SomeGuyDude

Headphoneus Supremus

- Joined

- Jun 24, 2012

- Posts

- 7,595

- Likes

- 3,423

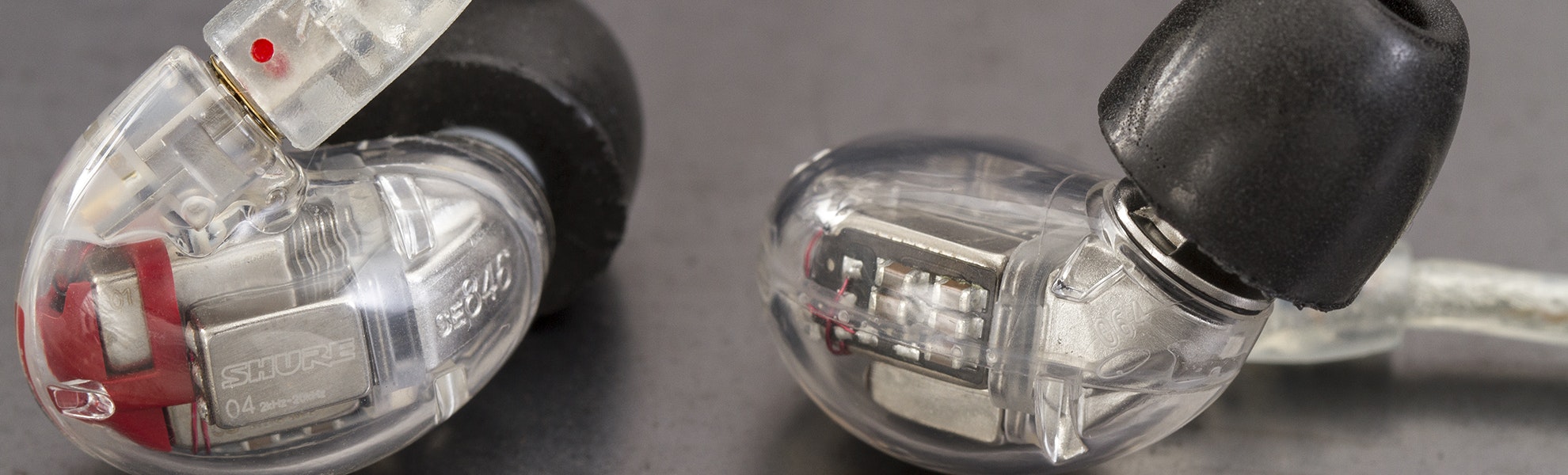

After reading your post... i went to look at my 846...

to my horror... both sides of my 846 has the same bridged soldering...

is it supposed to be bridged or this is a manufacturing error?

So do both of mine. I also dug around and it looks like that soldering is on every image as far as I can tell. If anything, the error might be that the soldering popped off on this one, or equally possible is that it has less to do with the sound than we think. It's not like we know exactly how these things function.