As long as the BT chipset supports aptx Adaptive and the smartphone supports QHS (Qualcomm High Speed link, which technically all flagship Snapdragon SoC, 888 and beyond, should have), you will get aptx Lossless - which basically means aptx Adaptive running on 24/96 transmission rate. Normal aptx Adaptive only runs on 24/48.Thank you very much for your reply! I wonder if this chipset supports the new aptx lossless format, which may be updated in the future

Latest Thread Images

Featured Sponsor Listings

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ClieOS's Random DIY Build Thread - [Updated: Mar.17th, 25] - iBasso CB19 Type C-to-C cable Mod

- Thread starter ClieOS

- Start date

Ahhh, well understood. Thanks for the explanationAs long as the BT chipset supports aptx Adaptive and the smartphone supports QHS (Qualcomm High Speed link, which technically all flagship Snapdragon SoC, 888 and beyond, should have), you will get aptx Lossless - which basically means aptx Adaptive running on 24/96 transmission rate. Normal aptx Adaptive only runs on 24/48.

Sony MDR-E282 reproduction shell Kit Build

This kit is made by the same Chinese DIYer that offers the V55 kit which I have previously built. E282 is really one of the first generations of high-end earbuds of its time, featuring 16mm drivers (*the other common size of its time is 13.5mm). Technically this is a simpler build than the V55 kit, the issue is mainly that E282 has a rather shallow magnet (which is fairly typical of its era) and thus you can't just simply use any 16mm driver as the back end will likely not fit inside the metal shell. My conclusion is that, if you want to build this kit, it is better to keep to the 16mm drivers from MDR-E2xx and MDR-4xx series. Anything newer might not fit. As part of this rebuild, I actually spent almost 2 months scouting various auction sites to hunt for suitable drivers. Besides eBay, the best place I found is the Yahoo Japan Auction site. For those living outside of Japan or can't read Japanese, you can use Buyee.jp for its betting, buying, and forwarding services. Below are some extra info regarding all major Sony earbuds generation:

MDR-E1xx series: mono earbud, pre-early 80s, mostly for portable FM radio which hadn't really offered any stereo sound yet.

MDR-E2xx series: E262, E272, and E282 as top-end models, featuring sapphire or diamond-plated diaphragm

MDR-E4xx series: E464 and E484 as the top-end models with the latter often being considered to be the best earbuds Sony ever made.

MDR-E5xx series: E565 and E575 as the top-end models

MDR-E7xx series: E737 and E747 as the top-end models

MDR-E8xx series: E868 and E888 as the top-end models

Anything beyond E8xx series is not worth bothering, including the E9xx and E0xxx series

For the most part, I won't recommend getting E282 or E484 for the DIY project unless you already have a pair at hand, as they are extremely rare and astronomically expensive. For the demonstration below, I am using a pair of E262 drivers that I got from the Japan Yahoo auction site. It was about US$130 with all the associated Buyee fees, including international shipping. A typical good condition E262 will likely cost close to, if not over US$200. I got it cheap because the pair I got is labeled as 'junk' or not working. I took a chance and it turned out to be just a cable issue (the original cable had cracked, which is common for old earbuds). Given the ideal is to reshell the earbud with new cable anyway, it would be logical to hunt for cheaper, less-than-ideal condition earbuds for the project rather than those in good condition that have a high price tag. However do note that anything labeled as 'junk' could literally just be junk and you might not get any good driver out of it, as in the nature of any auction. If you don't really want to spend more than $100 for the drivers, go and look for E472 instead. E472 is often referred to as the lesser-sounding, cheaper but still really good alternative of E484. It had been extensively used by Sony as the stock earbud for its higher-end cassette Walkman models and thus it is easier and cheaper to find (with a good working pair often just under $100). Some reports from the Chinese DIY community have even suggested that reshelled E472 can almost rival that of reshelled E484.

Last but not least, the E282 DIY kit is not cheap. It comes in two main versions: Silver alloy is around $150 and copper alloy is around $107. They also have various outer color finishes. Both versions are of great quality and it is almost impossible to tell apart.

Tools and parts needed:

1) E282 shell DIY kit, can only be found on Taobao.

2) A pair of 16mm Sony drivers, either from the E2xx or E4xx series.

