linuxworks

Member of the Trade: Sercona Audio

- Joined

- Oct 10, 2008

- Posts

- 3,456

- Likes

- 70

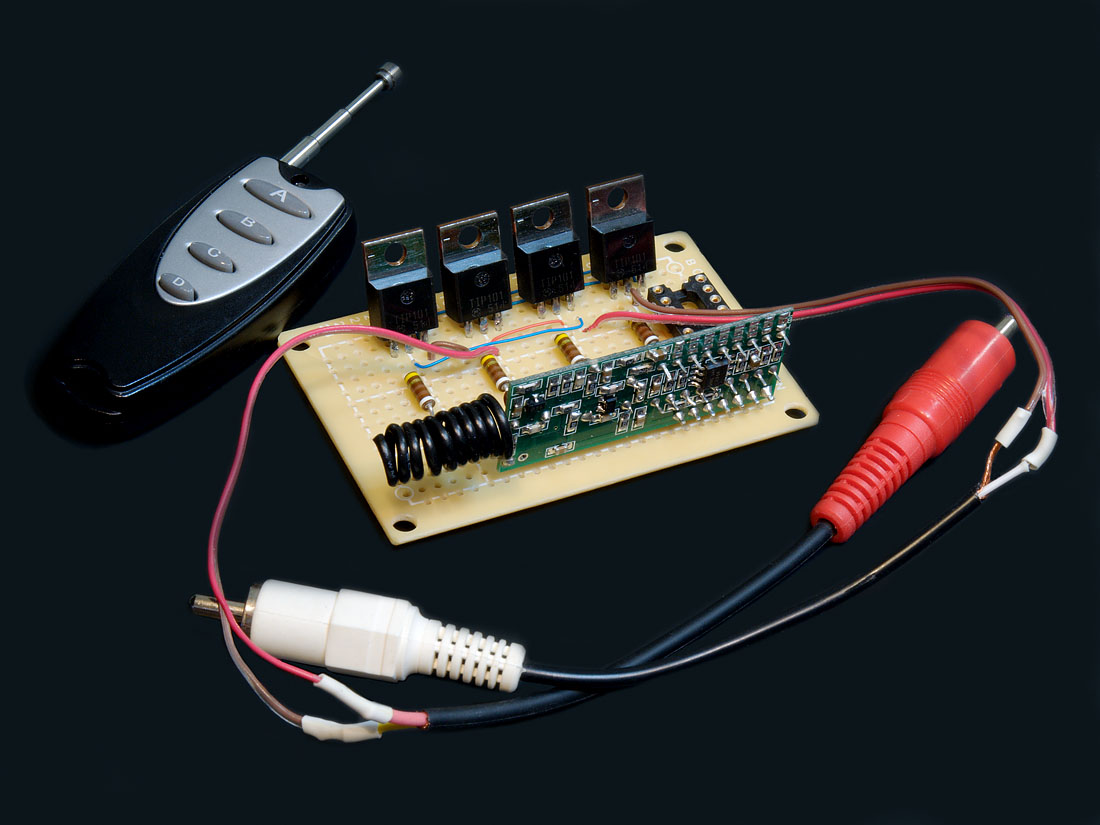

I have some more motorized pots coming on order and I thought I'd ask what people are using to control them.

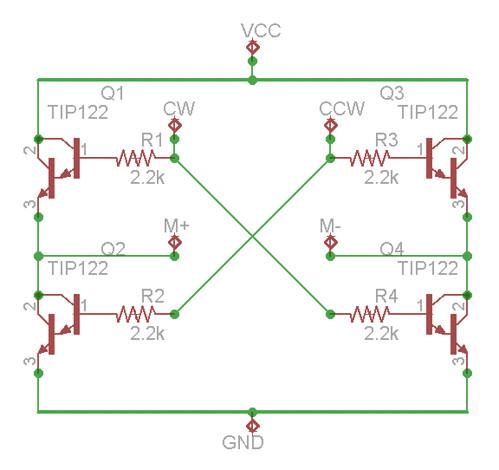

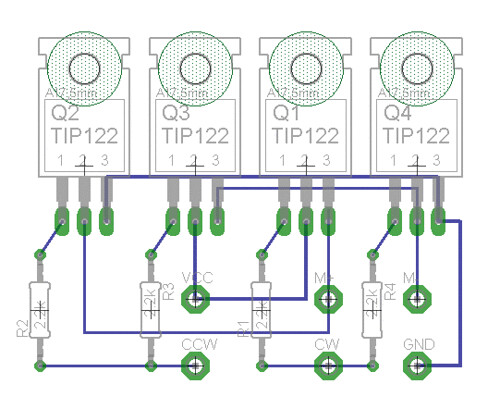

my first version uses 'simple and dumb' relays. these are dc motors and you either run 12v in one polarity to get one rotation and reverse the leads to get the motor to spin the other way. its super simple but I'd like to remove the relay and do it all silently (transistors maybe).

currently, I use 2 DPDT relays and you activate one relay to get one spin direction or the other for the other. all the relays do is map the 2 poles +/- to NC pins that are straight or swapped (from relay 1 or 2). its that simple and it works fine. but there's this annoying click everytime I remotely control these and I want to get rid of that

also, my control inputs are going to be pushbutton modeled as you'd expect: press and hold to move the motor and release the button (the up or down button) to stop the motion. no latching in this circuit, just momentary presses mapped to pos or neg polarity volts to the motor.

