Trevor, the op-amp I'm going to try out first for this amp is the OP177GP, which someone had mentioned in a previous thread.

Just to be thorough, I'm going to repost my board propagation quasi-guide in this thread (I had posted it in the Dynahi pics board earlier today)...

On the right in this picture on top and bottom are spaces for resistors -- these can be recognized by the long rectangular shapes with leads coming out each end. Resistor orientation isn't really specific, but for continuity you should orient it so that the letters on the board and resistor are going in the same direction. Pull the leads in from each side of the resistor so that it is close to the board itself.

To the left on top and bottom are transistor slots -- the transistors themselves have three leads that all eventually bend inward. You want to push the leads through until you reach those bends. You should feel resistance when you get there. Orient the transistor so that the curved side lines up with the curved image on the board.

Here we have a transistor slot with a heat sink attached, as shown in the image. Again, line the heat sink (the silver part of this type of transistor) up as it is shown on the board.

Here you can see a slot for a capacitor -- note the + next to one of the holes. This indicates that the capacitor is a polarised one, and the positive lead goes in the plus side. You should be able to identify the positive lead because it should be longer than the negative lead.

Here is an image of the op-amp slot on the board. Again, the indent seen on the left side of the op amp should line up with the indent (or sometimes simply a mark or small hole) on the op-amp. You might want to first install a socket for the op amp so that you can easily replace it if it goes dead or you want to do some op-rolling. ^_^

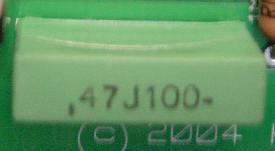

This is a picture of the rectangular capacitor that's near the bottom towards the middle-left of the board. This is a non-polarised capacitor, but you may as well orient it so that the text on the cap sits the same way as the text on the board.