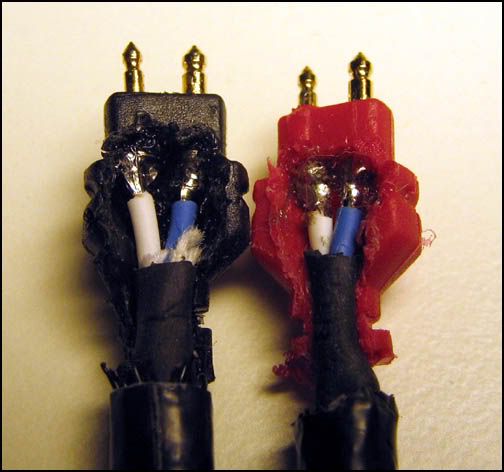

I'd first take a soft-bristled toothbrush and some rubbing alcohol and clean out the connector shell and wire insulation of debris, oil from fingers on them, etc for best bond.

I doubt hot-glue is going to be sturdy enough, epoxy would do better.

Unless you're in a real rush, slow-set epoxy works best, IMO, in addition to being stronger. With the slow-set epoxy you have more time to pour it in, work out any air pockets, pop bubbles that rise to the surface, and have it settle to a nice flat surface. Remember than "5 minute" epoxy isn't workable for the whole 5 minutes, some isn't even very workable for 1 minute after mixing and that's cutting it close.

As for types, there are several... personally I'd buy some you think you can use for several projects. Clear epoxy looks better in some uses but probably not on that, and tends to have lower strength. Good ole JDWeld would probably do fine.