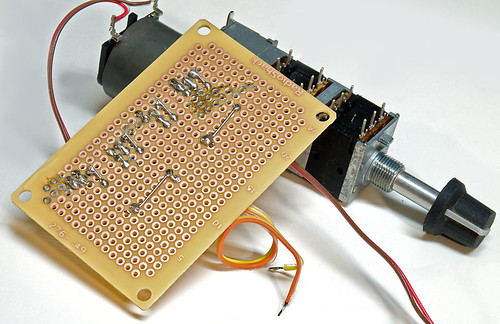

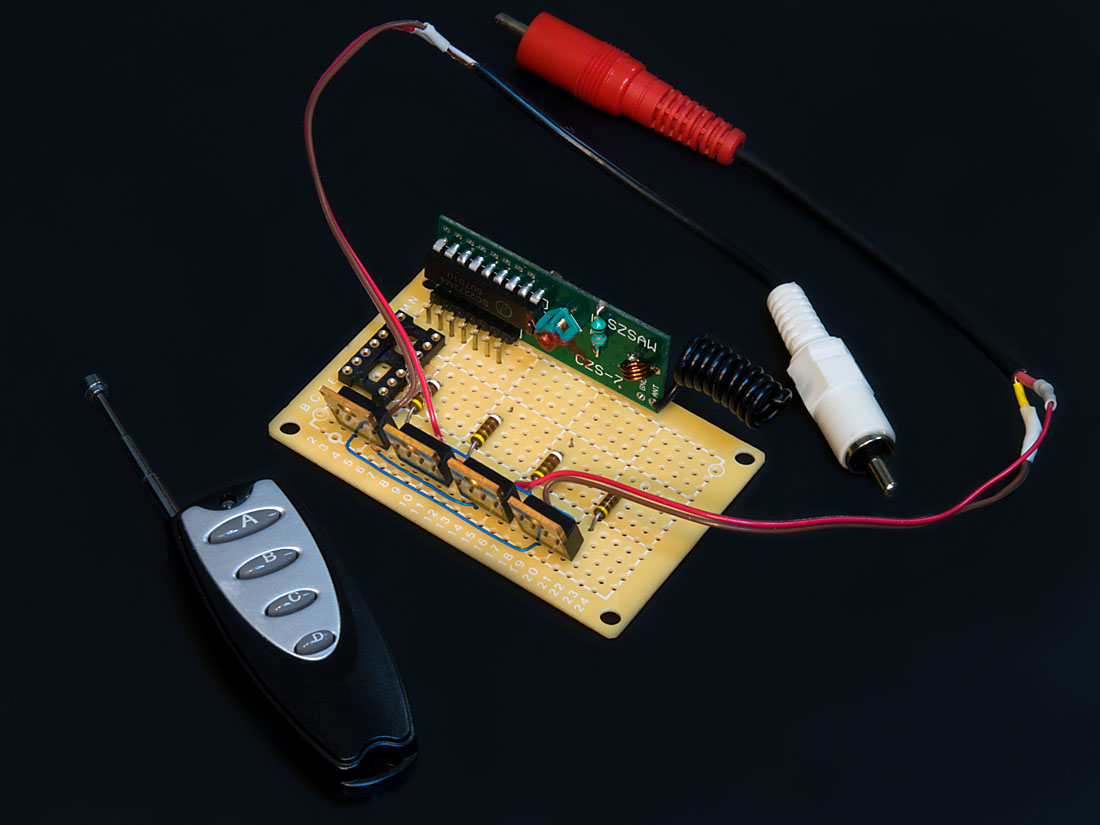

btw, here's an early view of my first version:

this was before I had the relays or the IR receiver connected. the motor pot is there just begging to be connected

anyone have an already-worked-out solution that doesn't use relays for motor reversing?

my first version uses 'simple and dumb' relays. these are dc motors and you either run 12v in one polarity to get one rotation and reverse the leads to get the motor to spin the other way. its super simple but I'd like to remove the relay and do it all silently (transistors maybe).

currently, I use 2 DPDT relays and you activate one relay to get one spin direction or the other for the other. all the relays do is map the 2 poles +/- to NC pins that are straight or swapped (from relay 1 or 2). its that simple and it works fine. but there's this annoying click everytime I remotely control these and I want to get rid of that

also, my control inputs are going to be pushbutton modeled as you'd expect: press and hold to move the motor and release the button (the up or down button) to stop the motion. no latching in this circuit, just momentary presses mapped to pos or neg polarity volts to the motor.

btw, here's an early view of my first version:

this was before I had the relays or the IR receiver connected. the motor pot is there just begging to be connected

anyone have an already-worked-out solution that doesn't use relays for motor reversing?