3) Old school cable with 1.5mm OD wire.

4) Super glue, the best you can get. I used Ergo by Kisling Switzerland

5) Headphone glue, i.e. G-S Hypo Cement, E7000, or anything similar

6) Soldering supply

7) Optional: UV solder mask.

The above is all the E282 kit comes with (from top left): tail caps, rubber tubes cut to pointy end, old-school cable Y-splitter, the main shells (with strain relief already inserted), rubber rings for securing the drivers., dampening foam pads, metal grill and driver mounts. Note that you don't need to use the metal grill if your driver still has its original metal grill. But if you do want to use the metal grill, you might need to find some metal mash for the front and tuning paper at the back, depending on how you like to tune the drivers. This particular kit above is copper with rose gold finish.

Here is the original E262 I got from Japan and the old-school cable I got from an old Cresyn earbud. The cable must be thin enough so it will go through the strain relief of the replacement shell.

Note that these kind of old-school cables usually has color-coded plastic insulated wires inside (red for right, green for left, and copper for ground). You will need to expose around 25~30mm of the cable as shown in the picture above.

Take the strain relief out of the metal housing and slide it onto the cable. Put the super glue on the area marked in red, then slide the strain relief up slowly till only the exposed wire is left hanging out. Take note that you will NOT be able to adjust the cable from this point forward, so you will want more than enough exposed wires than just enough as it will be much easier to cut away any excess.

Wait till the super glue is dried completely, then insert the strain relief and wires into the housing. Again, make sure enough wire is left so soldering will be easier. Now put some normal glue to the metal housing and glue the dampening foam in place, as marked by the white arrows.

Now compress the rubber pointy tube slightly and insert it into the socket / groove of the metal shell. Push it down toward the strain relief as much as you can, though it will not fit completely inside by design. The pointy end will curve up and that's normal. Just be sure that the rubber tube will still form an open vent to redirect air downward.

Now prepare the wire by burning off the plastic coating using the soldering iron, then solder the driver in as shown by the picture and arrows. This is done to minimize any of the wires shorting with the metal housing as the housing themselves are highly conductive (the original housing is plastic and doesn't have this issue). I will highly recommend you to apply some UV soldering mask to both the soldering joint as well as the wires just to add an extra layer of safety.

Adjust the driver mount (*white arrow) so it will sit tightly with the driver, then insert the driver into the metal shell while making sure the soldering joint will be parallel to the shell's socket (*red marking)

Put on the rubber ring to secure the driver and insert the tail cap to secure the strain relief. Enjoy.

------------------------------------

Below is another reshelling using MDR-A22 driver with silver metal shell with gold finish. A22 is around the same timeframe as E484 and was said to have the same driver as E484. It is also extremely rare and I got very lucky as it was included in a bundle sale with a Walkman.

Afterthought: This is overall an easy but expensive build, with a very satisfying result nonetheless. In the end, I have two really unique and great-sounding earbuds out of the built, even though it certainly took me quite some effort. Last but not least - if you are looking for great-sounding earbuds, you can probably find modern, still-in-production earbuds that are better than these reshelled Sony with equal if not better value. While I still consider what I have built to be excellent, this project also has a lot to do with nostalgic as well as preservative reasons rather than purely about SQ.

This kit is made by the same Chinese DIYer that offers the V55 kit which I have previously built. E282 is really one of the first generations of high-end earbuds of its time, featuring 16mm drivers (*the other common size of its time is 13.5mm). Technically this is a simpler build than the V55 kit, the issue is mainly that E282 has a rather shallow magnet (which is fairly typical of its era) and thus you can't just simply use any 16mm driver as the back end will likely not fit inside the metal shell. My conclusion is that, if you want to build this kit, it is better to keep to the 16mm drivers from MDR-E2xx and MDR-4xx series. Anything newer might not fit. As part of this rebuild, I actually spent almost 2 months scouting various auction sites to hunt for suitable drivers. Besides eBay, the best place I found is the Yahoo Japan Auction site. For those living outside of Japan or can't read Japanese, you can use Buyee.jp for its betting, buying, and forwarding services. Below are some extra info regarding all major Sony earbuds generation:

MDR-E1xx series: mono earbud, pre-early 80s, mostly for portable FM radio which hadn't really offered any stereo sound yet.

