Xan7hos

1000+ Head-Fier

- Joined

- Dec 9, 2007

- Posts

- 1,156

- Likes

- 14

zk that thing is freakin amazing!

| Originally Posted by MoodySteve /img/forum/go_quote.gif You make me realize how much I have to learn about woodworking.

|

| Originally Posted by oneplustwo /img/forum/go_quote.gif ZK - what are you planning on doing with the top as far as finish? Also, how are you attaching the top to the rest of the case? I'm trying to figure out what to do with the top of mine. |

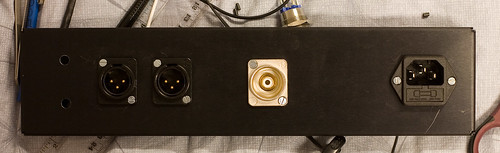

| Originally Posted by danobeavis /img/forum/go_quote.gif Here's a couple of preamp enclosures I'm working on. Wood and finished aluminum from basic stock. |

| Originally Posted by oneplustwo /img/forum/go_quote.gif This thread can't be dying off already! |

| Originally Posted by oneplustwo /img/forum/go_quote.gif Here's some progress against the front panel for a Buffalo32S I'm working on: It's just a piece of birch from HD. Planning on tung oil and polyurethane finish after rounding over the edges. |

| Originally Posted by qusp /img/forum/go_quote.gif awesome work on the Bijou zkool448, what is the model number of that LED switch you used if you dont mind?? and where did you get it?? its little finishes like that thet I would like to use for my B32 build. also do you have any experience getting wood laser-cut?? wondering if there is anything in particular I need to be aware of. of course with your skill its unlikely you have bothered to get any done, but thought I would ask you and the thread. i'm making a mixed media case with diecast, clear acrylic and some Amboyna that I have left over from some denon cups. so I wont be doing the work, but I have designed all the panels in illustrator and cad. does that count??

|

| Originally Posted by suo /img/forum/go_quote.gif zkool that bijou cannot possibly be DIY. Phenomenal work. |