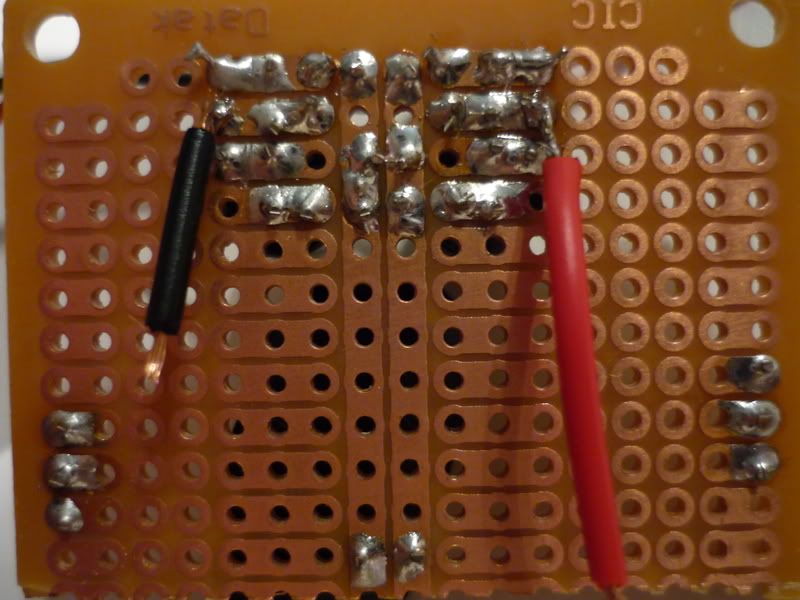

Yep, that is what a solder bridge is, solder touching on both holes, or both legs on a microchip(quite common on small chip legs).

In my experience, the only cause of my projects not to work the first time I switch them on was either a solder bridge or a cold solder joint. So check your work with a magnifying glass for solder bridges, and reflow the solder joints if your project doesn't work the first time.

Also, buy a help hand, the thing that is holding up my mini3, don't start a project without one!

If you haven't soldered before, watched the soldering videos on tangent,

Tangent Tutorials , and perhaps buy a cheap circuit board and some parts, the practice on that. The tangent videos were great, definitely was a solid guideline for me when I tackled the mini3, then onto surface mount soldering on the alien dac.

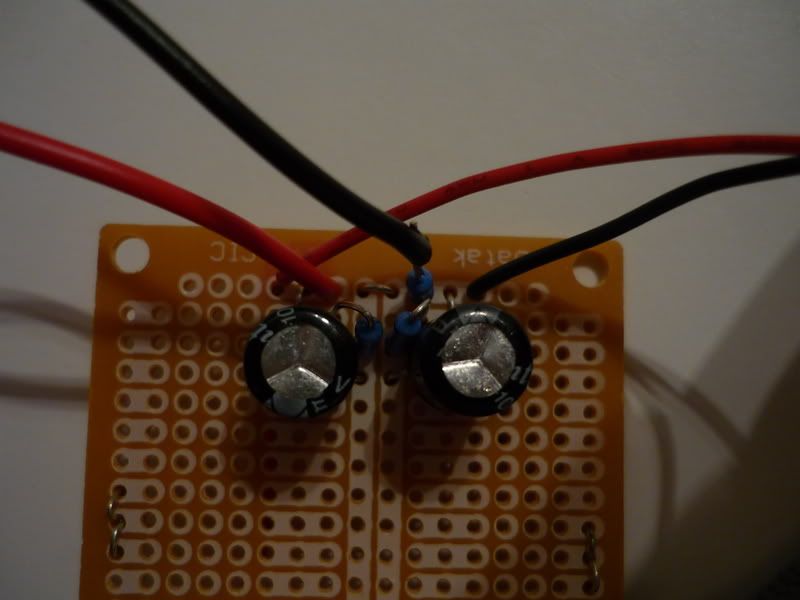

I recently finished a mini3 and an alien dac as my first diy projects. It really wasn't hard, what really helped me were the tangentsoft.com soldering tutorials, and finished pictures of other people's builds, so I can check against their working boards with my own. After you are finished and if it doesn't work, people on here will help you sort through the problem.

These are the tools I used to build the mini3 and the Alien dac, without any one of them I couldn't have finished the projects.

Multimeter- a must for trouble shooting, I would measure the voltages or ohms for set points on the board to check if I get the correct measurement suggested

Solder

Safety glasses- I try to wear these as much as I can, hot stuff with splash around whenever I tin my soldering iron

Desoldering braid(light blue thing with cuppoer braid)- to suck up solder when you need to take a component out, or clean up excess solder

Wire cutters- to cut wires and excess pin from resistors, caps

tweezers- hand small parts and to avoid heat from soldering iron

Helping hands with magnifiying glass- couldn't have done the projects without this

soldering iron with stand and sponge- set your soldering iron in the stand for safety, and always clean your soldering tip with the sponge, pretty much after every solder joint

Soldering paste or flux(the blue tub)- to make a better soldering joint, but I didn't really use it as my solder already has flux in it

Oh and a multimeter is absolutely necessary, you should be able to get a cheap one for around $10 USD. Mine was like $8USD bought here in Hong Kong.

Keyid pretty much hit the spot with the steps.