JWFokker

500+ Head-Fier

- Joined

- Mar 8, 2005

- Posts

- 508

- Likes

- 10

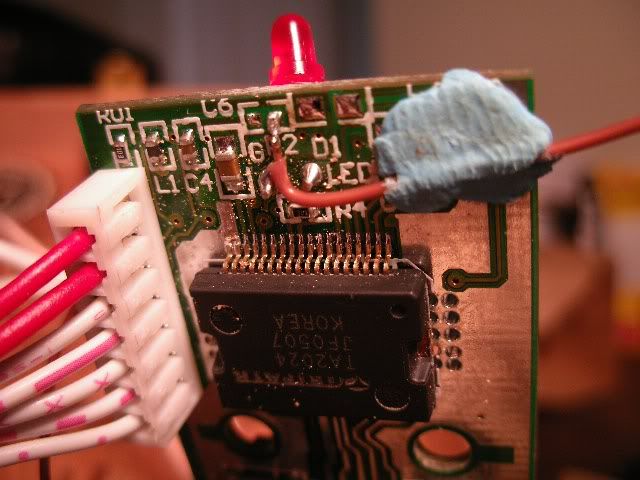

If you do choose to replace the stock input caps and resistors, use fine gauge wire, like 30awg or so, otherwise you'll have a hell of a time getting it to stick to the pad on the board.

The best thing to do, is to get your film cap (2.2-3.3uf), solder the 22k resistor and cap together. They both have long leads on them, so just wrap the resistor lead around the cap lead and solder 'em together. Place the cap/res where you want it in the amp case. The closer to the amp itself, the better. Secure it with tape or glue so it doesn't move around and pull on the thin wire. At this point, you should solder the thin wire to your film cap and then solder the other end to the pad on the board. Do the same for the resistor end and run that to your input connector or appropriate potentiometer tab. Repeat the process for the other channel.

This guy uses Black Gate capacitors in his diagram, but really, film caps are much better than even Black Gates. Even cheap Solen caps from Parts Express are as good or better. The only downside is their size. I don't think that's a big deal for improved sound quality.

The best thing to do, is to get your film cap (2.2-3.3uf), solder the 22k resistor and cap together. They both have long leads on them, so just wrap the resistor lead around the cap lead and solder 'em together. Place the cap/res where you want it in the amp case. The closer to the amp itself, the better. Secure it with tape or glue so it doesn't move around and pull on the thin wire. At this point, you should solder the thin wire to your film cap and then solder the other end to the pad on the board. Do the same for the resistor end and run that to your input connector or appropriate potentiometer tab. Repeat the process for the other channel.

This guy uses Black Gate capacitors in his diagram, but really, film caps are much better than even Black Gates. Even cheap Solen caps from Parts Express are as good or better. The only downside is their size. I don't think that's a big deal for improved sound quality.