Next time try double side duct tape. It's a bit tricky to cut thin parts but it's easier for testing and tuningAll of the shells that I ordered (except the yuin) were smaller than the driver so I have to glue them in. That make tuning them a hassle because I have to wait half a day for the glue to cure and if I don't like the sound I have to pry the driver out again.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Earbuds

- Thread starter gwompki

- Start date

I've been thinking about trying polymer clay for shellsAlot of DIY people do their own shells, I even saw someone use a full brass MX500-like shell, pretty insane. Someone also used clay to sculpt a custom shell

Themilkman46290

1000+ Head-Fier

Careful, I tried a little while back with white abs plastic (had a half liter left over from some side work) results looked cool, making a mold was fairly easy, but my wife had a weird skin reaction and got a rash where the plastic touched, I ended up tossing them out.I've been thinking about trying polymer clay for shells

I am sure it can be done, with most materials, clays, plastics, polymers but it maybe needs some skin safe coating

Last edited:

Yup. I think that Polymer clay after bake is safe for skin. Also, UV resin as coat finish produces a very cool effect. Jewelry made this way really looks amazingCareful, I tried a little while back with white abs plastic (had a half liter left over from some side work) results looked cool, making a mold was fairly easy, but my wife had a weird skin reaction and got a rash where the plastic touched, I ended up tossing them out.

I am sure it can be done, with most materials, clays, plastics, polymers but it maybe needs some skin safe coating

Last edited:

purplesun

1000+ Head-Fier

- Joined

- Aug 17, 2004

- Posts

- 1,046

- Likes

- 975

On the subject of earbud glue, I use 3M micropore surgical tape (1cm size) in replacement of glue. Came up with the idea as I got fed up messing around with glue while prototyping and testing. I liked it so much, it became a permanent feature of the earbuds that I close up. Cut about 4 cm long and 5mm wide - that should be wide and long enough to hold the shells together while being able to hide under the earbud foam when installed. IMO, it's easier, less mistakes and more uniform pressure seal with tape rather than glue.

.

.

Last edited:

assassin10000

Headphoneus Supremus

On the subject of earbud glue, I use 3M micropore surgical tape (1cm size) in replacement of glue. Came up with the idea as I got fed up messing around with glue while prototyping and testing. I liked it so much, it became a permanent feature of the earbuds that I close up. Cut about 4 cm long and 5mm wide - that should be wide and long enough to hold the shells together while being able to hide under the earbud foam when installed. IMO, it's easier, less mistakes and more uniform pressure seal with tape rather than glue.

.

While I would do that as a temporary measure, as the micropore tape ages the adhesive becomes worse to deal with. Not the greatest to deal with if you feel like doing anything else after a couple months, due to the residue.

Still, a really good way to do tuning.

Themilkman46290

1000+ Head-Fier

The cloth medical tape works much better, 3m loses its grip after 1 sweaty day, Leaving us with that stickiness, the cloth bandage tape has held my daily driver earbud for 2 months with heavy use (while working, sanding, polishing and getting very sweaty) and it doesn't crease or wrinkle like the 3m tape.On the subject of earbud glue, I use 3M micropore surgical tape (1cm size) in replacement of glue. Came up with the idea as I got fed up messing around with glue while prototyping and testing. I liked it so much, it became a permanent feature of the earbuds that I close up. Cut about 4 cm long and 5mm wide - that should be wide and long enough to hold the shells together while being able to hide under the earbud foam when installed. IMO, it's easier, less mistakes and more uniform pressure seal with tape rather than glue.

.

purplesun

1000+ Head-Fier

- Joined

- Aug 17, 2004

- Posts

- 1,046

- Likes

- 975

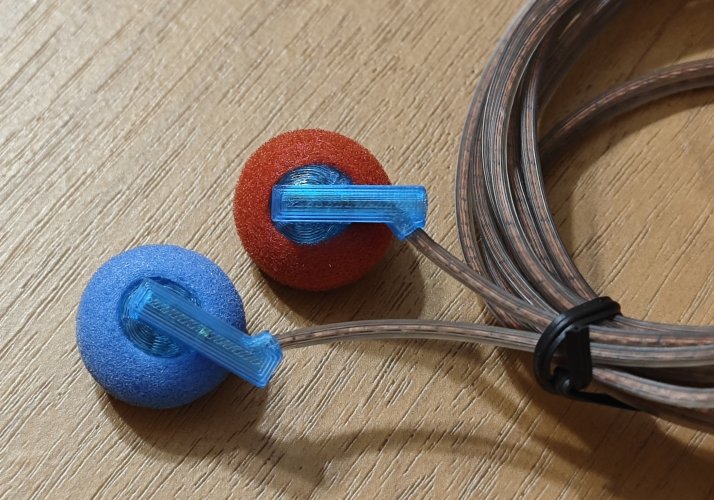

Yeah, a lot less stressful with the tape opening, closing, opening, closing, opening, closing... the shells when trying to get the sound right  . It gets "gummy" after 6 to 9 months of constant use, but that's when the ear foams also needs replacing - so I change the tape at the same time. The one in the pic was installed about Dec '19, but I have only used it constantly for about 1 month.

