You can do that, or you can separate the venting chambers.I see! Never noticed this. Does the air from the front vent end up in the shell, together with the air from the back vent? and then you release it with a hole/vent in the shell?

Sorry, slow learner here... Quite impressive how you managed to print that thin tube from the DD with out clogging it. Especially with translucent resin. I guess resin calibration is the key...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Home-Made IEMs

- Thread starter Bilavideo

- Start date

mattmatt

100+ Head-Fier

- Joined

- Feb 11, 2012

- Posts

- 456

- Likes

- 282

By separating venting chambers, what do you mean?You can do that, or you can separate the venting chambers.

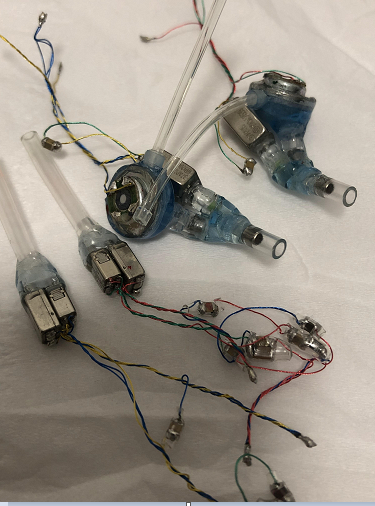

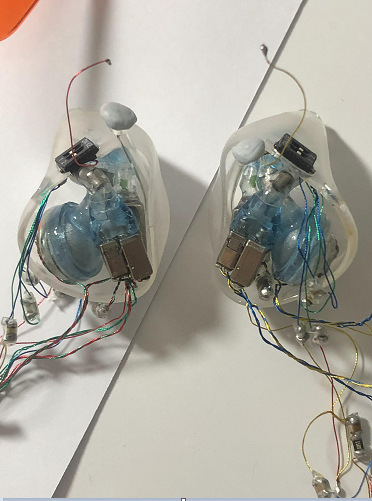

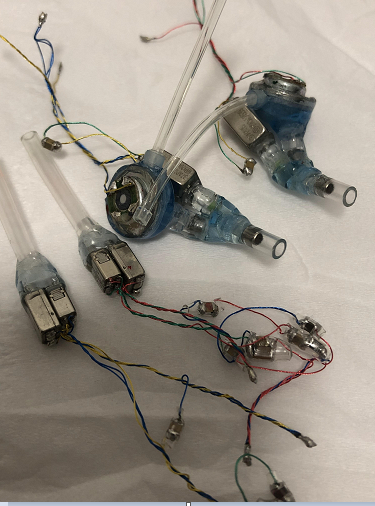

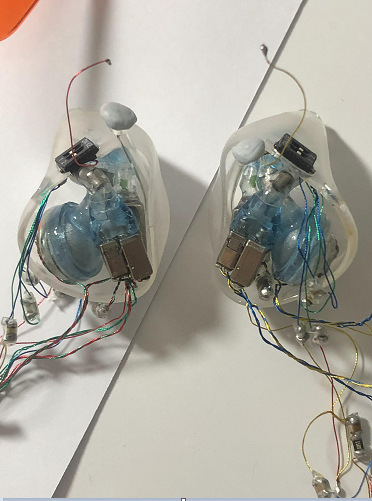

I'm finally completed my 1st hybrid iem, it's lasted almost 10 months. My config is tusq 10mm DD / sonion 37ap015 / sonion 2389 / knowles 31736. Two bores can change damper, 10mm DD have front and back vent, 2 dips switch selector with 4 pre-set sound signature. All parts including splitted / joint tubes, face plate, shells are printed by 3D printer. I used Nova high transparency clear UV resin ----> it is really difficult to use for a beginner like me. I have asked Nova supports for help, but come out is still need to try by yourself.

The Nova HTC UV resin needs a longer exposure time but then the printed model become bigger and it needs to resize the model again and again to print out the correct size.

I have made 3 sets for the same setup, 1 for my uncle and 1 for my nice, but sadly they all moved to UK already, B4 we are neighbour. I have to courier it to them.

The Nova HTC UV resin needs a longer exposure time but then the printed model become bigger and it needs to resize the model again and again to print out the correct size.

I have made 3 sets for the same setup, 1 for my uncle and 1 for my nice, but sadly they all moved to UK already, B4 we are neighbour. I have to courier it to them.

Make sure the front is not connected in any way to the backBy separating venting chambers, what do you mean?