MDR-E2xx series: E262, E272, and E282 as top-end models, featuring sapphire or diamond-plated diaphragm

MDR-E4xx series: E464 and E484 as the top-end models with the latter often being considered to be the best earbuds Sony ever made.

MDR-E5xx series: E565 and E575 as the top-end models

MDR-E7xx series: E737 and E747 as the top-end models

MDR-E8xx series: E868 and E888 as the top-end models

Anything beyond E8xx series is not worth bothering, including the E9xx and E0xxx series

For the most part, I won't recommend getting E282 or E484 for the DIY project unless you already have a pair at hand, as they are extremely rare and astronomically expensive. For the demonstration below, I am using a pair of E262 drivers that I got from the Japan Yahoo auction site. It was about US$130 with all the associated Buyee fees, including international shipping. A typical good condition E262 will likely cost close to, if not over US$200. I got it cheap because the pair I got is labeled as 'junk' or not working. I took a chance and it turned out to be just a cable issue (the original cable had cracked, which is common for old earbuds). Given the ideal is to reshell the earbud with new cable anyway, it would be logical to hunt for cheaper, less-than-ideal condition earbuds for the project rather than those in good condition that have a high price tag. However do note that anything labeled as 'junk' could literally just be junk and you might not get any good driver out of it, as in the nature of any auction. If you don't really want to spend more than $100 for the drivers, go and look for E472 instead. E472 is often referred to as the lesser-sounding, cheaper but still really good alternative of E484. It had been extensively used by Sony as the stock earbud for its higher-end cassette Walkman models and thus it is easier and cheaper to find (with a good working pair often just under $100). Some reports from the Chinese DIY community have even suggested that reshelled E472 can almost rival that of reshelled E484.

Last but not least, the E282 DIY kit is not cheap. It comes in two main versions: Silver alloy is around $150 and copper alloy is around $107. They also have various outer color finishes. Both versions are of great quality and it is almost impossible to tell apart.

Tools and parts needed:

1) E282 shell DIY kit, can only be found on Taobao.

2) A pair of 16mm Sony drivers, either from the E2xx or E4xx series.

3) Old school cable with 1.5mm OD wire.

4) Super glue, the best you can get. I used Ergo by Kisling Switzerland

5) Headphone glue, i.e. G-S Hypo Cement, E7000, or anything similar

6) Soldering supply

7) Optional: UV solder mask.

The above is all the E282 kit comes with (from top left): tail caps, rubber tubes cut to pointy end, old-school cable Y-splitter, the main shells (with strain relief already inserted), rubber rings for securing the drivers., dampening foam pads, metal grill and driver mounts. Note that you don't need to use the metal grill if your driver still has its original metal grill. But if you do want to use the metal grill, you might need to find some metal mash for the front and tuning paper at the back, depending on how you like to tune the drivers. This particular kit above is copper with rose gold finish.

Here is the original E262 I got from Japan and the old-school cable I got from an old Cresyn earbud. The cable must be thin enough so it will go through the strain relief of the replacement shell.

Note that these kind of old-school cables usually has color-coded plastic insulated wires inside (red for right, green for left, and copper for ground). You will need to expose around 25~30mm of the cable as shown in the picture above.

Take the strain relief out of the metal housing and slide it onto the cable. Put the super glue on the area marked in red, then slide the strain relief up slowly till only the exposed wire is left hanging out. Take note that you will NOT be able to adjust the cable from this point forward, so you will want more than enough exposed wires than just enough as it will be much easier to cut away any excess.

Wait till the super glue is dried completely, then insert the strain relief and wires into the housing. Again, make sure enough wire is left so soldering will be easier. Now put some normal glue to the metal housing and glue the dampening foam in place, as marked by the white arrows.

Now compress the rubber pointy tube slightly and insert it into the socket / groove of the metal shell. Push it down toward the strain relief as much as you can, though it will not fit completely inside by design. The pointy end will curve up and that's normal. Just be sure that the rubber tube will still form an open vent to redirect air downward.

