Not long ago I put some DIY parts in cart by the way when I was buying ChiFi earphones, including a pair of 50mm beryllium coated drivers.

Since I've built a 3d printed headphone conversion for KSC75 before---although it was a failure.

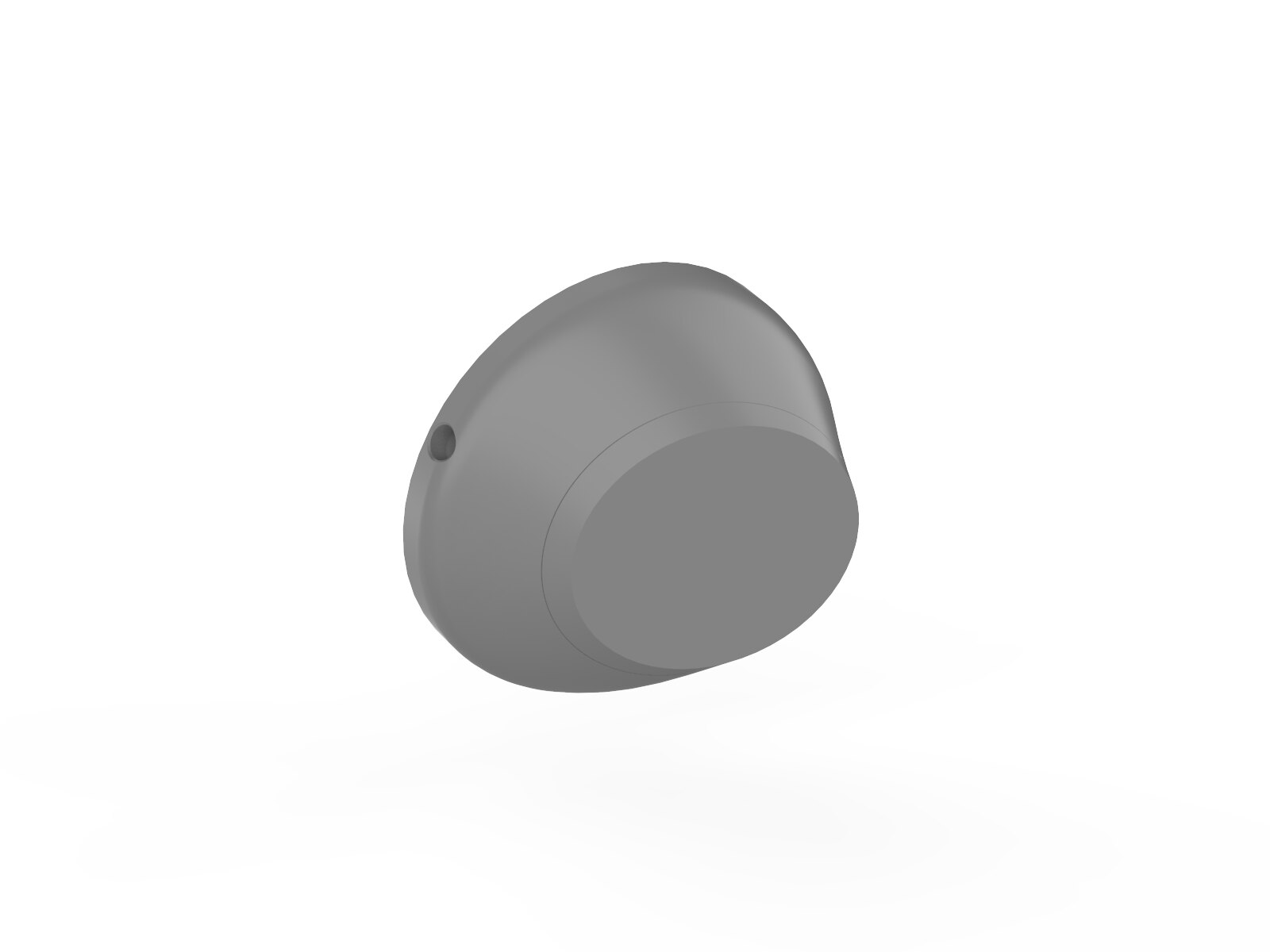

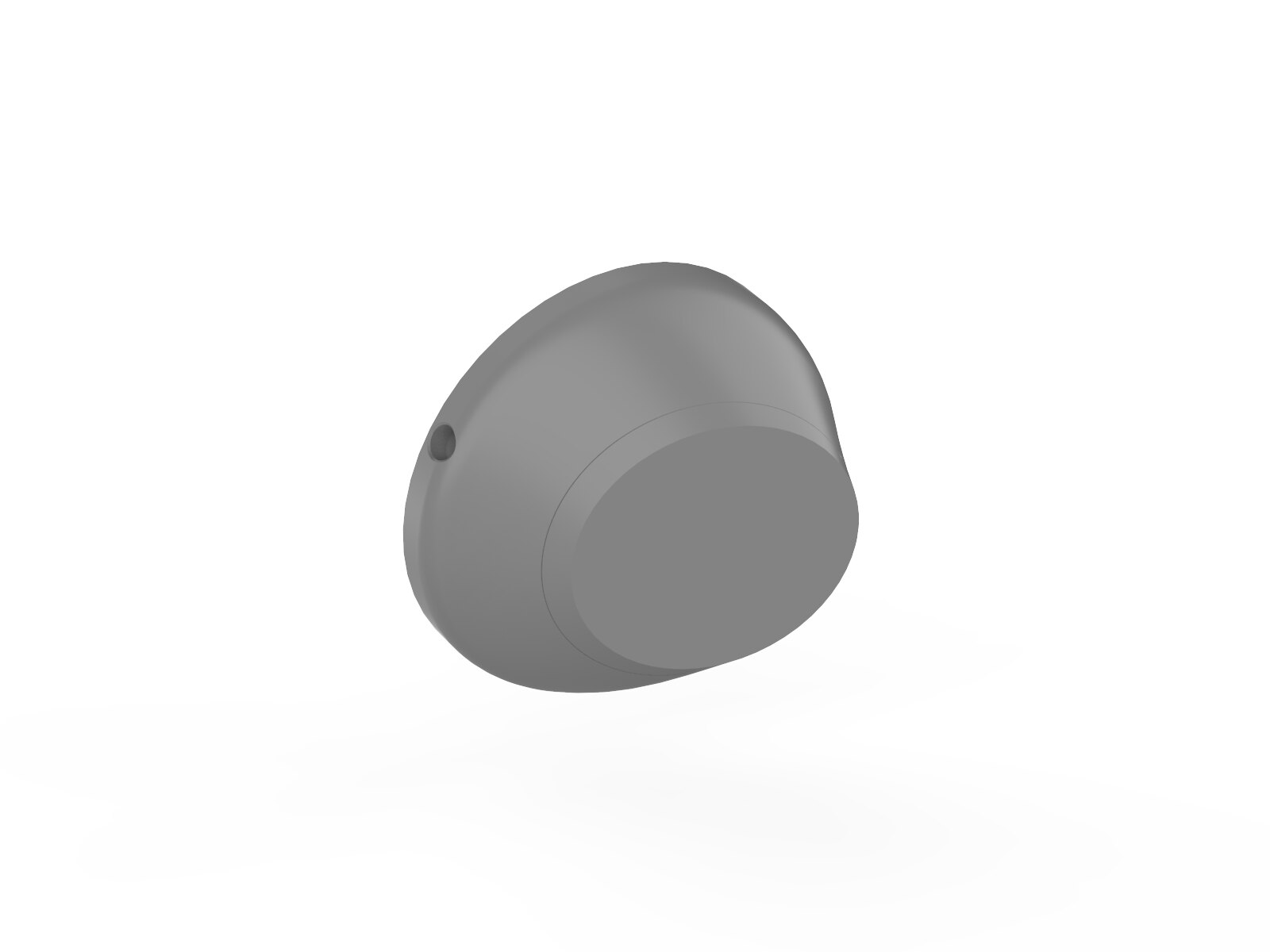

I want to do it again to see if the 3D printing headphone works. I've referenced many pictures of MDR-R10 on the Internet and made a tribute to it.

