khbaur330162

Vintage Ortho Ninja 🥷

- Joined

- Aug 5, 2006

- Posts

- 2,010

- Likes

- 1,825

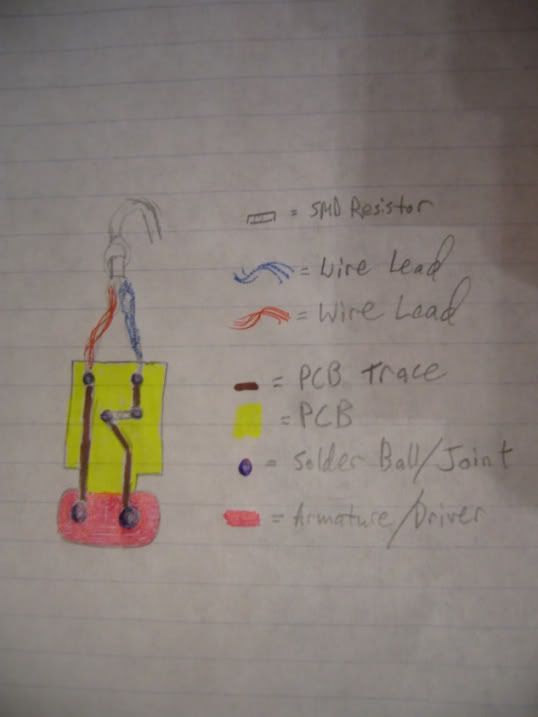

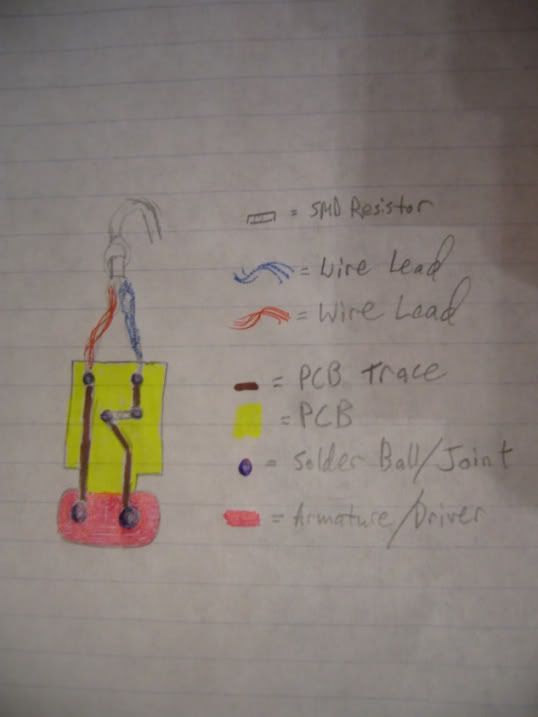

Has anyone actually opened the driver housing on their iM716's? I did for both my iM716 and iM616 and they have a single tiny surface mount resistor for each channel. I'm not really sure what they are even for.

I bought some 75 ohm resistors for the podectomy, going a little high in value due to my plan of simply removing the entire mini PCB for the sake of a recable, however, I'm now having second thoughts. Does anyone think removing these resistors could have a negative effect on sound quality?

Here's a few pictures of the internals, along with a quick diagram I drew because it's a little hard to see what's going on with everything being so tiny.

On the resistor itself is the number "0" printed in white lettering for the iM716's left channel, and "000" for the right. For the iM616 it's "180" for both.

I bought some 75 ohm resistors for the podectomy, going a little high in value due to my plan of simply removing the entire mini PCB for the sake of a recable, however, I'm now having second thoughts. Does anyone think removing these resistors could have a negative effect on sound quality?

Here's a few pictures of the internals, along with a quick diagram I drew because it's a little hard to see what's going on with everything being so tiny.

On the resistor itself is the number "0" printed in white lettering for the iM716's left channel, and "000" for the right. For the iM616 it's "180" for both.