Now prepare the wire by burning off the plastic coating using the soldering iron, then solder the driver in as shown by the picture and arrows. This is done to minimize any of the wires shorting with the metal housing as the housing themselves are highly conductive (the original housing is plastic and doesn't have this issue). I will highly recommend you to apply some UV soldering mask to both the soldering joint as well as the wires just to add an extra layer of safety.

Adjust the driver mount (*white arrow) so it will sit tightly with the driver, then insert the driver into the metal shell while making sure the soldering joint will be parallel to the shell's socket (*red marking)

Put on the rubber ring to secure the driver and insert the tail cap to secure the strain relief. Enjoy.

------------------------------------

Below is another reshelling using MDR-A22 driver with silver metal shell with gold finish. A22 is around the same timeframe as E484 and was said to have the same driver as E484. It is also extremely rare and I got very lucky as it was included in a bundle sale with a Walkman.

Afterthought: This is overall an easy but expensive build, with a very satisfying result nonetheless. In the end, I have two really unique and great-sounding earbuds out of the built, even though it certainly took me quite some effort. Last but not least - if you are looking for great-sounding earbuds, you can probably find modern, still-in-production earbuds that are better than these reshelled Sony with equal if not better value. While I still consider what I have built to be excellent, this project also has a lot to do with nostalgic as well as preservative reasons rather than purely about SQ.

Last edited:

I have one of these available for sale if anyone would like. ClieOS Planar

Done.

Pretty amazing sounding, if I say so myself.

faichiu

500+ Head-Fier

- Joined

- Mar 10, 2007

- Posts

- 673

- Likes

- 22

Sony MDR-E282 reproduction shell Kit Build

This kit is made by the same Chinese DIYer that offers the V55 kit which I have previously built. E282 is really one of the first generations of high-end earbuds of its time, featuring 16mm drivers (*the other common size of its time is 13.5mm). Technically this is a simpler build than the V55 kit, the issue is mainly that E282 has a rather shallow magnet (which is fairly typical of its era) and thus you can't just simply use any 16mm driver as the back end will likely not fit inside the metal shell. My conclusion is that, if you want to build this kit, it is better to keep to the 16mm drivers from MDR-E2xx and MDR-4xx series. Anything newer might not fit. As part of this rebuild, I actually spent almost 2 months scouting various auction sites to hunt for suitable drivers. Besides eBay, the best place I found is the Yahoo Japan Auction site. For those living outside of Japan or can't read Japanese, you can use Buyee.jp for its betting, buying, and forwarding services. Below are some extra info regarding all major Sony earbuds generation:

MDR-E1xx series: mono earbud, pre-early 80s, mostly for portable FM radio which hadn't really offered any stereo sound yet.

MDR-E2xx series: E262, E272, and E282 as top-end models, featuring sapphire or diamond-plated diaphragm

MDR-E4xx series: E464 and E484 as the top-end models with the latter often being considered to be the best earbuds Sony ever made.

MDR-E5xx series: E565 and E575 as the top-end models

MDR-E7xx series: E737 and E747 as the top-end models

MDR-E8xx series: E868 and E888 as the top-end models

Anything beyond E8xx series is not worth bothering, including the E9xx and E0xxx series

For the most part, I won't recommend getting E282 or E484 for the DIY project unless you already have a pair at hand, as they are extremely rare and astronomically expensive. For the demonstration below, I am using a pair of E262 drivers that I got from the Japan Yahoo auction site. It was about US$130 with all the associated Buyee fees, including international shipping. A typical good condition E262 will likely cost close to, if not over US$200. I got it cheap because the pair I got is labeled as 'junk' or not working. I took a chance and it turned out to be just a cable issue (the original cable had cracked, which is common for old earbuds). Given the ideal is to reshell the earbud with new cable anyway, it would be logical to hunt for cheaper, less-than-ideal condition earbuds for the project rather than those in good condition that have a high price tag. However do note that anything labeled as 'junk' could literally just be junk and you might not get any good driver out of it, as in the nature of any auction. If you don't really want to spend more than $100 for the drivers, go and look for E472 instead. E472 is often referred to as the lesser-sounding, cheaper but still really good alternative of E484. It had been extensively used by Sony as the stock earbud for its higher-end cassette Walkman models and thus it is easier and cheaper to find (with a good working pair often just under $100). Some reports from the Chinese DIY community have even suggested that reshelled E472 can almost rival that of reshelled E484.

