I've got one of these ivipQ-65 Pure Silver and Single Crystal Copper cables [ https://www.aliexpress.com/item/1005003688146295.html ] ordered, to replace the cable on my "Blur hALF/hALF", since the black insulation on the stock copper wires is disintegrating where it's in contact with my skin (wearing the cables over-the-ear). The stock cable is 4-Strands (two per earbud), and the new cable is 8-Strands (four per earbud) - so I'll probably have to combine the 4 wires to 2 wires, and reduce the total cross-section, so they'll fit into the shells. I'll also have to cut-back or remove the earhook heat shrink.

in my opinion i think you can pass the wires, and connect all 4 wires, for example:

Last edited:

This is better option than BT which has a range of 10m

This is better option than BT which has a range of 10m

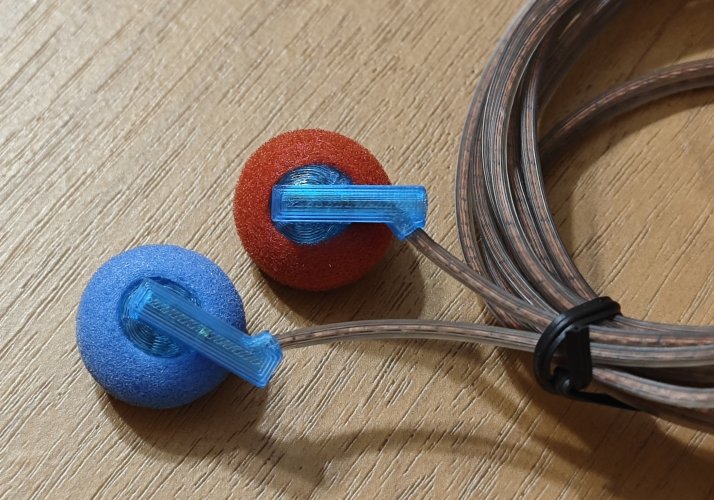

It's a bit short but it looks ok. You can twist the wire, than use shrink tube and eartip ring part over.

It's a bit short but it looks ok. You can twist the wire, than use shrink tube and eartip ring part over.