kyndig2

New Head-Fier

- Joined

- Feb 24, 2007

- Posts

- 26

- Likes

- 0

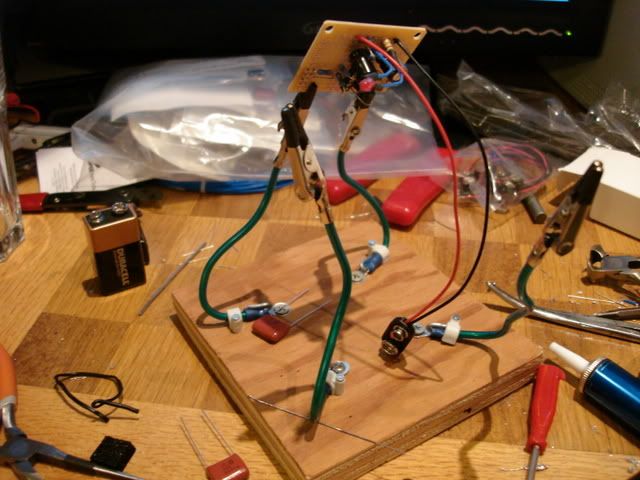

Ok, I was bitten by the DIY amp bug a few weeks ago... I immediately specced out a CMoy amp and had it assembled and working properly within a weekend. During this process I ran into a number of problems and annoyances that I'm sure everyone on here is quite familiar with!

For simplicity sake I will just pour out my questions/problems/whining as a list:

I'm starting to plan out building a Pimeta for my next project... There are just many things that I would like to figure out before I go and spend a bunch *more* money. Ya'll aren't kidding on this hobby getting expensive fast!

For simplicity sake I will just pour out my questions/problems/whining as a list:

- I have had a lot of problems trying to hold things like wires to panel components while attempting to solder them. I have the "Helping Hands" from Ratshack and it helps, but I'm thinking that there must be some other tools that folks use to hold a couple of things in place so that they can make a clean solder join.

- What are some good ways to attach a circuit board to the inside of an enclosure? I have a Serpac H65-9v case that I want to put my CMoy in but haven't figured out a way to immobilize it. I would prefer to not have to make it a completely permanent attachment just in case I decide to replace some of the caps or something.

- I'm looking at buying a small Drill press to do case work, but have never worked with one before. What basic bits and such should I definitely look at getting to take advantage of the press effectively? Also does anyone have suggestions on any good, cheap ones?

- Are there any good explanations of how amplifiers actually work floating around? I've been studying some basic electronics to try to get the basic knowledge, but I only sort of understand how the CMoy that I made works! I've been lurking for a few weeks just reading what others have done to get a better idea. It would just be nice to actually find a solid explanation of why these amps are being made as they are.

- Are there any compiles lists of small additional circuits that can be included in an amp? I'm looking for things like supporting multiple inputs, battery charging circuits, etc. I've seen information on Crossfeeds and bass boost, but most just mention of the addition of other features.

- Does anyone know of some good tutorials on basic electronics. I've been going from the NEETS website from the Navy that I found a link to from Tangentsoft. Its extremely dry and not very well thought out for a web site.

- (added) What are some decent ways to store the various small pieces and parts such as resistors, caps, diodes, etc? I'm really not happy with the small plastic drawers thing I have from Wal-Mart for holding this stuff!

I'm starting to plan out building a Pimeta for my next project... There are just many things that I would like to figure out before I go and spend a bunch *more* money. Ya'll aren't kidding on this hobby getting expensive fast!