Is connecting only a parallel capacitor to the driver work as low pass filter properly?

Is connecting only a parallel capacitor to the driver work as low pass filter properly?

It will low pass all other drivers in parallel unless you add more components to the circuit

stegeoc

100+ Head-Fier

This venting business is quite interesting and allows far greater tuning options than I’d imagined. I had a half-built hybrid lying around that I couldn’t previously tune properly and front-venting seems to have solved that problem. What I found remarkable was that by adjusting the size of the front-vent between the size of a pin prick and completely blocked varied the bass from no bass at all to far too much bass. Everything in between is possible so long as you have the patience to keep experimenting.

Closing the shell drops the bass again (but not completely) which comes back with a small back-vent. This was with a shell that had very little air in it, so with a more open shell I guess there could be less of an impact of the back-vent.

I’ve only build one side so far so not sure how it sounds, but the FR looks promising (if I can replicate it on the other side). Thanks for all the tips!

One afterthought about separating the vent chambers - does that lead to a more secure fit? Do through-vented iems tend to come loose as there is no air seal? Mine are customs so I hope they will be ok but I'd be more concerned with universals

Closing the shell drops the bass again (but not completely) which comes back with a small back-vent. This was with a shell that had very little air in it, so with a more open shell I guess there could be less of an impact of the back-vent.

I’ve only build one side so far so not sure how it sounds, but the FR looks promising (if I can replicate it on the other side). Thanks for all the tips!

One afterthought about separating the vent chambers - does that lead to a more secure fit? Do through-vented iems tend to come loose as there is no air seal? Mine are customs so I hope they will be ok but I'd be more concerned with universals

Last edited:

stegeoc

100+ Head-Fier

Wow.. That looks amazing. I have no idea how you squeezed all that in so neatly. One question - you put a damper on the back-vent. Is that just to stop stuff getting in there or does it affect the sound?I'm finally completed my 1st hybrid iem, it's lasted almost 10 months. My config is tusq 10mm DD / sonion 37ap015 / sonion 2389 / knowles 31736. Two bores can change damper, 10mm DD have front and back vent, 2 dips switch selector with 4 pre-set sound signature. All parts including splitted / joint tubes, face plate, shells are printed by 3D printer. I used Nova high transparency clear UV resin ----> it is really difficult to use for a beginner like me. I have asked Nova supports for help, but come out is still need to try by yourself.

The Nova HTC UV resin needs a longer exposure time but then the printed model become bigger and it needs to resize the model again and again to print out the correct size.

I have made 3 sets for the same setup, 1 for my uncle and 1 for my nice, but sadly they all moved to UK already, B4 we are neighbour. I have to courier it to them.

stegeoc

100+ Head-Fier

My in-progress (vented) hybrid has a simple low-pass using a cap in parallel with the DD and with that in series with the rest of the circuit (that also has a resistor in parallel with it to tune the mix).Is connecting only a parallel capacitor to the driver work as low pass filter properly?

As the frequency rises the cap reduces in impedance so the DD is bypassed/shorted and most of the signal is sent to the rest of the circuit. So as well as being a low pass on the DD, it is also a treble boost for the rest of the circuit.

I can't find the posts right now, but it has been discussed in this thread. The most natural way of combining drivers is to add them in parallel though, and when you do that you'll need a resistor in series with your low-passed driver or it will low pass the other drivers as @Wgibson said

slakoth453

100+ Head-Fier

I haven't found fit to be a problem, lots of commercial IEMs are vented. If you add an internal front vent but no rear vent that will help with driver flex (and tuning like you said) but you do get very uncomforable pressure build up. This is less of an issue with CIEMs but for universals using silicone tips you always want some sort of pressure relief if you ask me.This venting business is quite interesting and allows far greater tuning options than I’d imagined. I had a half-built hybrid lying around that I couldn’t previously tune properly and front-venting seems to have solved that problem. What I found remarkable was that by adjusting the size of the front-vent between the size of a pin prick and completely blocked varied the bass from no bass at all to far too much bass. Everything in between is possible so long as you have the patience to keep experimenting.

Closing the shell drops the bass again (but not completely) which comes back with a small back-vent. This was with a shell that had very little air in it, so with a more open shell I guess there could be less of an impact of the back-vent.

I’ve only build one side so far so not sure how it sounds, but the FR looks promising (if I can replicate it on the other side). Thanks for all the tips!