I tried my best to replicate the cup shape of R10. it is only designed with reference to the picture. Of course the measurement is impossible to be accurate.

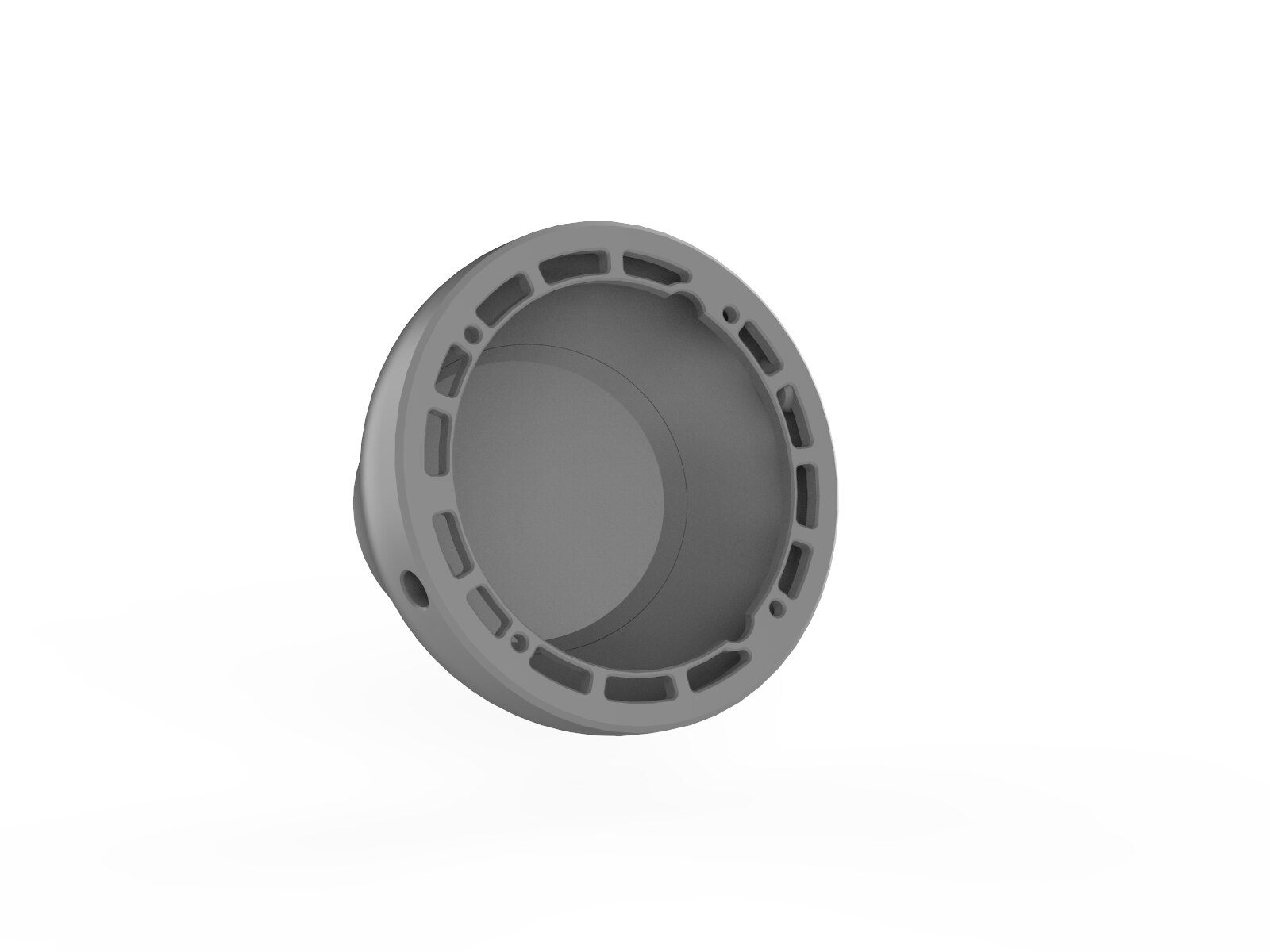

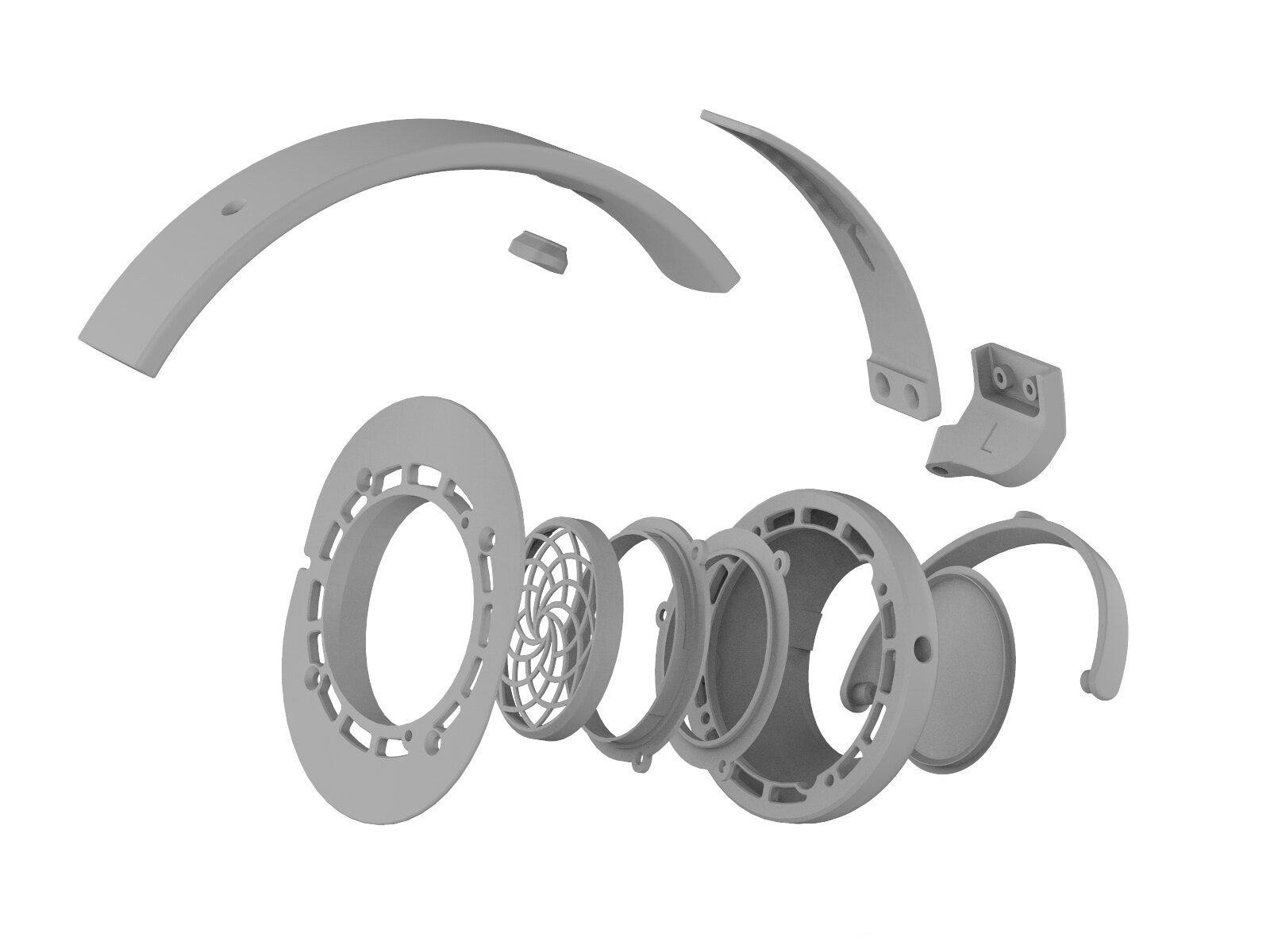

The baffle was oval because I happen to have some pads for MSR7.

I don’t have any experience in acoustic design. So I can only design with reference to my own headphones and some headphone photos.

----Too bad I have not read Frank2908's article before i did this.

