ericj

Headphoneus Supremus

- Joined

- Aug 2, 2005

- Posts

- 8,270

- Likes

- 170

In my continuing effort to be a cheap person, here's how i made my own K-501's!

I started out with a pair of K-301's i got off the 'bay for about $16, and some varimotion drivers i found on the 'bay for about $21.

All it takes is some dremel work! And the willingness to ruin a dremel grinding bit.

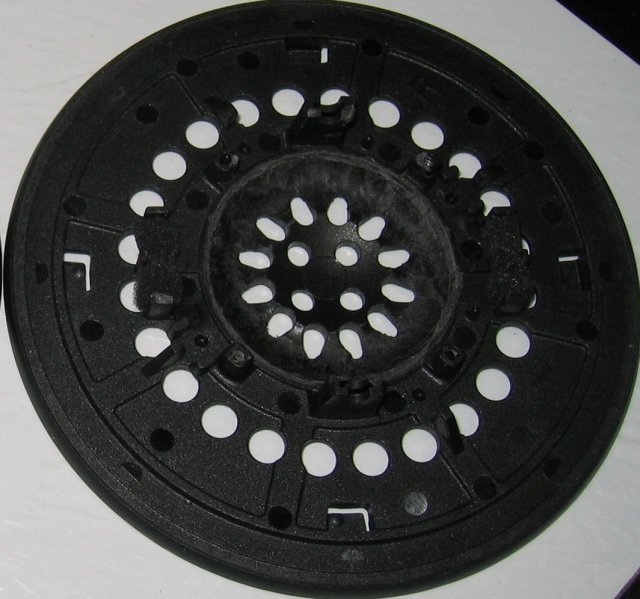

The original K-300/301 baffle disc looks like this:

It appears that the mold for this baffle is a modification of an earlier design that used 42mm drivers like the K-501, with an additional inner ring added to fit snugly around the 38mm K-301 driver.

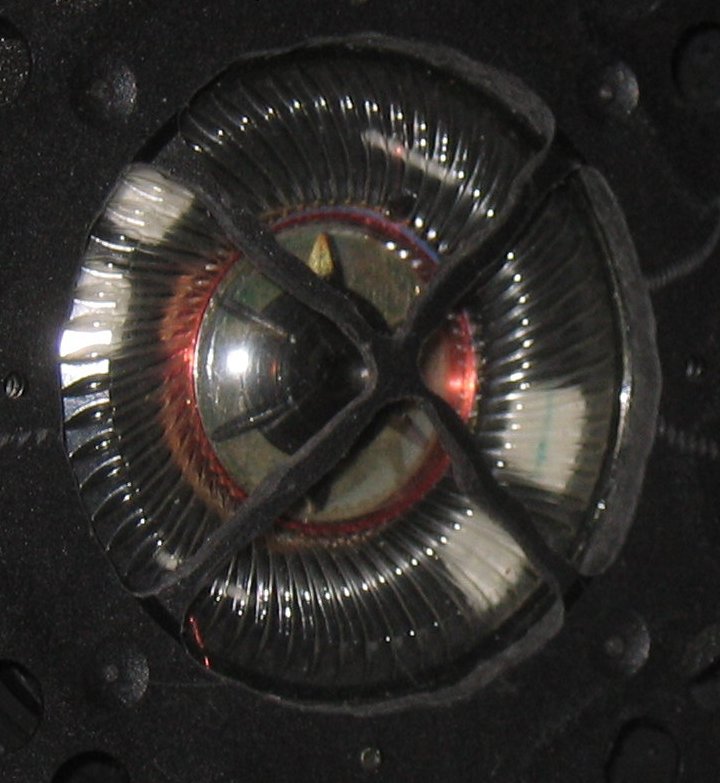

So i got out the dremel and turned it into this:

Fits perfectly!

Sounds pretty good too. There is some harshness in the high end that I'm hoping can be remedied by carving up the baffle some more to let the driver breathe as well as it does in the real K-501 baffle disc.

I considered ordering genuine K-501 baffles from AKG, but if the cardan configuration is different, then I'll have spent $20+ on worthless parts. Plus I'm a cheap person, and i have half a dozen K-30x baffle discs.

I also need to see about damping or sealing some or all of the ports in the baffle. Since there's so much crap sticking out of the disc on the back side, I'll probably have to work from the front. I have some nonwoven fabric here (the stuff they line the bottoms of couches with), I'll cut a few donuts out of it and try gluing them on.

Edit: The technical name of the nonwoven fabric in question is "cambric". It's about twice as hefty and air-blocking as the stuff in my DT-880 Studio's, and about half as hefty and air-blocking as the stuff in my K-141 M's. But yeah, it's the stuff on the bottom of your couch.

I started out with a pair of K-301's i got off the 'bay for about $16, and some varimotion drivers i found on the 'bay for about $21.

All it takes is some dremel work! And the willingness to ruin a dremel grinding bit.

The original K-300/301 baffle disc looks like this:

It appears that the mold for this baffle is a modification of an earlier design that used 42mm drivers like the K-501, with an additional inner ring added to fit snugly around the 38mm K-301 driver.

So i got out the dremel and turned it into this:

Fits perfectly!

Sounds pretty good too. There is some harshness in the high end that I'm hoping can be remedied by carving up the baffle some more to let the driver breathe as well as it does in the real K-501 baffle disc.

I considered ordering genuine K-501 baffles from AKG, but if the cardan configuration is different, then I'll have spent $20+ on worthless parts. Plus I'm a cheap person, and i have half a dozen K-30x baffle discs.

I also need to see about damping or sealing some or all of the ports in the baffle. Since there's so much crap sticking out of the disc on the back side, I'll probably have to work from the front. I have some nonwoven fabric here (the stuff they line the bottoms of couches with), I'll cut a few donuts out of it and try gluing them on.

Edit: The technical name of the nonwoven fabric in question is "cambric". It's about twice as hefty and air-blocking as the stuff in my DT-880 Studio's, and about half as hefty and air-blocking as the stuff in my K-141 M's. But yeah, it's the stuff on the bottom of your couch.