ChaosClouds

New Head-Fier

- Joined

- May 9, 2011

- Posts

- 28

- Likes

- 11

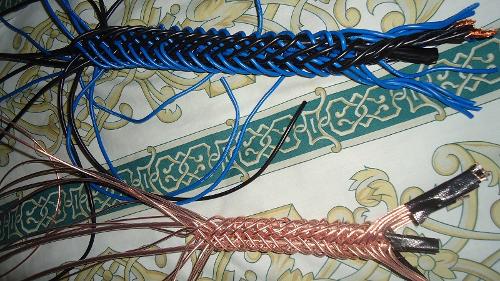

Power Cable

Sleeve: Nylon Multiflament

Conductor: 16x 1,5 mm² OCC stranded copper (8 wire for +, 8 wire for -) and 2x6 mm² OCC stranded copper

Geometry: Interlaced, Counter-Rotating,Multiple-Helix cable (Used by previous Shunyata power cable)

It's quite hard to braid this cable.

Since I had only clear color insulation, it's pretty confusing

Using different color insulation will help a lot checking some braiding mistake (after i done braiding it, I got some errors in the middle and i have to re-do it)

Put the cable into the 1" Hose

sealed one side hose with hot glue gun, filled it with steel shot, then sealed the another end using same method.(recommended by Virtual Dynamics)

Nylon Multifilament sleeving does look good indeed .

.

It's quite hard finding the way to fit the conductors to the plug (6 awg for each channel)

Done!

After 10-15 hours burn-in, compared to previous power cord I built (7 awg 1x solid core conductor each channel, using the same steel shot method), I found noticeable difference, It gives more transparency, detail, soundstage, and blacker background. However, I found some lower frequency have slightly more power on my solid core power cord.

If you want to learn to braid the cable geometry just click the link above, it will direct you to the patent website.

Sleeve: Nylon Multiflament

Conductor: 16x 1,5 mm² OCC stranded copper (8 wire for +, 8 wire for -) and 2x6 mm² OCC stranded copper

Geometry: Interlaced, Counter-Rotating,Multiple-Helix cable (Used by previous Shunyata power cable)

It's quite hard to braid this cable.

Since I had only clear color insulation, it's pretty confusing

Using different color insulation will help a lot checking some braiding mistake (after i done braiding it, I got some errors in the middle and i have to re-do it)

Put the cable into the 1" Hose

sealed one side hose with hot glue gun, filled it with steel shot, then sealed the another end using same method.(recommended by Virtual Dynamics)

Nylon Multifilament sleeving does look good indeed

.

.It's quite hard finding the way to fit the conductors to the plug (6 awg for each channel)

Done!

After 10-15 hours burn-in, compared to previous power cord I built (7 awg 1x solid core conductor each channel, using the same steel shot method), I found noticeable difference, It gives more transparency, detail, soundstage, and blacker background. However, I found some lower frequency have slightly more power on my solid core power cord.