chinsettawong

Headphoneus Supremus

Your frames look super nice. Congratulations!

Wachara C.

Wachara C.

I'm really itching to try to make a pair of really small, in ear, type of electrostatic earphones - similar to Stax SR002. Does anyone have any experience on how they sound?

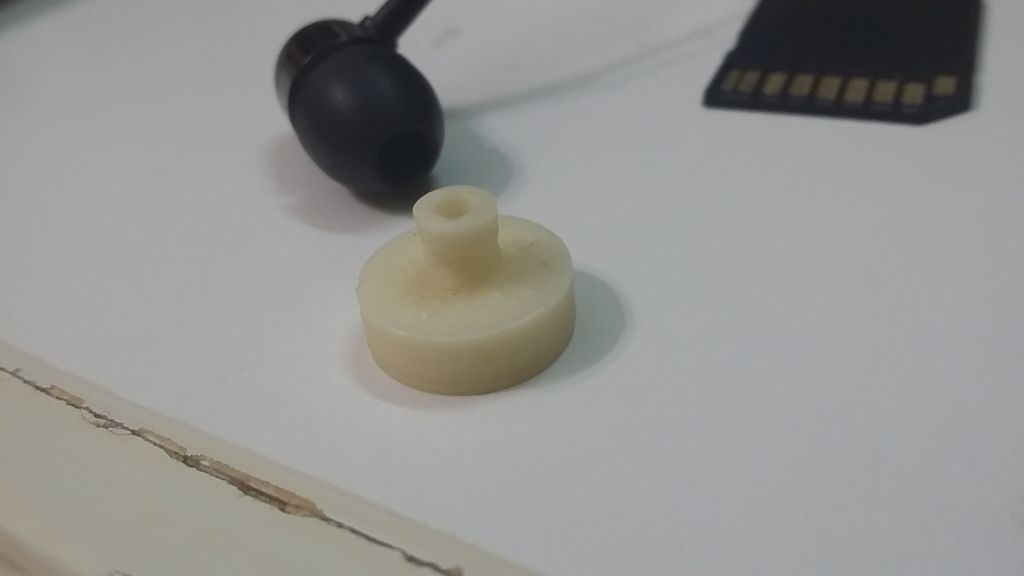

I can use my 3d printer to print the housing. I'm thinking of 0.75 mm holes on the stators and 0.5 mm spacers. I would like to use the amps I have which all have bias voltage of 580V.

It would be fun to try something different. What do you guys think?

Wachara C.

Hi geemo,

It would be a great help if you could share with me some photos and measurements of the driver. What I really like to kmow is the spacer thickness and the diameter of the active diaphragm.

Thanks for your help.

I just went out to buy a 0.5 mm endmill. Boy, it is so mall and fragile. I'm not sure if my CNC can handle it. We'll see.

Wachara C.