. It gets "gummy" after 6 to 9 months of constant use, but that's when the ear foams also needs replacing - so I change the tape at the same time. The one in the pic was installed about Dec '19, but I have only used it constantly for about 1 month.

. It gets "gummy" after 6 to 9 months of constant use, but that's when the ear foams also needs replacing - so I change the tape at the same time. The one in the pic was installed about Dec '19, but I have only used it constantly for about 1 month.

. It gets "gummy" after 6 to 9 months of constant use, but that's when the ear foams also needs replacing - so I change the tape at the same time. The one in the pic was installed about Dec '19, but I have only used it constantly for about 1 month.

Last edited:

KevDzn

100+ Head-Fier

- Joined

- Jan 23, 2017

- Posts

- 137

- Likes

- 211

I've been using "B-7000 Multi Purpose Glue" for my diy earbuds. It's actually used to seal mobile phones screen or the the back panel. If you apply heat to it you can unglue it without damage. Its something of a rubber sealant, very easy to apply and remove.

I ordered E8000 glue personally, not sure what's the difference between this and b7000, maybe the viscosity. I hope it will arrive soon and without any hole on the tube lol.  Maybe I'll try this tape fixing technique, but sadly the medical tapes I have at home leave very sticky residue instantly

Maybe I'll try this tape fixing technique, but sadly the medical tapes I have at home leave very sticky residue instantly

By the way I did a quick build few weeks ago, with the N50 speakers (I removed the stock foam so they're bare) and regular black mx500 shells plus their horseshoe. Snap is quite strong, doesn't even rotate so it works well without glue. The sound signature is surprisingly v-shaped but with a smooth gentle treatment, so it never sounds too sharp or bright. The tuning and the characteristics of the speaker balance out each other quite nicely. (N50 speaker by itself is smooth and slightly midcentric) I generally prefer a flatter signature but actually I quite enjoy this sound, punchy and spacious but not fatiguing. Of course the vocals are a bit thin but with an organic quality, not sharp metallic like with emx500 speakers . It's a good improvement over the stock setup, which was a foam installed on the speakers themselves and using the bundled type of mx500. This setup is tighter, cleaner, smoother, deeper. BTW the steel mesh cover + mx500 shell has a more stable fit for me compared to the plastic cover, maybe even suitable for walking around, I'll test it.

By the way I did a quick build few weeks ago, with the N50 speakers (I removed the stock foam so they're bare) and regular black mx500 shells plus their horseshoe. Snap is quite strong, doesn't even rotate so it works well without glue. The sound signature is surprisingly v-shaped but with a smooth gentle treatment, so it never sounds too sharp or bright. The tuning and the characteristics of the speaker balance out each other quite nicely. (N50 speaker by itself is smooth and slightly midcentric) I generally prefer a flatter signature but actually I quite enjoy this sound, punchy and spacious but not fatiguing. Of course the vocals are a bit thin but with an organic quality, not sharp metallic like with emx500 speakers . It's a good improvement over the stock setup, which was a foam installed on the speakers themselves and using the bundled type of mx500. This setup is tighter, cleaner, smoother, deeper. BTW the steel mesh cover + mx500 shell has a more stable fit for me compared to the plastic cover, maybe even suitable for walking around, I'll test it.

Last edited:

When I mentioned the double-side duct tape I meant this. The tape is placed on the inside of the plastic coverOn the subject of earbud glue, I use 3M micropore surgical tape (1cm size) in replacement of glue. Came up with the idea as I got fed up messing around with glue while prototyping and testing. I liked it so much, it became a permanent feature of the earbuds that I close up. Cut about 4 cm long and 5mm wide - that should be wide and long enough to hold the shells together while being able to hide under the earbud foam when installed. IMO, it's easier, less mistakes and more uniform pressure seal with tape rather than glue.

.

BTW... if you are wondering which driver has the best abs, the berillyum 130ohm has 8-pack abs

Last edited:

purplesun

1000+ Head-Fier

- Joined

- Aug 17, 2004

- Posts

- 1,046

- Likes

- 975

Loving the hacking spirit in here! I need more protein shakes

Don't forget to do some crunches and leg rises before modding the earbudsLoving the hacking spirit in here! I need more protein shakes

Haha good one, it's certainly the fittest of all by the looks. By the way, what those LF and HF marks mean? I've always found intriguing why this one has 4 pairs of solder blobs, but I've never looked into it as I don't own oneWhen I mentioned the double-side duct tape I meant this. The tape is placed on the inside of the plastic cover

BTW... if you are wondering which driver has the best abs, the berillyum 130ohm has 8-pack abs

Probably a Chinese way of marking the abdomen. This is 8-pack which is rare in EuropeHaha good one, it's certainly the fittest of all by the looks. By the way, what those LF and HF marks mean? I've always found intriguing why this one has 4 pairs of solder blobs, but I've never looked into it as I don't own one

When we do some crunches middle abs produce low an high frequency. LF and HF in short

Last edited:

Users who are viewing this thread

Total: 5 (members: 0, guests: 5)