kwkarth

Electronics guys... we have our plusses and minuses. With advent of digital everything, we're being phased out

- Joined

- Sep 30, 2001

- Posts

- 10,307

- Likes

- 100

A little background..

It's been a while since I had mixed a live concert for recording or sound reinforcement and I was asked by a friend a couple weeks ago to do that for a gig where there would be four bands, each with completely different mic requirements and set ups. I had never even met any of the musicians in the four bands except for the pianist who had invited me to help. After having read so many things here about the Ultrasone cans and how good they all were, I decided I had a perfect excuse to buy a pair of Ultrasones to see how they would do as monitoring cans. I set my sights on the Pro-650s because the local Guitar Center had them in stock (and none of the other ProLine series.) and because some of the reviews I had read on the web indicated that many liked the 650s over the 750s.

OK, so I picked up a pair on my lunch hour and took them back to the office to give them a listen because I couldn't wait to hear them until I got home in the evening. I work for myself anyway, so I justified it...

Anyway, long story short, they were a BIG disappointment out of the box. The demo pair sounded good to my ears with their demo material at the store, but I had not listened to them with any material I was familiar with.

Compared to my K701s, both cans being driven by my RSA SR-71, the K701 sounded its usual glorious self, but the 650 had a honky, hollow coloration in the upper mids that drove me batty. I also noticed that they didn't isolate very well at all.

So then I thought I would give them some burn in before the gig and try them anyway for the mix down, then about 4 days away. I put them in my office at home plugged into a little TEAC receiver set to an FM station playing jazz a little louder than I would normally listen. They ran 24/7 for those 4 days. At the end of that burn in, they had improved a little tonally, but of course, the isolation hadn't changed, nor did I expect it to. They were still not near accurate/neutral enough to use to set mix levels for a band, but I brought them to the gig anyway along with my trusted Beyer DT-250-80s and ETY ER-4P/S. About 10 seconds of listening in the live gig was all I needed to determine that they were useless for that purpose. I reverted back to my trusty DT-250s, and completed the job with the Beyers.

Later, back at the ranch...

I was seriously considering selling them, but also curious to know if they could be improved. I was considering opening up the vents on them like the 2500s since it was only a couple pieces of plastic making them "sealed" covering the vents.

I opened up one side of the 650s one morning before I left the house. There was what looked like a black plastic ring glued over the vents that are visible from the outside on the 2500s. Rather than remove that ring, I decided first to try adding some acoustic and vibrational damping material to the inside of the ear cup because it was totally empty in there, stock!

I decided to use a layered approach to tame all audio frequencies. I used a mechanical damping material for the plastic ear cup itself, (Dynamat) and a layered sandwich of heavy wool felt, heavy polyester felt, and a fabric backed poly foam.

If you're at all familiar with the "putty" they use to install automotive windshields, this Dynamat stuff looks and feels like that with a layer of lead foil (but it's not lead) laminated to the gooey sticky stuff. It has a great "thud" factor. (In other words, you can stick even a little bit of this stuff to something that rings like a bell, and after you put that stuff on it, it doesn't ring any more, it just goes "thud" when you thump it.

So, the ear cups were opened up and measured. I cut a 7cm circles of the Dynamat, the wool felt, the Poly felt, and the foam backed fabric. I applied the Dynamat directly to the inside of the ear-cup shells, then layered the fabric backed foam on top of the Dynamat, then the wool felt, then the poly felt. The driver and baffle board were then mounted back into the shells on top of the damping sandwich. See pictures below:

Before the operation:

With the earpad removed.

Next, remove the four screws that hold the baffle board to the shell.

