uzziah

Headphoneus Supremus

- Joined

- Oct 15, 2004

- Posts

- 4,049

- Likes

- 14

ok. option with psu is back in

btw: i'm constantly updating the first post. please keep looking there to see what are current issues are to settle.

here they are:

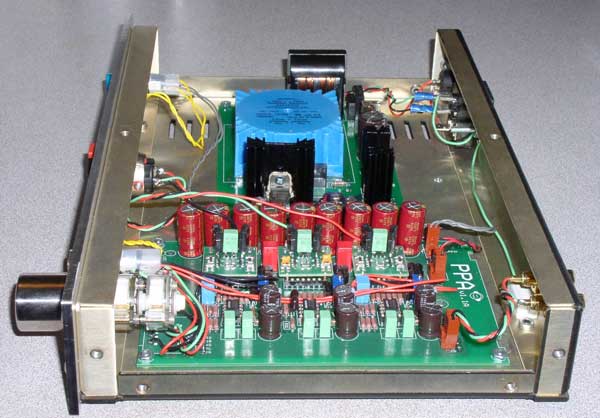

1. slits on top or not? if so, exactly where? (i.e. how far from side?)

2. height of case? it seems that we'll have the same height on option A and option B. should we go with standard 2" or up it to 2.25, 2.5, or 3"??

3. color(s): what is most preferable? annodizing has been strongly reccommended on account of poor paint job results from par-metal.

folks: basically those three questions is IT, and then i can start accepting $ and ordering. let's try to hammer this out quick so we can get this order going.

btw: i'm constantly updating the first post. please keep looking there to see what are current issues are to settle.

here they are:

1. slits on top or not? if so, exactly where? (i.e. how far from side?)

2. height of case? it seems that we'll have the same height on option A and option B. should we go with standard 2" or up it to 2.25, 2.5, or 3"??

3. color(s): what is most preferable? annodizing has been strongly reccommended on account of poor paint job results from par-metal.

folks: basically those three questions is IT, and then i can start accepting $ and ordering. let's try to hammer this out quick so we can get this order going.