One afterthought about separating the vent chambers - does that lead to a more secure fit? Do through-vented iems tend to come loose as there is no air seal? Mine are customs so I hope they will be ok but I'd be more concerned with universals

dhruvmeena96

Headphoneus Supremus

As big of dd you can comfortably put in and as good of a lowpass you can do.... Depends on implementation and better acoustic impedance of large surface areaI'm just getting interested in building some IEMs. Really looking forward to it as i keep not quite finding what i want in the market. Namely very small shells and high technicalities. Which leads me to >

Has anyone tried these planar drivers?

https://www.aliexpress.com/item/100...d716690140637064700e326a!12000017391039314!sh

Also is there a FAQ or getting started guide around?

Lastly any suggestions for DD drivers? I know i can find info on configurations for knowles and sonion ba's but the amount of DDs available on Ali is quite overwhelming. Asking on DD's as i have an old pair of Oriveti New Primacys with a failed DD driver and i might start by replacing the dd's in that set.

CNT, and weird diaphragm type only show advantage in uppermid and high high frequency. And the choice for specific DD diaphragm is used so that a simple crossover can be added without any resonance occuring in uppermid

HahahahahahhahaWow nice! I'm a big fan of eAudio drivers

Noicely done my brotherNot sure about exact tube lengths because I haven't figured out how to measure splines in fusion. The ED (DEG) has a green damper at the nozzle and the SWFK (DWEK) has an orange one at the bend of the tube.

stegeoc

100+ Head-Fier

Does anyone here have a simple answer for how bends in tubes affect the resonant peaks or if they don't? I thought that it didn't matter too much as long as it was smooth, but now I'm not sure.

The purple tube below is my right iem, which worked ok, but the gold tube is the same tube from the left iem (overlaid on the right one for comparison). There are some slight differences in the tube bends (sharper turns) but the lengths are the same. That left iem has a significant dip at about 3kz and doesn't really match the right. Could the problem be the tube shape? Or is the problem likely to be elsewhere? I'm worried I'll destroy the driver if I move it to a reprinted shell so don't want to do that unless there's a good chance it will help. Thanks!

The purple tube below is my right iem, which worked ok, but the gold tube is the same tube from the left iem (overlaid on the right one for comparison). There are some slight differences in the tube bends (sharper turns) but the lengths are the same. That left iem has a significant dip at about 3kz and doesn't really match the right. Could the problem be the tube shape? Or is the problem likely to be elsewhere? I'm worried I'll destroy the driver if I move it to a reprinted shell so don't want to do that unless there's a good chance it will help. Thanks!

Fat Larry

500+ Head-Fier

As big of dd you can comfortably put in and as good of a lowpass you can do.... Depends on implementation and better acoustic impedance of large surface area

CNT, and weird diaphragm type only show advantage in uppermid and high high frequency. And the choice for specific DD diaphragm is used so that a simple crossover can be added without any resonance occuring in uppermid

Hahahahahahhaha

Noicely done my brother

CNT DDs are the best available to the public at the moment?

Hello!

I'm new here, new to ciem and about to make orders for all I need.

I want to do the ciem for stage use for me and my bandmates (Rock. guitar, keys, drums, bass, vocals). Until now we use universal iem (Shure SE535).

The goal is to make comfortable replacements that can sonically keep up with those universal ones. Of course taste differs, but i am talking about the "league" they are playing in. They don't need to sound identically to the SE535.

For beeing new to ciem, I want to start with GV-32830. As this seems relatively easy and they should fit my needs.

I read a lot about ciem the last weeks but surely not all. So now i got a few questions left and hope to find some answers here:

1. Wax for dipping the impressions: Should I prefer Dreve dipping wax (https://otoplastikshop.dreve.de/otoplastiken/paraffin-dipping-wax-4287.html) or these plates: https://otoplastikshop.dreve.de/otoplastikde/modellierwachs-4296.html ?

2. vents: do you prefer to leave the vents open or closed?

3. tubes: at the moment im planing with 1.0x2.0 tubes at the ends and in between 2.0x3.0 tubes with the dampers. same on tweeter and woofer. because I saw someone doing it this way. is this a common method?

4. wire to connect driver with socket: do you recommend this type: https://bit.ly/3VvvUVP or this one: https://bit.ly/3B8fvyu ?

5. colors: I will use Dreve Fotoplast S IO transparent. Do I need some special colors or can I use simple resin colors like this: https://bit.ly/3VvwUt3 ?

6. flakes: any recomendation for flakes to mix with the Fotoplast? Or is this a bad idea because the Fotoplast might not cure everywhere because the flakes don't let uv light through?

