3ggerhappy

100+ Head-Fier

- Joined

- Oct 1, 2015

- Posts

- 205

- Likes

- 676

Other way around - exactly in reverse to your pic

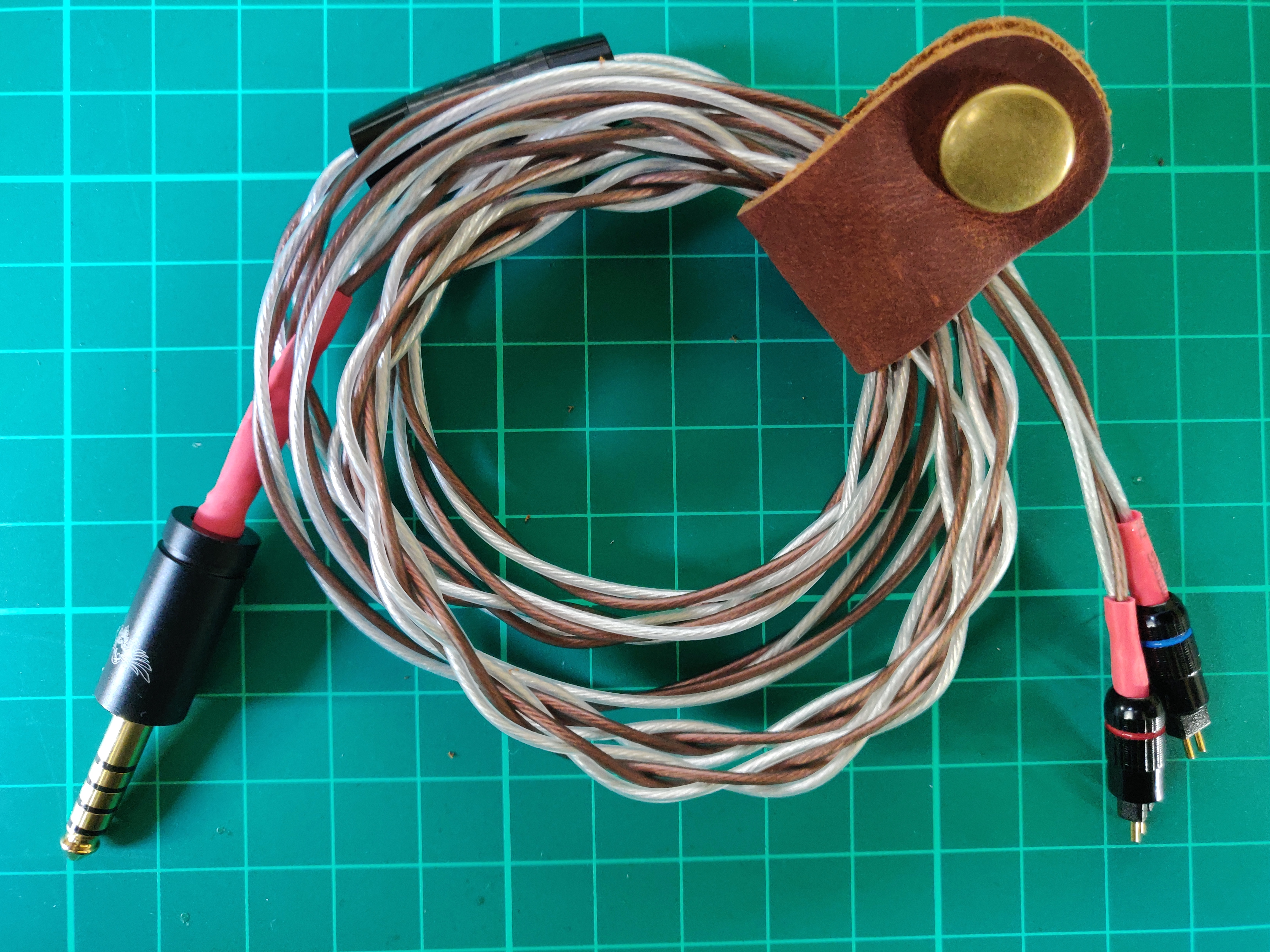

Dang, Thanks for the confirmation, first time doing this and I got it wrong the first time.

Other way around - exactly in reverse to your pic

Dang, Thanks for the confirmation, first time doing this and I got it wrong the first time.

FYI, a decent DMM can be had for quite cheap and makes it easy to verify these sort of things.

Yeah, ordered one actually but its taking its time to arrive due to the covid situation. Also do not know how to properly use it still(except maybe basic continuity feature) I'll go experiment when it arrives.

Until it arrives, it's worth sharing that every standard connector I've used so far (2.5mm/3.5mm/4.4mm) has always worked back to front - so the tip of the connector is usually the smallest part of the soldering end (and the furthest away from the tip) and works its way back. Make sense? If not I'll try and draw a rough diagram for what I mean

so this is probably a real dumb question. I did look through all the gallery images to see if I could make this out from someone's pic but no luck. The eidolic connectors I have (2.5mm TRRS and 3.5mm TRS) seem to just be hollow barrels on the "wire" side. What do you guys do to plug that hole up? They came with some rubber plug looking things but they dont really fit all that great.

Do you just melt hot glue into there? or some form of epoxy? Or is there some specific way to use heat shrink tubing?

Same question goes for the cable splitter, its a hollow tube with one end wide open and the other end having a 2-hole sort of design, which I assume is for splitting the wire off between left/right sides.

how do you guys provide strain relief? or is the glue/heat shink enough to strain relief?

Still hoping someone in this thread has used the eidolic connectors.

no glue/epoxy inside the connector?I use Eidolic connectors and just used some heatshrink over the connections inside the connector and left it long enough that it protrudes from inside the connector a bit for strain relief.

no glue/epoxy inside the connector?