- Joined

- Nov 26, 2002

- Posts

- 2,994

- Likes

- 1,492

Edit 9/24: new simulation results

For some obscure reason, every time a newborn surfaces at home, I somehow get into the mood to use the software from my work to model the acoustic performance of headphones

I did a quick search for that kind of stuff here on HF but didn't find much so I thought it'd be nice to have a thread to discuss assumptions and results... In particular, one of the main issues is guessing of the properties for the transducer so any advice / experience one might have with headphones testing or diy mod would be welcome to refine the models... I have been getting some nice data from member Purrin as well as Tyll Hertsens over at InnerFidelity.com, it really helps with getting some confidence in the models...

Since my wife and I don't make babies that often, I have really just made models for two headphones so far

With the second baby born last week, I ventured into the modeling of Stax's SR009, and I have some preliminary results to share here. For the people familiar with modeling of vibro-acoustics, the current model was using coupled structural and acoustic Finite Elements. The exterior domain is severely truncated but acoustic boundary conditions are applied to simulate radiation into free field.

As a reference, here is a measurement of the SR-009 acoustic performance performed on dummy head by Tyll at Inner Fidelity. DISCLAIMER: these graphs were generated by me with my own post-processing routines. Although I try to pay attention, mistakes in the code / misunderstandings in the raw data may have occurred, trust with caution

... Note also that these results are equalized (correction for the dummy head influence), but not averaged for different earcup positions so interpret with care (go to InnerFidelity website for equalized / averaged and other results).

... Note also that these results are equalized (correction for the dummy head influence), but not averaged for different earcup positions so interpret with care (go to InnerFidelity website for equalized / averaged and other results). What got me curious is the source of resonances around 2-4kHz, illustrated here through Cumulative Spectral Decay Results (see Marv's fantastic work here for more info on this type results: http://www.head-fi.org/t/566929/headphone-csd-waterfall-plots ):

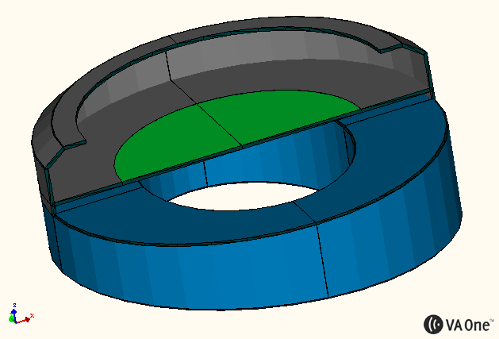

Now on to the SR009 (highly simplified) model. First the geometry, note that the earpads are currently modeled as rigid surfaces. Since there's a thick leather cover, it shouldn't that far off (little absorption):

Here is the resulting SPL at some locations ~1cm above the "ear surface" (currently assumed to be a rigid surface, I may be able to add actual dummy head geometry later on). The microphones at above 1cm apart so you can see typical variations as the headphone is moved around:

Then, some illustration of the pressure response around the headphone and vibration of the membrane at the 3.5kHz (acoustic resonance in the earcup cavity) and 6kHz (lobes in the SPL response at the mic locations):

Finally, an animation of coupled structural/acoustic dynamics at the same 2 frequencies. Note that the diaphragm material is bogus as I have absolutely no idea of the tensioning and resulting natural frequencies. I just used a 1.5 micro meter nylon with increased stiffness to simulate the tension and adjusted that to get the first diaphragm "piston" mode at about 50Hz. This turns into over a thousand wiggling modes in the diaphragm by 10kHz... BTW, the diaphragm is modeled as a circular membrane with "pinned" boundary conditions, which should be fairly realistic. Also, note that these animations are NOT to scale, they just illustrate the vibration and pressure radiation pattern:

More later... Any advice, comments or questions welcome!

Cheers, arnaud