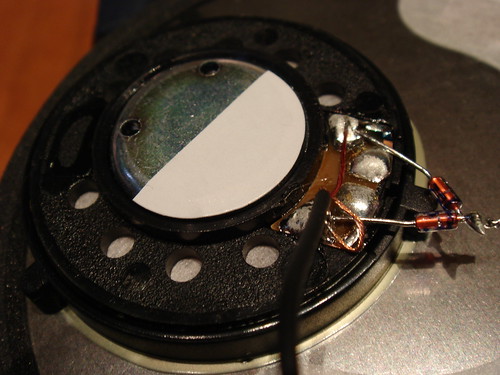

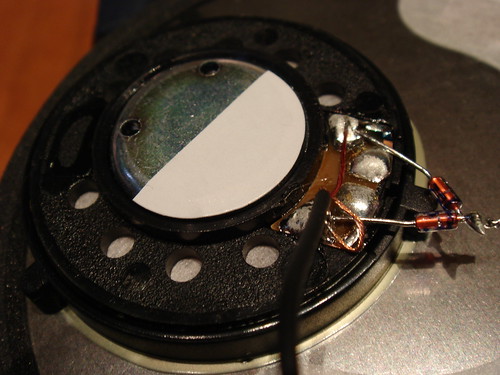

Here's a picture of the back of the driver up close just for grins

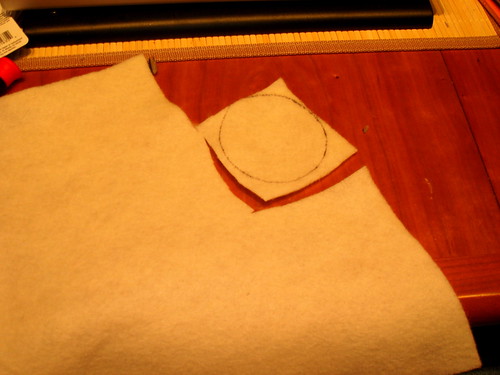

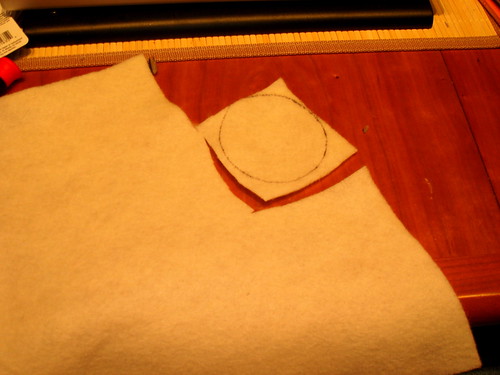

Cutting out a piece of the felt.

Felt, up close and personal:

Here's a picture of the pkg that the Dynamat came in:

The felt and the foam totaled about 10 bux, but the Dynamat, for two lousy pieces, was about $25.

Here's a sheet of the stuff:

Here's the 7cm circle cut out:

Laying it in the cup to check the fit.

Next, make notches in it for the obstructions, peel off the paper backing and adhere it to the ear cup. Press it in reeeel good.

Acoustic damping material, fabric, foam, wool felt, poly felt.

Here's the acoustic sandwich before I layed it in the cup.

I bet you're wondering how they sound??

You wouldn't recognize them. They sound very impressive now! I could do a mixdown with these babies! Much more neutral. Bass extension is better, midrange coloration is gone, highs are sweet and extended with no more stridency.

They isolate the ambient room noise at least 10db better than before.

I'm going to have to live with these for a while to make sure I'm not fooling myself, but man! This worked far better than I ever expected!

Has anyone else tried this mod?

It's been a while since I had mixed a live concert for recording or sound reinforcement and I was asked by a friend a couple weeks ago to do that for a gig where there would be four bands, each with completely different mic requirements and set ups. I had never even met any of the musicians in the four bands except for the pianist who had invited me to help. After having read so many things here about the Ultrasone cans and how good they all were, I decided I had a perfect excuse to buy a pair of Ultrasones to see how they would do as monitoring cans. I set my sights on the Pro-650s because the local Guitar Center had them in stock (and none of the other ProLine series.) and because some of the reviews I had read on the web indicated that many liked the 650s over the 750s.