Last but not least, the E282 DIY kit is not cheap. It comes in two main versions: Silver alloy is around $150 and copper alloy is around $107. They also have various outer color finishes. Both versions are of great quality and it is almost impossible to tell apart.

Tools and parts needed:

1) E282 shell DIY kit, can only be found on Taobao.

2) A pair of 16mm Sony drivers, either from the E2xx or E4xx series.

3) Old school cable with 1.5mm OD wire.

4) Super glue, the best you can get. I used Ergo by Kisling Switzerland

5) Headphone glue, i.e. G-S Hypo Cement, E7000, or anything similar

6) Soldering supply

7) Optional: UV solder mask.

The above is all the E282 kit comes with (from top left): tail caps, rubber tubes cut to pointy end, old-school cable Y-splitter, the main shells (with strain relief already inserted), rubber rings for securing the drivers., dampening foam pads, metal grill and driver mounts. Note that you don't need to use the metal grill if your driver still has its original metal grill. But if you do want to use the metal grill, you might need to find some metal mash for the front and tuning paper at the back, depending on how you like to tune the drivers. This particular kit above is copper with rose gold finish.

Here is the original E262 I got from Japan and the old-school cable I got from an old Cresyn earbud. The cable must be thin enough so it will go through the strain relief of the replacement shell.

Note that these kind of old-school cables usually has color-coded plastic insulated wires inside (red for right, green for left, and copper for ground). You will need to expose around 25~30mm of the cable as shown in the picture above.

Take the strain relief out of the metal housing and slide it onto the cable. Put the super glue on the area marked in red, then slide the strain relief up slowly till only the exposed wire is left hanging out. Take note that you will NOT be able to adjust the cable from this point forward, so you will want more than enough exposed wires than just enough as it will be much easier to cut away any excess.

Wait till the super glue is dried completely, then insert the strain relief and wires into the housing. Again, make sure enough wire is left so soldering will be easier. Now put some normal glue to the metal housing and glue the dampening foam in place, as marked by the white arrows.

Now compress the rubber pointy tube slightly and insert it into the socket / groove of the metal shell. Push it down toward the strain relief as much as you can, though it will not fit completely inside by design. The pointy end will curve up and that's normal. Just be sure that the rubber tube will still form an open vent to redirect air downward.

Now prepare the wire by burning off the plastic coating using the soldering iron, then solder the driver in as shown by the picture and arrows. This is done to minimize any of the wires shorting with the metal housing as the housing themselves are highly conductive (the original housing is plastic and doesn't have this issue). I will highly recommend you to apply some UV soldering mask to both the soldering joint as well as the wires just to add an extra layer of safety.

Adjust the driver mount (*white arrow) so it will sit tightly with the driver, then insert the driver into the metal shell while making sure the soldering joint will be parallel to the shell's socket (*red marking)

Put on the rubber ring to secure the driver and insert the tail cap to secure the strain relief. Enjoy.

------------------------------------

Below is another reshelling using MDR-A22 driver with silver metal shell with gold finish. A22 is around the same timeframe as E484 and was said to have the same driver as E484. It is also extremely rare and I got very lucky as it was included in a bundle sale with a Walkman.

Afterthought: This is overall an easy but expensive build, with a very satisfying result nonetheless. In the end, I have two really unique and great-sounding earbuds out of the built, even though it certainly took me quite some effort. Last but not least - if you are looking for great-sounding earbuds, you can probably find modern, still-in-production earbuds that are better than these reshelled Sony with equal if not better value. While I still consider what I have built to be excellent, this project also has a lot to do with nostalgic as well as preservative reasons rather than purely about SQ.

Hi, when I click on the taobao link, the diy shell has no Sony logo and model? But your picture has it?

The seller is trying to avoid showing any marking that could anger the Sony legal department.Hi, when I click on the taobao link, the diy shell has no Sony logo and model? But your picture has it?

sofastreamer

Headphoneus Supremus

- Joined

- Dec 14, 2007

- Posts

- 2,524

- Likes

- 1,694

any news from the planar earbud endeavors?

