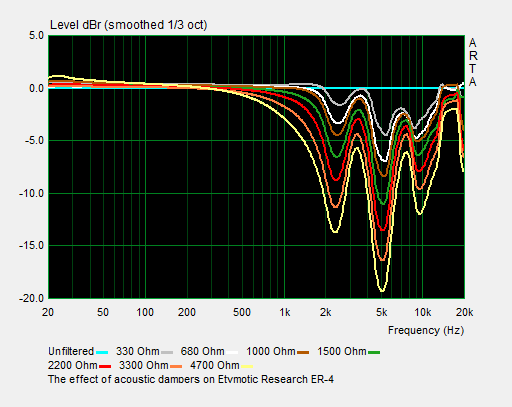

IEC711 is only specified up to 10kHz. So the coupler might measure beyond that but will not be accurate.

Furthermore you shouldn't care to much about what's going on from 10 - 20 kHz, not to mention 20 - 40 kHz.

Furthermore you shouldn't care to much about what's going on from 10 - 20 kHz, not to mention 20 - 40 kHz.