downsize

Member of the Trade

- Joined

- Jan 5, 2010

- Posts

- 898

- Likes

- 14

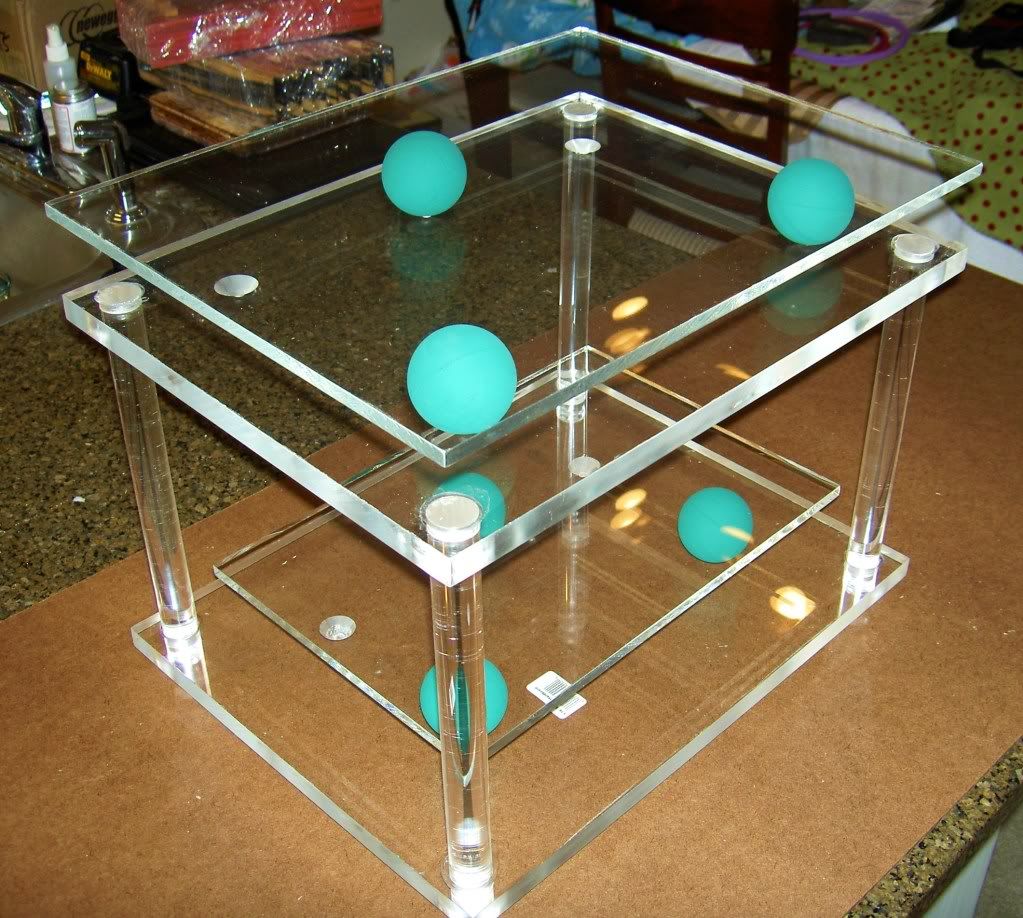

OK ... Maybe some will see this as going to extremes, but I made one of these for my home system to put under my Lexicon RT-20 disc player, and it made an incredible difference in neutrality, soundstage, and dynamics ...

It's not finished yet, but I figured I would go ahead and show the progress thus far.

Acrylic is the single most acoustically inert material suitable for an audio shelf/stand IMO. This is because if you study it under a microscope, you would find it has literally billions of miscroscopic fibers running in all directions. This lowers it's resonant frequency to below our audible hearing threshold. That resonant frequency is approx 10 hz.

Racquetballs are VERY, VERY efficient heat dissipators. PERFECT for my design goal of a resonance free headfi stand.

Here is the technical reasoning behind this :

Viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation. Viscous materials, like honey, resist shear flow and strain linearly with time when a stress is applied. Elastic materials strain instantaneously when stretched and just as quickly return to their original state once the stress is removed. Viscoelastic materials have elements of both of these properties and, as such, exhibit time dependent strain. Whereas elasticity is usually the result of bond stretching along crystallographic planes in an ordered solid, viscosity is the result of the diffusion of atoms or molecules inside an amorphous material.

Unlike purely elastic substances, a viscoelastic substance has an elastic component and a viscous component. The viscosity of a viscoelastic substance gives the substance a strain rate dependent on time. Purely elastic materials do not dissipate energy (heat) when a load is applied, then removed. However, a viscoelastic substance loses energy as heat when a load is applied, then removed. Hysteresis is observed in the stress-strain curve, with the area of the loop being equal to the energy lost during the loading cycle. Since viscosity is the resistance to thermally activated plastic deformation, a viscous material will lose energy through a loading cycle. Plastic deformation results in lost energy, which is uncharacteristic of a purely elastic material's reaction to a loading cycle.

To damp the panels to reduce resonant vibrations, damping must be energy dissipated at the panels. The key feature of a damping material is that they are viscoelastic. Viscoelastic materials require energy to be extended and compressed. This is exactly where we want the vibration energy from the panels to go, into the viscoelastic materials and then dissipated as heat

[size=large]Racquetballs are perfectly viscoelastic [/size]

Amp and power supply goes on bottom shelf, source on top. As I said, it is NOT finished yet, and will look MUCH better when it is. Hope you enjoy this !

PS; Now I just wonder how long it takes before this thread is locked ... LOL

It's not finished yet, but I figured I would go ahead and show the progress thus far.

Acrylic is the single most acoustically inert material suitable for an audio shelf/stand IMO. This is because if you study it under a microscope, you would find it has literally billions of miscroscopic fibers running in all directions. This lowers it's resonant frequency to below our audible hearing threshold. That resonant frequency is approx 10 hz.

Racquetballs are VERY, VERY efficient heat dissipators. PERFECT for my design goal of a resonance free headfi stand.

Here is the technical reasoning behind this :

Viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation. Viscous materials, like honey, resist shear flow and strain linearly with time when a stress is applied. Elastic materials strain instantaneously when stretched and just as quickly return to their original state once the stress is removed. Viscoelastic materials have elements of both of these properties and, as such, exhibit time dependent strain. Whereas elasticity is usually the result of bond stretching along crystallographic planes in an ordered solid, viscosity is the result of the diffusion of atoms or molecules inside an amorphous material.

Unlike purely elastic substances, a viscoelastic substance has an elastic component and a viscous component. The viscosity of a viscoelastic substance gives the substance a strain rate dependent on time. Purely elastic materials do not dissipate energy (heat) when a load is applied, then removed. However, a viscoelastic substance loses energy as heat when a load is applied, then removed. Hysteresis is observed in the stress-strain curve, with the area of the loop being equal to the energy lost during the loading cycle. Since viscosity is the resistance to thermally activated plastic deformation, a viscous material will lose energy through a loading cycle. Plastic deformation results in lost energy, which is uncharacteristic of a purely elastic material's reaction to a loading cycle.

To damp the panels to reduce resonant vibrations, damping must be energy dissipated at the panels. The key feature of a damping material is that they are viscoelastic. Viscoelastic materials require energy to be extended and compressed. This is exactly where we want the vibration energy from the panels to go, into the viscoelastic materials and then dissipated as heat

[size=large]Racquetballs are perfectly viscoelastic [/size]

Amp and power supply goes on bottom shelf, source on top. As I said, it is NOT finished yet, and will look MUCH better when it is. Hope you enjoy this !

PS; Now I just wonder how long it takes before this thread is locked ... LOL