OK, so I picked up a pair on my lunch hour and took them back to the office to give them a listen because I couldn't wait to hear them until I got home in the evening. I work for myself anyway, so I justified it...

Anyway, long story short, they were a BIG disappointment out of the box. The demo pair sounded good to my ears with their demo material at the store, but I had not listened to them with any material I was familiar with.

Compared to my K701s, both cans being driven by my RSA SR-71, the K701 sounded its usual glorious self, but the 650 had a honky, hollow coloration in the upper mids that drove me batty. I also noticed that they didn't isolate very well at all.

So then I thought I would give them some burn in before the gig and try them anyway for the mix down, then about 4 days away. I put them in my office at home plugged into a little TEAC receiver set to an FM station playing jazz a little louder than I would normally listen. They ran 24/7 for those 4 days. At the end of that burn in, they had improved a little tonally, but of course, the isolation hadn't changed, nor did I expect it to. They were still not near accurate/neutral enough to use to set mix levels for a band, but I brought them to the gig anyway along with my trusted Beyer DT-250-80s and ETY ER-4P/S. About 10 seconds of listening in the live gig was all I needed to determine that they were useless for that purpose. I reverted back to my trusty DT-250s, and completed the job with the Beyers.

Later, back at the ranch...

I was seriously considering selling them, but also curious to know if they could be improved. I was considering opening up the vents on them like the 2500s since it was only a couple pieces of plastic making them "sealed" covering the vents.

I opened up one side of the 650s one morning before I left the house. There was what looked like a black plastic ring glued over the vents that are visible from the outside on the 2500s. Rather than remove that ring, I decided first to try adding some acoustic and vibrational damping material to the inside of the ear cup because it was totally empty in there, stock!

I decided to use a layered approach to tame all audio frequencies. I used a mechanical damping material for the plastic ear cup itself, (Dynamat) and a layered sandwich of heavy wool felt, heavy polyester felt, and a fabric backed poly foam.

If you're at all familiar with the "putty" they use to install automotive windshields, this Dynamat stuff looks and feels like that with a layer of lead foil (but it's not lead) laminated to the gooey sticky stuff. It has a great "thud" factor. (In other words, you can stick even a little bit of this stuff to something that rings like a bell, and after you put that stuff on it, it doesn't ring any more, it just goes "thud" when you thump it.

So, the ear cups were opened up and measured. I cut a 7cm circles of the Dynamat, the wool felt, the Poly felt, and the foam backed fabric. I applied the Dynamat directly to the inside of the ear-cup shells, then layered the fabric backed foam on top of the Dynamat, then the wool felt, then the poly felt. The driver and baffle board were then mounted back into the shells on top of the damping sandwich. See pictures below:

Before the operation:

With the earpad removed.

Next, remove the four screws that hold the baffle board to the shell.

Here's a picture of the back of the driver up close just for grins

Cutting out a piece of the felt.

Felt, up close and personal:

Here's a picture of the pkg that the Dynamat came in:

The felt and the foam totaled about 10 bux, but the Dynamat, for two lousy pieces, was about $25.

Here's a sheet of the stuff:

Here's the 7cm circle cut out:

Laying it in the cup to check the fit.

Next, make notches in it for the obstructions, peel off the paper backing and adhere it to the ear cup. Press it in reeeel good.

Acoustic damping material, fabric, foam, wool felt, poly felt.

Here's the acoustic sandwich before I layed it in the cup.

I bet you're wondering how they sound??

You wouldn't recognize them. They sound very impressive now! I could do a mixdown with these babies! Much more neutral. Bass extension is better, midrange coloration is gone, highs are sweet and extended with no more stridency.

They isolate the ambient room noise at least 10db better than before.

I'm going to have to live with these for a while to make sure I'm not fooling myself, but man! This worked far better than I ever expected!

Has anyone else tried this mod?