There isn't any further plan for planar earbuds atm.any news from the planar earbud endeavors?

faichiu

500+ Head-Fier

- Joined

- Mar 10, 2007

- Posts

- 673

- Likes

- 22

do you know the seller in person? If I make a purchase does it comes with sony logo?The seller is trying to avoid showing any marking that could anger the Sony legal department.

You can use the Taobao app to contact the seller directly before any purchase.do you know the seller in person? If I make a purchase does it comes with sony logo?

iBasso CB19 C-to-C cable mod for Type-C PD power source

One of the problems of any better-than-decent USB dongle is that they tend to draw a lot of power from the smartphone. So dongle makers began to release cables like iBasso CB19 to address the issue - By using an external power source, likely a power bank, to stop the USB dongle from draining the smartphone. However, most of these type of cable use USB-A for connecting the power source, likely a safety and convenient feature because USB-A is inherently 'dumb' and limits itself to a safe 5V, where the newer Typc-C connection introduces Power Delivery (PD) feature that can scale up to 20V and potentially poses an risk to USB dongle which only required 5V. Of course, this really doesn't help when USB-A is getting phased out by more and more power bank makers where only Type-C is used to both charge and discharge the power bank. On one occasion, I actually tried to 'trick' my Type-C power bank to power my iBasso DC-Elite via CB19 using a simple USB-A-toType-C convertor, which ended up completely destroying my DC-Elite (* I assumed somehow higher voltage was trigger in the process) - this is a super expensive lesson to learn on why USB-A is chosen in the first place. Anyway, fast forward a few weeks later, I came across another item I already owned - a Type-C PD triggering device that allows the user to trick any PD wall adapter to output any selected voltage. Basically, this allows the user to use a regular PD wall adapter to supply voltage to a device that is not meant to use a Type-C connection. For example, you can use these triggers (*usually in the form of a Type-C cable with a barrel / DC connector at the other end) to supply 12V from the Type-C PD wall adapter to an internet router. So putting two together, I realize I could integrate the trigger into the CB19 and force any Type-C PD power source to limit its output to a fixed 5V, thus avoiding any of the risk coming from the PD smart feature.

Tools and parts needed:

1) iBasso CB19 - technically any similar external powering Type-C to C cable will work, but I like CB19 for overall quality and I got one for cheap.

2) A Type-C 5V triggering connector (this is the one I got)

