The way I do it (don't have a pic yet but i'll post on the next one I build) but for pins 2 and 3 before I put on the wires, I put a blob of glue where they go into the connector and only leave about 1mm of pin bare, and bend them about 20 degrees apart. This way no solder can get in between them. Once they're soldered on, I glue them up, then when it dries I use end-cutters to remove any glue that's above/below the profile of the connector so she still fits into the plug body. If you pre-glue like this there's no way you can solder bridge pin 2 and 3 nor can you snap them off, I guarantee it (/George Zimmer).

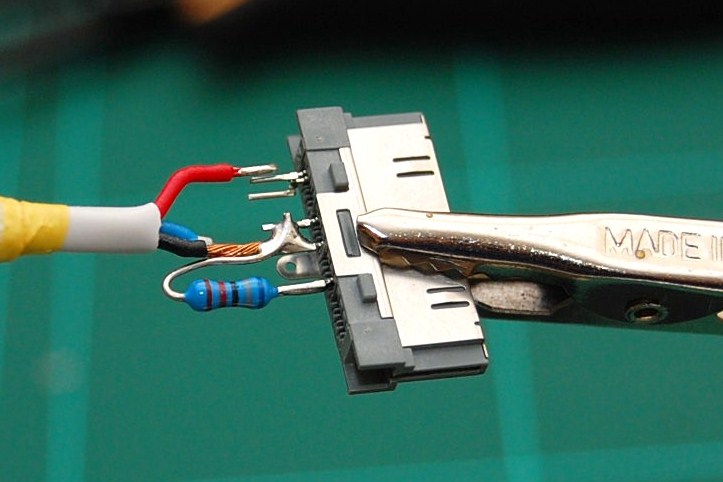

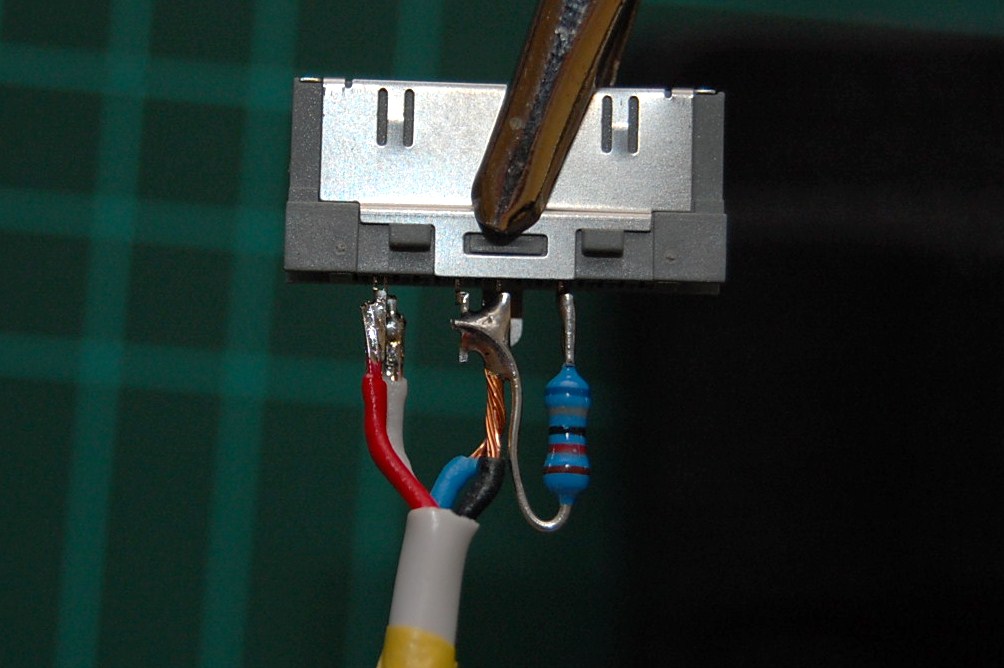

I bend pins 11 and 15 towards each other until they nearly touch, and bridge them with solder then put the ground wire right on top of that.

Although people tell me otherwise, I still find it easy to start with 3 unbraided wires, and once they're securely glued, braid them and slide the sleeving and heatshrink into the connector, secure with glue, and then snap the top onto the connector.

I think the glue-free LOD is very clever although it does make me nervous, me with my butterfingers I'd have broken it before getting that far.

I guess I could do the resistor thing next time.but it doesn't bother me much to press the button once whenever I plug the LOD in.

I think with the Jena, and the pre-gluing the space between the pins, you can just stick the jena straight on top of the pin and glue the hell out of it. For pin 2 it'd go atop the pin, and pin 1 it'd go below. That is a great idea to heat the wire to bend it into a more appropriate shape before you solder it though. I don't know why anyone would punish themselves with jena18g though, I know it has its fans but I recall Lawton Audio's website saying that 18g is not as appropriate as 22g for interconnects, that it sounds woolier and boomier (unless that's what you're after).