Thank you all for all the information shared in this awesome thread!

I'm new here, new to ciem and about to make orders for all I need.

I want to do the ciem for stage use for me and my bandmates (Rock. guitar, keys, drums, bass, vocals). Until now we use universal iem (Shure SE535).

The goal is to make comfortable replacements that can sonically keep up with those universal ones. Of course taste differs, but i am talking about the "league" they are playing in. They don't need to sound identically to the SE535.

For beeing new to ciem, I want to start with GV-32830. As this seems relatively easy and they should fit my needs.

I read a lot about ciem the last weeks but surely not all. So now i got a few questions left and hope to find some answers here:

1. Wax for dipping the impressions: Should I prefer Dreve dipping wax (https://otoplastikshop.dreve.de/otoplastiken/paraffin-dipping-wax-4287.html) or these plates: https://otoplastikshop.dreve.de/otoplastikde/modellierwachs-4296.html ?

2. vents: do you prefer to leave the vents open or closed?

3. tubes: at the moment im planing with 1.0x2.0 tubes at the ends and in between 2.0x3.0 tubes with the dampers. same on tweeter and woofer. because I saw someone doing it this way. is this a common method?

4. wire to connect driver with socket: do you recommend this type: https://bit.ly/3VvvUVP or this one: https://bit.ly/3B8fvyu ?

5. colors: I will use Dreve Fotoplast S IO transparent. Do I need some special colors or can I use simple resin colors like this: https://bit.ly/3VvwUt3 ?

6. flakes: any recomendation for flakes to mix with the Fotoplast? Or is this a bad idea because the Fotoplast might not cure everywhere because the flakes don't let uv light through?

Thank you all for all the information shared in this awesome thread!

stegeoc

100+ Head-Fier

Good luck, GV sounds great and is easy to use. I'll have a go at answering these but I'm still a beginner so others will know better.Hello!

I'm new here, new to ciem and about to make orders for all I need.

I want to do the ciem for stage use for me and my bandmates (Rock. guitar, keys, drums, bass, vocals). Until now we use universal iem (Shure SE535).

The goal is to make comfortable replacements that can sonically keep up with those universal ones. Of course taste differs, but i am talking about the "league" they are playing in. They don't need to sound identically to the SE535.

For beeing new to ciem, I want to start with GV-32830. As this seems relatively easy and they should fit my needs.

I read a lot about ciem the last weeks but surely not all. So now i got a few questions left and hope to find some answers here:

1. Wax for dipping the impressions: Should I prefer Dreve dipping wax (https://otoplastikshop.dreve.de/otoplastiken/paraffin-dipping-wax-4287.html) or these plates: https://otoplastikshop.dreve.de/otoplastikde/modellierwachs-4296.html ?

2. vents: do you prefer to leave the vents open or closed?

3. tubes: at the moment im planing with 1.0x2.0 tubes at the ends and in between 2.0x3.0 tubes with the dampers. same on tweeter and woofer. because I saw someone doing it this way. is this a common method?

4. wire to connect driver with socket: do you recommend this type: https://bit.ly/3VvvUVP or this one: https://bit.ly/3B8fvyu ?

5. colors: I will use Dreve Fotoplast S IO transparent. Do I need some special colors or can I use simple resin colors like this: https://bit.ly/3VvwUt3 ?

6. flakes: any recomendation for flakes to mix with the Fotoplast? Or is this a bad idea because the Fotoplast might not cure everywhere because the flakes don't let uv light through?

Thank you all for all the information shared in this awesome thread!

1. I just used cheap local paraffin wax, I can't imagine it makes a huge difference. You'll be sanding it down later anyway.

2. I had 2 open and 2 closed I think. You can measure/listen and adjust to taste before you close it up

3. I used 2mm ID tubes. I would imagine you'd lose some treble if you used 1mm ID tubing for the tweeter. Maybe that is desirable to some. With 2mm ID tubing all the way you'll have more options for damper placement

4. I don't think wires will make much difference, if you're going to be able to see them then take that into account

5. I had no problem using normal resin dyes. Of course exposure times will vary so you'll need to experiment.

6. Not tried flakes but added some black mica for one pair. Don't recall having any problems with exposing it and the specs do hide any imperfections/bubbles quite well as a bonus. I'd say you should be fine with flakes, unless you go over the top

Users who are viewing this thread

Total: 17 (members: 1, guests: 16)