@tib8

The )( shape is important for me for 2 reasons - 1st to make the stator sturdy, so it does not vibrate on electrostatic forces. (for my normal designs I use double sided 1mm FR4. 2-nd to "follow" the shape of the membranes (when +-360V is applied to them they bend against each other. With a flat stator the center of the membranes is closer to the stator. By the way, this also applies to the classic 2 stator design, because membrane is always attracted more to one of the stators. The option of ordering PCB is good, I have considered it many times, but this is going to be a pretty complicated board. And before I do that, I want to check if it's worth it

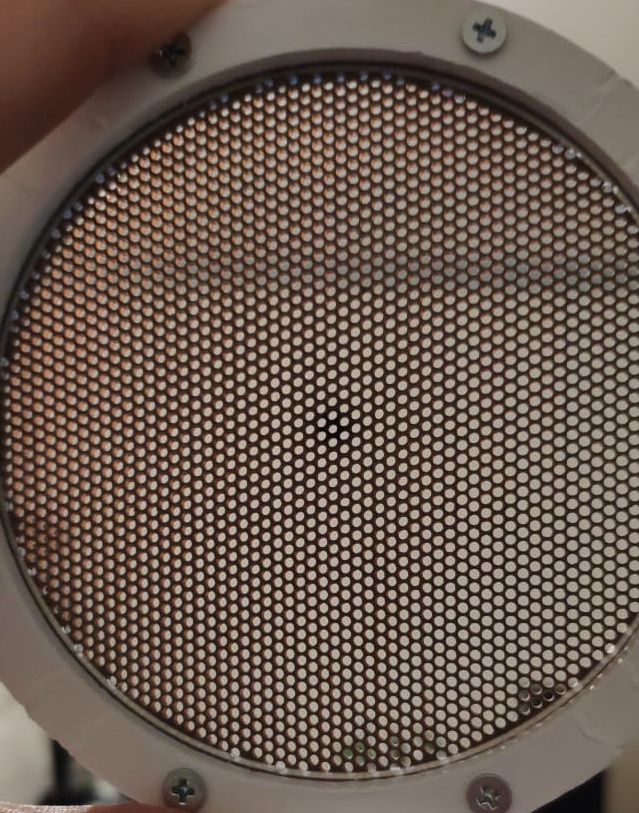

- for CNC this is pretty simple job. I made already 4 FR4 0.6 mm stators for about 1 hour including the about 2000 holes.

Soldering in the middle is a bit of a challenge, I need to solder inside a 1mm hole a thin layer (35um) of copper.

Unfortunately I can't give you advise on improvement of the stretching, because I use the same wet "glass table" method. I stretch the membrane with a microfiber cloth to remove any wrinkles. Then as you do I just drop the frames and press for about half an hour with something flat and heavy. Your results are quite similar to what I measure with mine - about 140-160 Hz, +-360V and 0.6mm spacing. If I go higher they become unstable. Still I got pretty good bass measured down to 10-15 Hz. Once I got 5Hz, but with a DC amp (no decoupling capacitors) and membranes were unstable. By the way I measured many times the FR response and I think tension does not affect the bass so much as the sealing of the earpads.

Since I do this stretching once in a year or when I make a new model, I don't have much data to share. I believe tire jig is the answer, I just have to make one and do some experiments with different tensions and measurements. But the frames I have are only the ones I use in the phones and I'm too lazy to cut many of them to compare.

The sound level is also good for my taste, but it's far from a dynamic headphones. So if I want to listen very loud, the amp starts clipping.

- for CNC this is pretty simple job. I made already 4 FR4 0.6 mm stators for about 1 hour including the about 2000 holes.

- for CNC this is pretty simple job. I made already 4 FR4 0.6 mm stators for about 1 hour including the about 2000 holes.