TheLastAurora

New Head-Fier

Yeah, so...

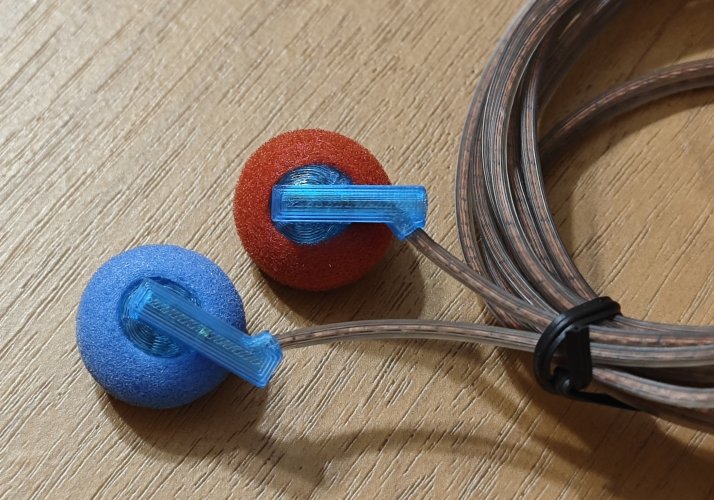

I waited for nearly two months and got a broken LCP driver and a not so good post-buy experience from Chitty store, but that happens - I guess. Not the best way to start a jorney lmao. Today I managed to rip the driver safely. Any ideas on how to repair this? If possible ofc.

I waited for nearly two months and got a broken LCP driver and a not so good post-buy experience from Chitty store, but that happens - I guess. Not the best way to start a jorney lmao. Today I managed to rip the driver safely. Any ideas on how to repair this? If possible ofc.