3) USB breakout tester board

4) Multimeter + Type-C voltage tester

5) Soldering supply + heat gun

6) Glue gun + heatshrink

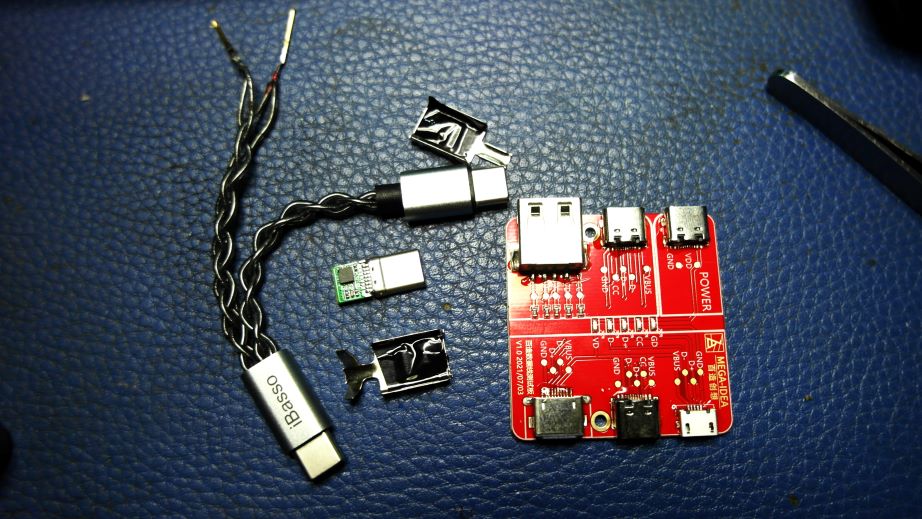

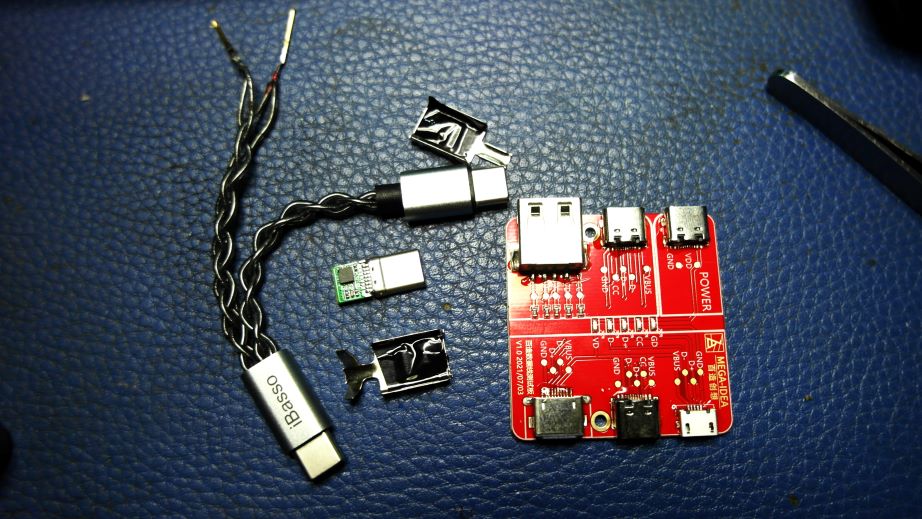

CB19 on the right and Type-C 5V trigger connector on the left. You can see there is an eMarker chip on the Type-C connector that is used to control what voltage you will get. There are two solder pads on the back - one for V (for +5V) and one for G (ground).

The first thing to do is to remove the USB-A connector from CB19 - you can just cut it off, but I prefer to heat the USB-A metal housing until I can pull the cable out, thus making sure I can preserve the overall length of an already pretty short cable. You can see the two USB-A pins will come out with the cable. Now you need to connect the other side of the CB19 (*the Type-C end with the 'iBasso' logo) to the USB breakout board and use a multimeter to figure out which of the USB-A pins are VCC (+5V) and GND (ground). Once you figure out which is which, desolder the USB-A pins and solder the cable to the Type-C triggering connector. I picked a metal shell for my Type-C trigger board, so I put some insulating tape on the inside of the metal shell. It will be further filled with hot glue, so it kinda works as double insulation. You can use a plastic shell if you want to keep it simple.

This is just a simple test using a Type-C voltage tester and FiiO Retro Nano (*no particular reason to use this except it was the closest thing on the table for me to grab at the time, plus it isn't that expensive even if I broke it). The power bank below has only one Type-C port and is notorious for not wanting to charge anything that is not 'smart' / PD compatible. So this is a good way to show that the trigger connector does work as intended, supplying 5V without any issue.

Here is the last bit - testing with FiiO KA17. You can see the smartphone isn't supplying much power while the main power is coming from the power bank, roughly 1.2W as KA17 is on desktop mode, while still stable at around 5.2V as intended.

Afterthought: The mod is a complete success. I also tested the same setup with a different power bank's Type-C port without any problem. The voltage might be a bit higher or lower (it can go +/-0.25V from 5V) depending mainly on the design of the power bank circuit, but that is normal and within expected USB tolerance (again, +/-0.25 from 5V). The Type-C trigger board doesn't in itself does any voltage conversion. It only tells what kind of voltage for the power bank to output instead of letting the power bank to find out for itself (which could either go wrong or simply refuse to output any voltage when the other side of the connection doesn't respond or respond wrongly). In any case, I hope this mod will find itself into actual commercial product in near future as more and more power bank only come with Type-C port.

