ezkcdude

1000+ Head-Fier

- Joined

- Mar 29, 2006

- Posts

- 1,000

- Likes

- 20

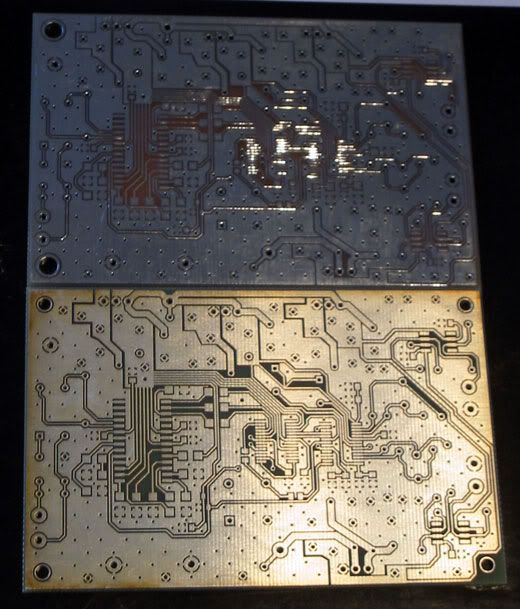

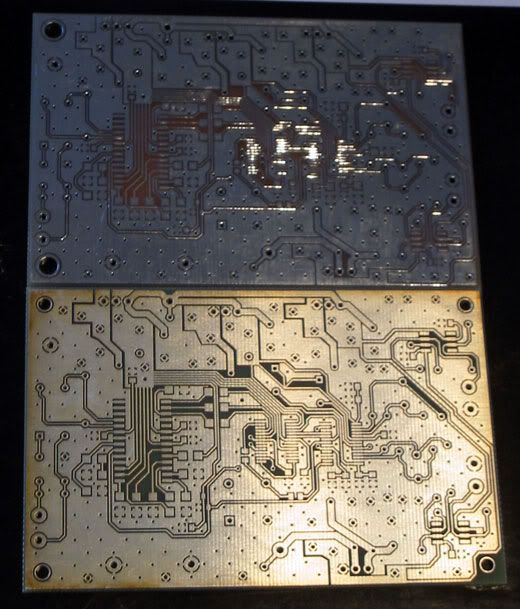

I recently placed an order with ExpressPCB for their mini-board service, which I've done many times. Well, I got the boards on Friday, and lo and behold there something fishy with them. The metal surfaces look much shinier than normal. Compare the new boards (top) with an old board (bottom). Does anyone have an idea what is going on? Unfortunately, it appears you can only contact ExpressPCB by e-mail, not phone. I'm not sure what to do.