Another mild update! So basically, I said I had bought some photoresist film and was wondering when it would arrive.. I found it in the saved section of my amazon basket. Oops! So now that has actually been ordered and will be arriving soon.

Instead, I chose to finally wire up the little Starving Student tube amplifier that I used to teach myself PCB design basics.

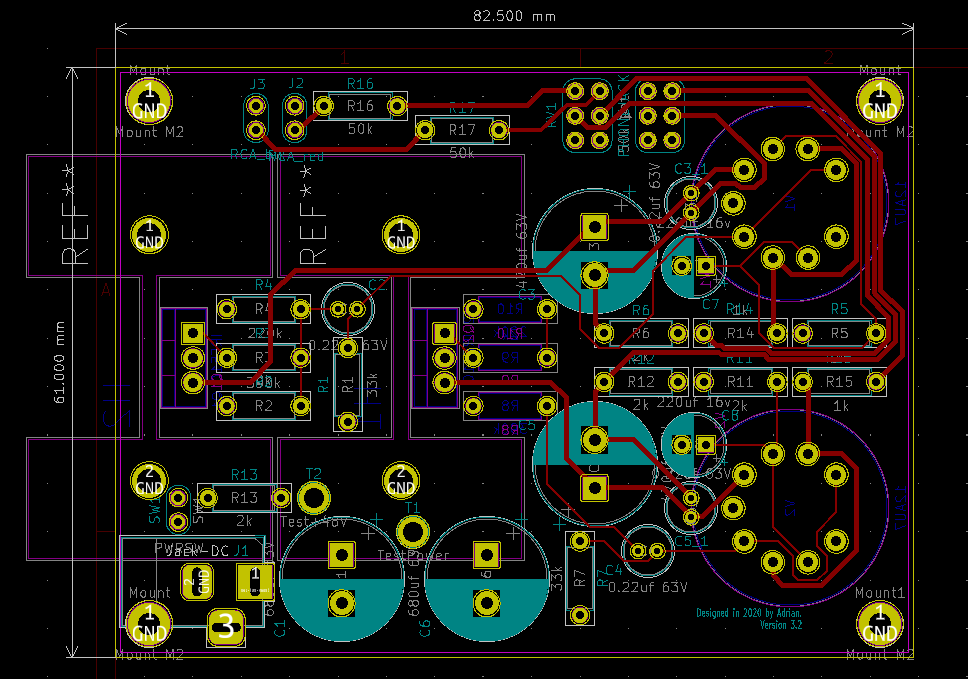

There is the schematic I used. It is basically just Dsavitsk's schematic but I moved some stuff around and added labels to make it look like I had actually done something useful.

So I turned that schematic into that. I think it looks neat though I'm plenty sure I've made many mistakes. Too bad, I already have the boards.

I love oshpark's purple colour

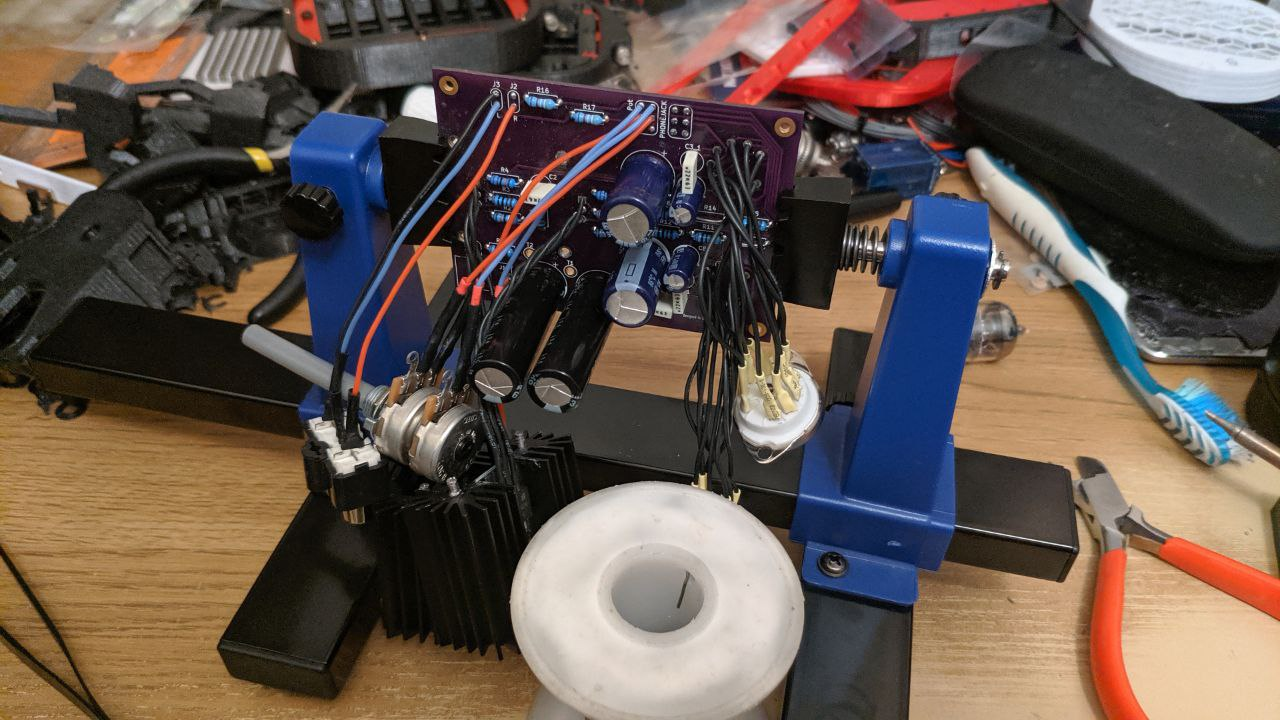

And since I already had all the components, I started to populate the board.

Tube sockets were next, as was the pot, the headphone jack, the barrel jack and a switch. Those I decided to use wires instead of directly mounting on the PCB to give me options when mounting the PCB and all that. When that was done, I did the first smoke test. Nothing exploded! Or so I thought. One of the MOSFETs had quit and that had resulted in the left channel just not working and all that. (Also in the picture you'll notice I wired the pot wrong. That was a quick fix). So, now I'm waiting for a new set of MOSFETs because I foolishly didn't order spares as well.

The headphones are still being worked on! Just.. Slowly. Need to get the photoresist film and make that work with the mylar film, then I need to figure out etching and all that. Hopefully that works. If not, well, maybe I'll just try drawing out my coils! In the meantime, I think I can also work on making my KSC75s have a detachable cable and, well, making cables for that. Maybe I could do the same for my K612 Pros! But, I think I shouldn't bite off more than I can chew.

And since I already had all the components, I started to populate the board.

And since I already had all the components, I started to populate the board.