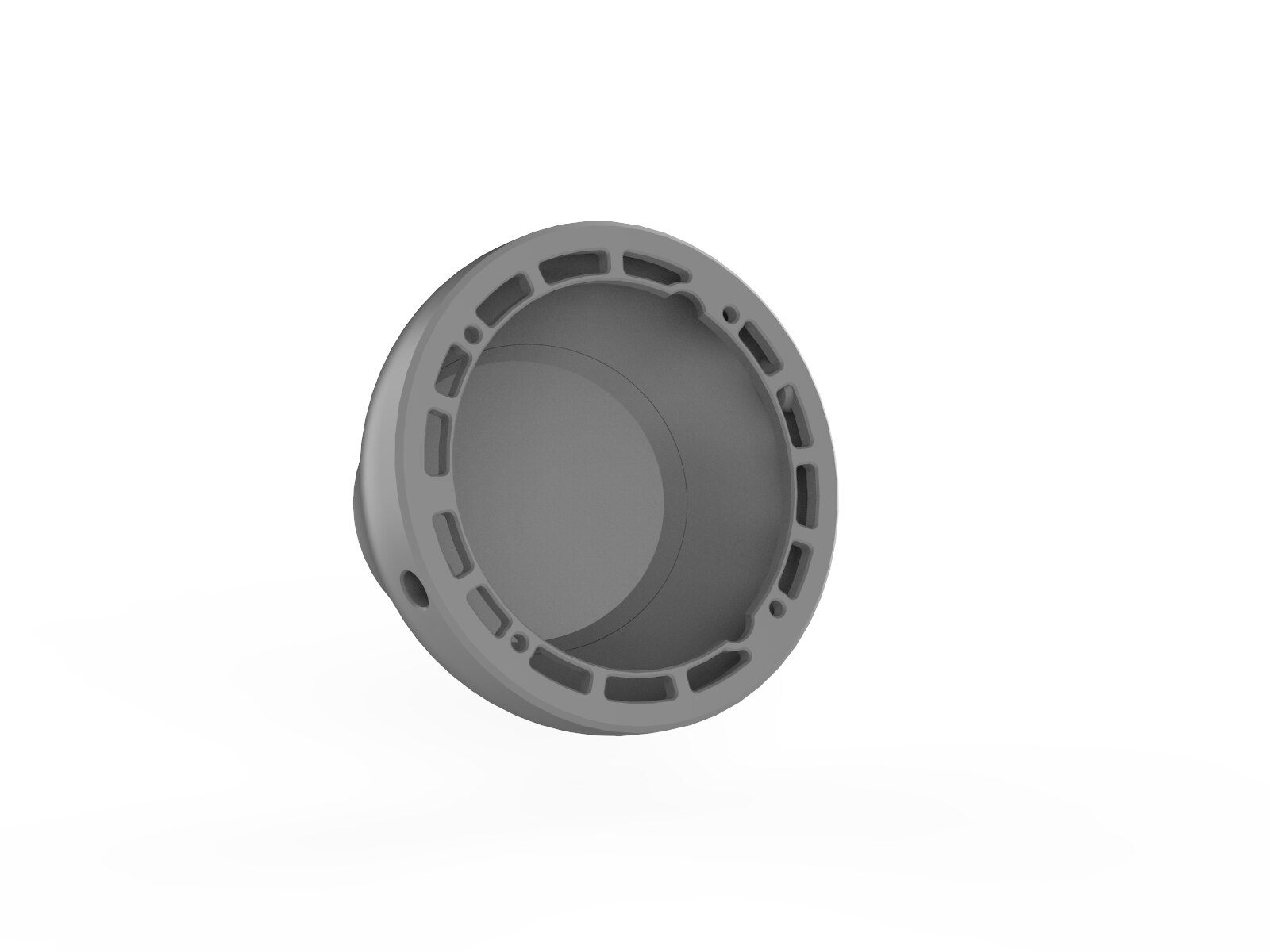

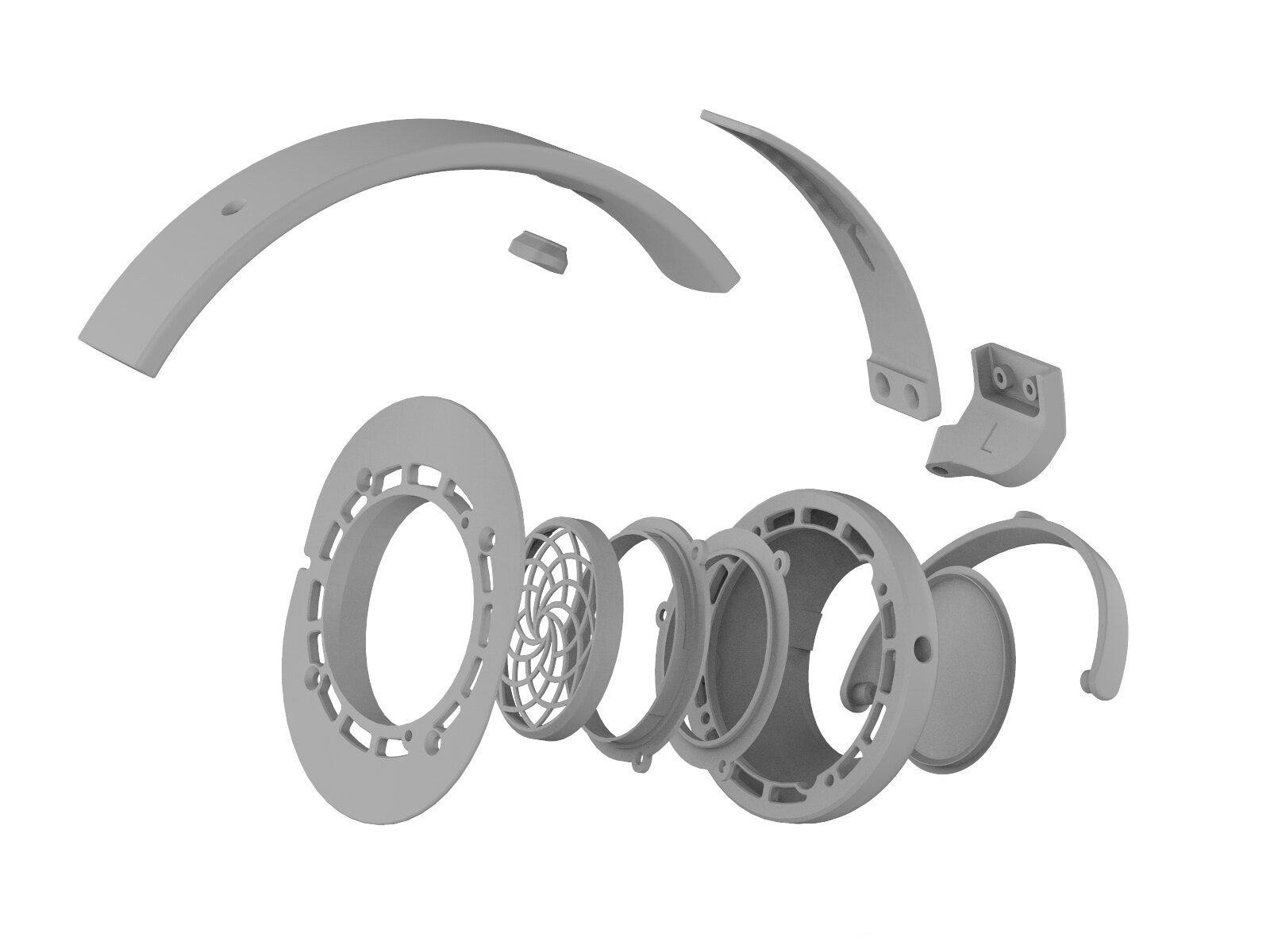

The cup is closed-back design though it has two parts I glue them together to prevent any air leakage.

The vents are all on the front side, around the drivers.

The driver compartment is tilted by 10 degrees covered with fibonacci grill.

I did not use blu-tack or dynamat in the cup. I stuffed urethane foam in it instead. And I filtered the vent with micropore tape.

By the way, the connector is MMCX since I only have MMCX for now.

It weights 203g without cable and pads. 280g with these sheepskin pads.

These beryllium coated drivers are very similar to those on the HamonicDyne headphones.

These were cheap so i guess they might be the same ones on the Helios(?

Sound-wise. With my design and damping methods. It sound V shaped quite obviously. Bass is better than i imagined.

Mids not bad. Treble is a bit hot. Lots of detail but sometimes too harsh in higher volume. Less harshness after i squeeze more foam in the cups but still there.

Soundstage is not good.

I'm thinking about how to reduce harshness farther. And I am wondering if i can improve the soundstage by drilling a few small holes in the cups.

