cgrums

100+ Head-Fier

- Joined

- Oct 27, 2006

- Posts

- 246

- Likes

- 10

Having just finished a

CMOY

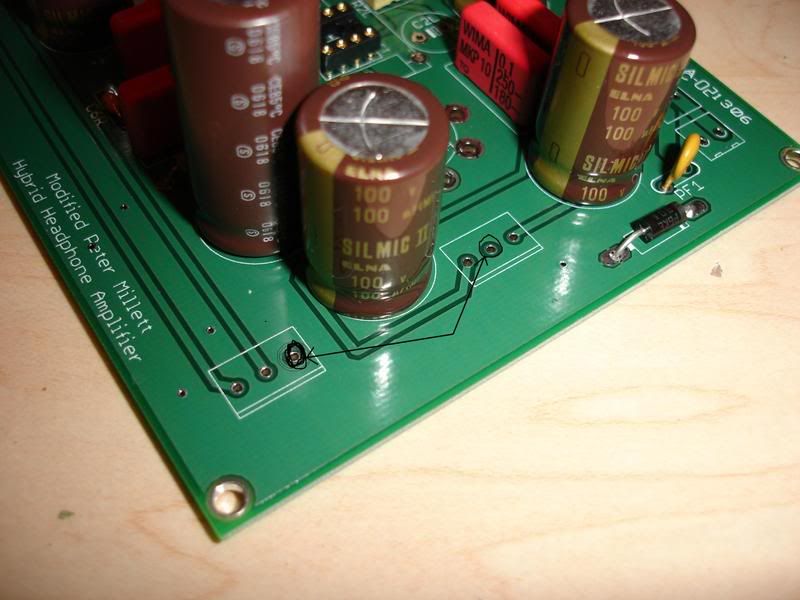

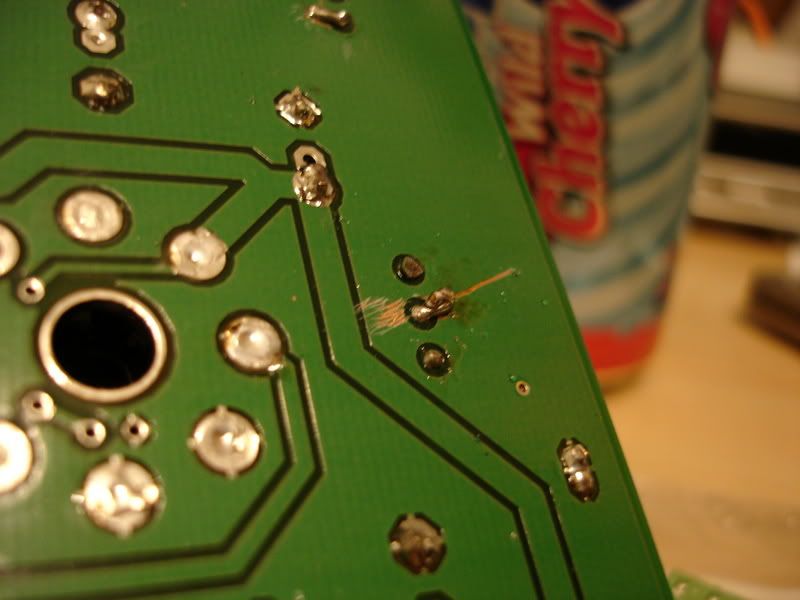

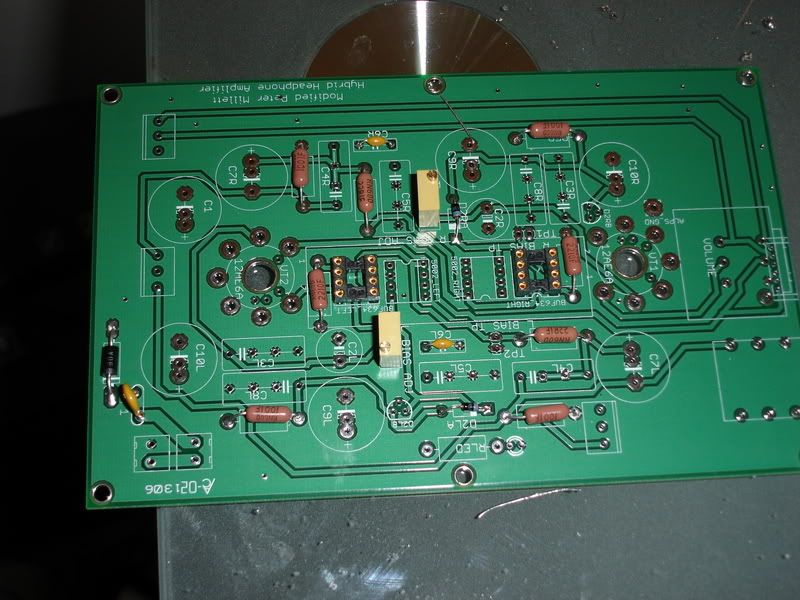

And a Pimeta with Panasonic FM caps, class A biasing, stacked buf634s and AD8620/8610 opamps. Thanks again to Tomb, Tangent