One of the problems of any better-than-decent USB dongle is that they tend to draw a lot of power from the smartphone. So dongle makers began to release cables like iBasso CB19 to address the issue - By using an external power source, likely a power bank, to stop the USB dongle from draining the smartphone. However, most of these type of cable use USB-A for connecting the power source, likely a safety and convenient feature because USB-A is inherently 'dumb' and limits itself to a safe 5V, where the newer Typc-C connection introduces Power Delivery (PD) feature that can scale up to 20V and potentially poses an risk to USB dongle which only required 5V. Of course, this really doesn't help when USB-A is getting phased out by more and more power bank makers where only Type-C is used to both charge and discharge the power bank. On one occasion, I actually tried to 'trick' my Type-C power bank to power my iBasso DC-Elite via CB19 using a simple USB-A-toType-C convertor, which ended up completely destroying my DC-Elite (* I assumed somehow higher voltage was trigger in the process) - this is a super expensive lesson to learn on why USB-A is chosen in the first place. Anyway, fast forward a few weeks later, I came across another item I already owned - a Type-C PD triggering device that allows the user to trick any PD wall adapter to output any selected voltage. Basically, this allows the user to use a regular PD wall adapter to supply voltage to a device that is not meant to use a Type-C connection. For example, you can use these triggers (*usually in the form of a Type-C cable with a barrel / DC connector at the other end) to supply 12V from the Type-C PD wall adapter to an internet router. So putting two together, I realize I could integrate the trigger into the CB19 and force any Type-C PD power source to limit its output to a fixed 5V, thus avoiding any of the risk coming from the PD smart feature.

Tools and parts needed:

1) iBasso CB19 - technically any similar external powering Type-C to C cable will work, but I like CB19 for overall quality and I got one for cheap.

2) A Type-C 5V triggering connector (this is the one I got)

3) USB breakout tester board

4) Multimeter + Type-C voltage tester

5) Soldering supply + heat gun

6) Glue gun + heatshrink

CB19 on the right and Type-C 5V trigger connector on the left. You can see there is an eMarker chip on the Type-C connector that is used to control what voltage you will get. There are two solder pads on the back - one for V (for +5V) and one for G (ground).

The first thing to do is to remove the USB-A connector from CB19 - you can just cut it off, but I prefer to heat the USB-A metal housing until I can pull the cable out, thus making sure I can preserve the overall length of an already pretty short cable. You can see the two USB-A pins will come out with the cable. Now you need to connect the other side of the CB19 (*the Type-C end with the 'iBasso' logo) to the USB breakout board and use a multimeter to figure out which of the USB-A pins are VCC (+5V) and GND (ground). Once you figure out which is which, desolder the USB-A pins and solder the cable to the Type-C triggering connector. I picked a metal shell for my Type-C trigger board, so I put some insulating tape on the inside of the metal shell. It will be further filled with hot glue, so it kinda works as double insulation. You can use a plastic shell if you want to keep it simple.

This is just a simple test using a Type-C voltage tester and FiiO Retro Nano (*no particular reason to use this except it was the closest thing on the table for me to grab at the time, plus it isn't that expensive even if I broke it). The power bank below has only one Type-C port and is notorious for not wanting to charge anything that is not 'smart' / PD compatible. So this is a good way to show that the trigger connector does work as intended, supplying 5V without any issue.

Here is the last bit - testing with FiiO KA17. You can see the smartphone isn't supplying much power while the main power is coming from the power bank, roughly 1.2W as KA17 is on desktop mode, while still stable at around 5.2V as intended.

Afterthought: The mod is a complete success. I also tested the same setup with a different power bank's Type-C port without any problem. The voltage might be a bit higher or lower (it can go +/-0.25V from 5V) depending mainly on the design of the power bank circuit, but that is normal and within expected USB tolerance (again, +/-0.25 from 5V). The Type-C trigger board doesn't in itself does any voltage conversion. It only tells what kind of voltage for the power bank to output instead of letting the power bank to find out for itself (which could either go wrong or simply refuse to output any voltage when the other side of the connection doesn't respond or respond wrongly). In any case, I hope this mod will find itself into actual commercial product in near future as more and more power bank only come with Type-C port.

Last edited:

sofastreamer

Headphoneus Supremus

- Joined

- Dec 14, 2007

- Posts

- 2,524

- Likes

- 1,694

awesome! thank you for sharing! powerbank looks nice, is its battery swapable?

Last edited:

Yep, it takes 21700 battery or 18650 with adapter.awesome! thank you for sharing! powerbank looks nice, is its battery swapable?

sofastreamer

Headphoneus Supremus

- Joined

- Dec 14, 2007

- Posts

- 2,524

- Likes

- 1,694

would you mind posting a link?Yep, it takes 21700 battery or 18650 with adapter.

You can find it on AE, search for BT20 MK2 or BT20 Wingmanwould you mind posting a link?

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)