Quote:

Originally Posted by wualta /img/forum/go_quote.gif

Couldn't he simply break off the existing plastic strips? I've always wondered if they were really necessary. Then what you'd have left is.. well, a leather strap. It would flop down and be less easy to put on, but as it is, most of the load is borne by the plastic strips and the leather's just there for looks. At least that's how it looks to me. Any thoughts?

|

True, it would just be a floppy leather-like strap. Like i have on my oldschool DT990 and DT880-S.

The tricky part then would be removing the plastic without tearing the, well, whatever it is. I mean it might be leather, but i doubt it.

That i haven't tried.

I did try crimping a fold of thin aluminum sheet over the crack in my YH-2 headband, and that basically worked, but was always catching my hair.

You could do the same with thin polycarbonate (read as: cuttings from a retail blisterpack) backed with uberdoubletape, maybe, but that might still catch hairs pretty easily.

As far as i know, there's no non-laminar way of fixing them. At least not that i can think of. Not long term anyway.

Quote:

Originally Posted by wualta

[thinks] Hmm.. I wonder if a silk tie is dense enough...

|

Funny you should mention that.

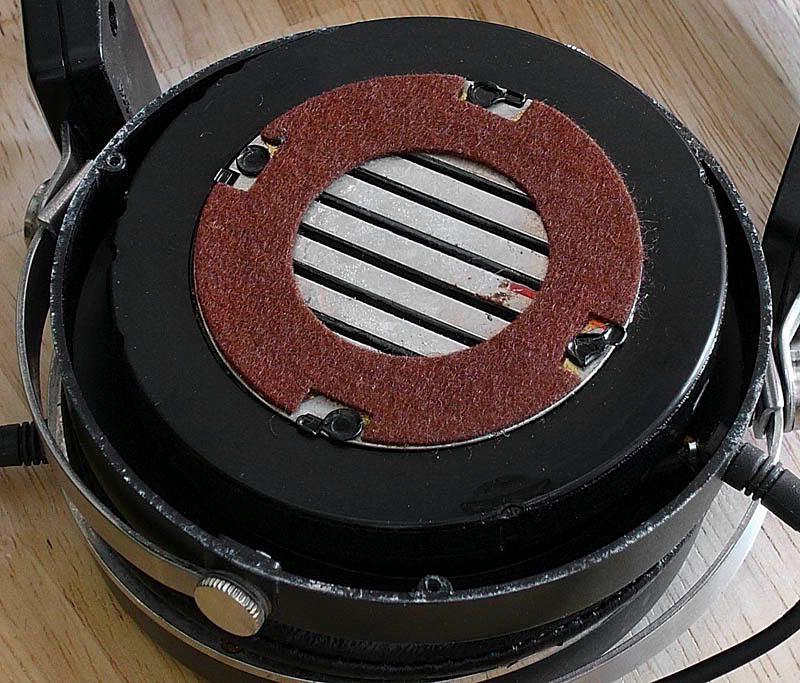

I was repotting my working YH-2 into a UR40 today (or rather, the UR40's non-folding radioshack brother) and for some reason decided to touch up the YH-2 baffles while i was at it.

These were the baffles that i soaked in alcohol for several hours so i could peel off the 'gasket' and replace the fabric.

The first thing i'd tried there was silk from a tie. It was reasonably transparent but the problem with the stuff in that position is that it can't be tensioned the way grille fabric should be.

Plus I'd used a flexible urethane glue, which wasn't really working out. That was before i bought the uberdoubletape.

Re-did 'em in stretchy nylon. Also cut doubletape for the baffle faces with gaps around the screws.

Why'd I do all this? I have no idea. Maybe when i finally get fed up with the YH-2 design I'll put it all back together and sell them on ebay for a king's ransom.

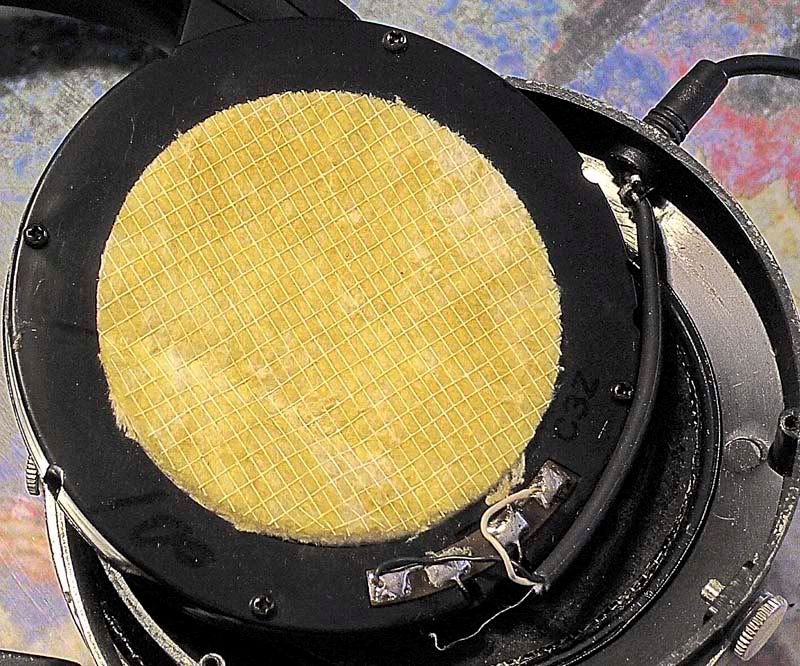

The UR40 fosterfone -- that's with a bluetak gasket between driver and baffle, bluetak over the ring of holes in the baffle, low-density felt over the back of the driver, paper reflex dot in the center of the driver (and now I'm thinking it should have been off-center), fishfoam instead of the original damping foam, and another layer of low-density felt over the back grille.

Oh, and I've peeled all the vinyl off the pads, so they're just terry cloth.

The sound? even, bass is there but a little rolled off.

So now I'm wondering, when i go back in, do i add another layer of felt over the back of the driver, or use higher density felt over the back grille, or what.