and everyone else for answering all of my amateur questions

(The current panel components are temporary hence the less-than perfect finishing):

(The current panel components are temporary hence the less-than perfect finishing):

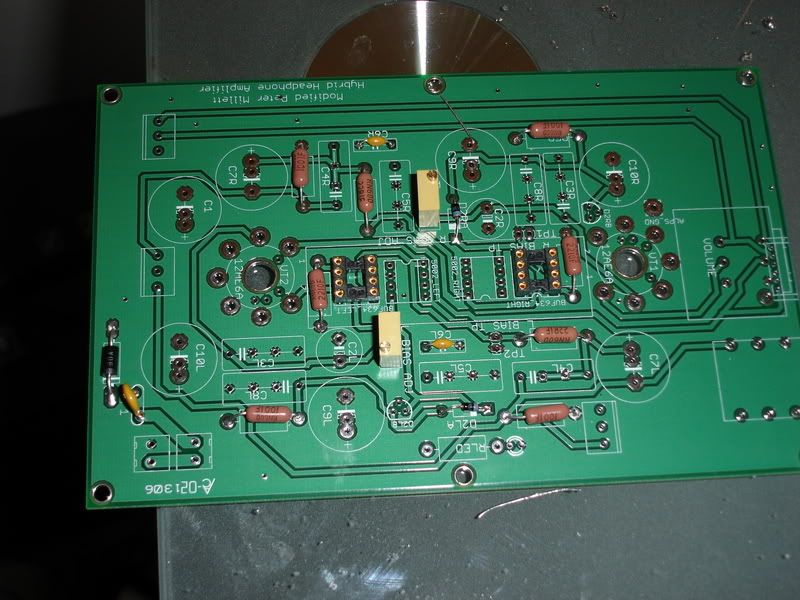

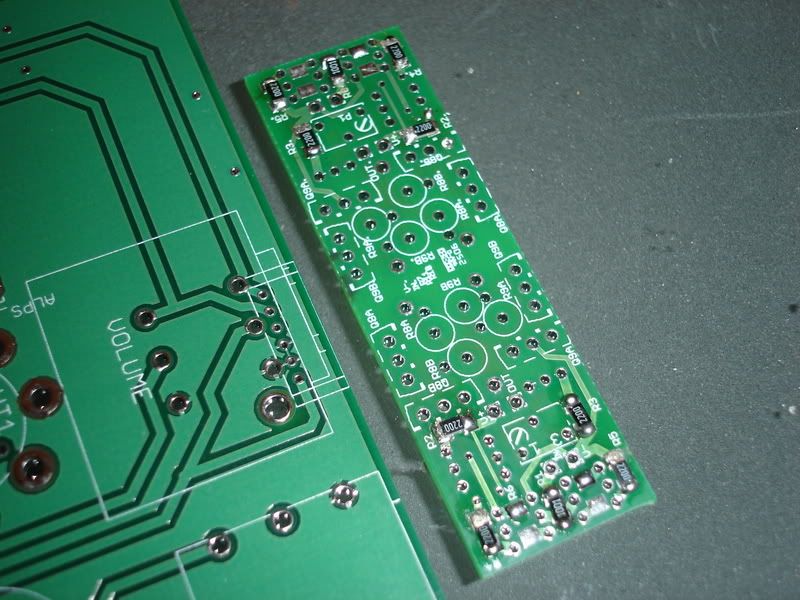

I have now started a new project:

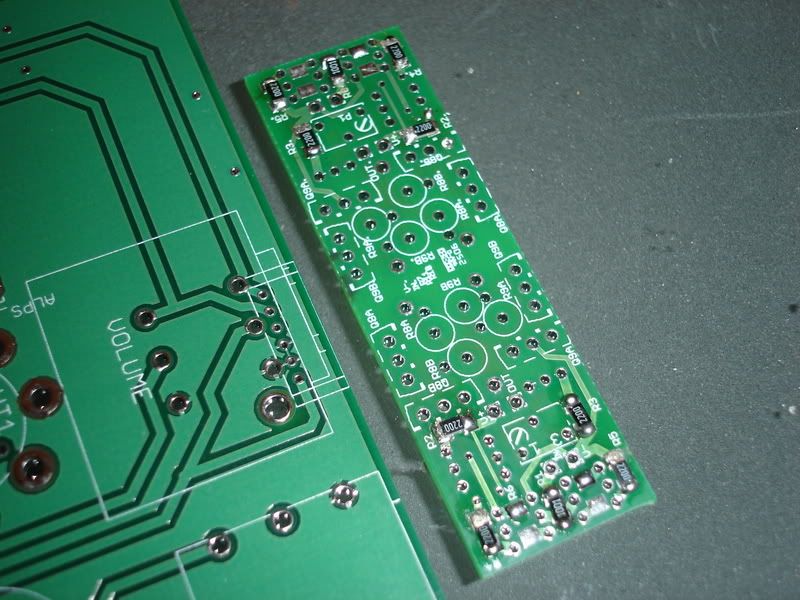

This is definitely my first foray into the world of smd (excluding the AD8620/10 onto browndog adaptors) and I think I'm getting the hang of it.

I have all the parts either here or enroute and am curious about capacitors. I'm planning to use BG standard on both C7 and C2 and Elna Silmic IIs on everything else. I've been reading a fair amount on not bypassing C7/C2 if using high enough quality caps and am fairly certain I want to leave the film caps unpopulated. It's clear to me from looking at the board that C4 is bypassing C7, is it C3 that bypasses C2? If it is then that should be unpopulated as well. Should I leave the rest of the box caps in?

Another question: how important is transistor matching in the buffer? I'm reading different opinions and am kind of confused here. (I know I've seen a schematic for a simple circuit that is used to match the transistors so it shouldn't be that bad...right?)

I'm hoping to document my Millett build better than my previous two to share my experience and hopefully get feedback before I screw anything up permanently.

Cheers

Cgrums

CMOY

And a Pimeta with Panasonic FM caps, class A biasing, stacked buf634s and AD8620/8610 opamps. Thanks again to Tomb, Tangent and everyone else for answering all of my amateur questions

I have now started a new project:

This is definitely my first foray into the world of smd (excluding the AD8620/10 onto browndog adaptors) and I think I'm getting the hang of it.

I have all the parts either here or enroute and am curious about capacitors. I'm planning to use BG standard on both C7 and C2 and Elna Silmic IIs on everything else. I've been reading a fair amount on not bypassing C7/C2 if using high enough quality caps and am fairly certain I want to leave the film caps unpopulated. It's clear to me from looking at the board that C4 is bypassing C7, is it C3 that bypasses C2? If it is then that should be unpopulated as well. Should I leave the rest of the box caps in?

Another question: how important is transistor matching in the buffer? I'm reading different opinions and am kind of confused here. (I know I've seen a schematic for a simple circuit that is used to match the transistors so it shouldn't be that bad...right?)

I'm hoping to document my Millett build better than my previous two to share my experience and hopefully get feedback before I screw anything up permanently.

Cheers

Cgrums