But i'm afraid that doing so will increase the harshness.

Or maybe the driver just doesn't fit a closed-back design. I don't know.

Guess there are so much tweaks i can experiment to reach the sweet spot.

Hope I can make this a platform for me to try those mysterious Chifi driver units.

Any ideas or suggestions are much welcome.

Since I've built a 3d printed headphone conversion for KSC75 before---although it was a failure.

I want to do it again to see if the 3D printing headphone works. I've referenced many pictures of MDR-R10 on the Internet and made a tribute to it.

I tried my best to replicate the cup shape of R10. it is only designed with reference to the picture. Of course the measurement is impossible to be accurate.

The baffle was oval because I happen to have some pads for MSR7.

I don’t have any experience in acoustic design. So I can only design with reference to my own headphones and some headphone photos.

----Too bad I have not read Frank2908's article before i did this.

The cup is closed-back design though it has two parts I glue them together to prevent any air leakage.

The vents are all on the front side, around the drivers.

The driver compartment is tilted by 10 degrees covered with fibonacci grill.

I did not use blu-tack or dynamat in the cup. I stuffed urethane foam in it instead. And I filtered the vent with micropore tape.

By the way, the connector is MMCX since I only have MMCX for now.

It weights 203g without cable and pads. 280g with these sheepskin pads.

These beryllium coated drivers are very similar to those on the HamonicDyne headphones.

These were cheap so i guess they might be the same ones on the Helios(?

Sound-wise. With my design and damping methods. It sound V shaped quite obviously. Bass is better than i imagined.

Mids not bad. Treble is a bit hot. Lots of detail but sometimes too harsh in higher volume. Less harshness after i squeeze more foam in the cups but still there.

Soundstage is not good.

I'm thinking about how to reduce harshness farther. And I am wondering if i can improve the soundstage by drilling a few small holes in the cups.

But i'm afraid that doing so will increase the harshness.

Or maybe the driver just doesn't fit a closed-back design. I don't know.

Guess there are so much tweaks i can experiment to reach the sweet spot.

Hope I can make this a platform for me to try those mysterious Chifi driver units.

Any ideas or suggestions are much welcome.

Last edited: