HiGHFLYiN9

Member of the Trade: Zynsonix

Looks great!! Good 'ol Neutrik locking TRS and Alps Blue, can't go wrong with either. Do you have a Greenlee punch for the DIN size stuff?

Do you have a Greenlee punch for the DIN size stuff?

I have four of them, one for DIN connectors and the rest for tube sockets. They're exquisitely expensive but worth it if you build a lot. Great for aluminum, steel and copper as long as it's not super thick. It won't bend it. I've heard of people running into problems with diecast metal, but I've personally had no issues. Gives a super clean cut... no need for deburring, etc.

Looking forward to see that 3D printed panel when you're back up and running

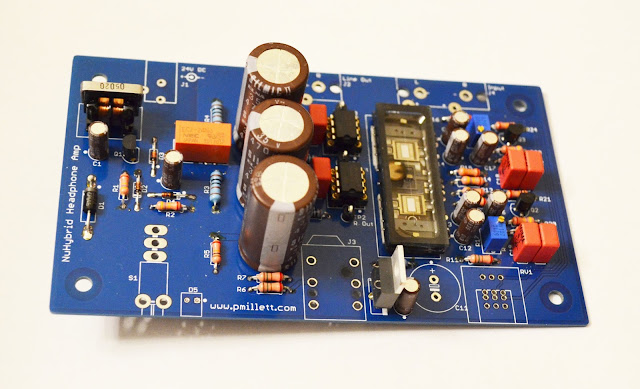

As far as my NuHybrid, the parts are coming... I just have to be patient.Trying to decide between a Hammond case and a cigar box for enclosure.

I just cut my panels with an abrasive waterjet system.