chrislangley4253

Headphoneus Supremus

- Joined

- Dec 16, 2009

- Posts

- 2,509

- Likes

- 53

Quote:

meh. I've had the pa2v2 and didn't like it. I'd go with a CMOY

what didn't you like?

meh. I've had the pa2v2 and didn't like it. I'd go with a CMOY

what didn't you like?

Thanks guys! Bill has suggested the same thing and I'm going to just get rid of the plastic and add wood and keep the aluminums, it should sound very nice when its done. I got in touch with Bilavideo and he has offered to send some my way!

meh. I've had the pa2v2 and didn't like it. I'd go with a CMOY

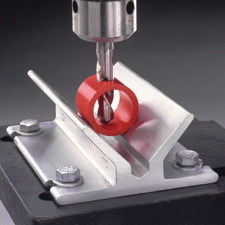

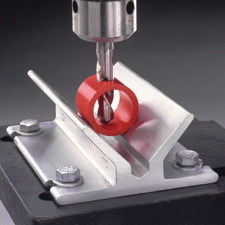

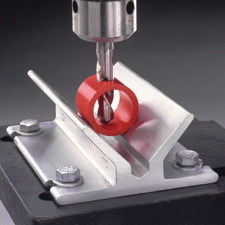

Hey bill, if you want a nice center point on those shells for the gimbal mounts, how about getting one of these?

Seems to be a nice way to just drop a hole straight through.

Hey bill, if you want a nice center point on those shells for the gimbal mounts, how about getting one of these?

Seems to be a nice way to just drop a hole straight through.

Nice fine. Though, if I were to use it, I'd be using extreme care. On some of thinner shells, I'd be a bit worried that the bit would tear them up. However, I guess they key being - use a sharp bit, work slow and let the bit do the boring and not apply too much pressure and you are dropping the bit in to cut through the material.

anyone here using the listening station medium pouch?

Any good protection wise? I'd just like to protect the wood.

And now a question for you guys. Has anybody ever cut with a router and template? If so, are you buying the template or making it? Cutting with a router seems like it could provide a cleaner edge than a hole saw (prior to sanding anyway)

i saw that case.

how much did you pay for it? and does it rub against the rod tips?