JimL11

1000+ Head-Fier

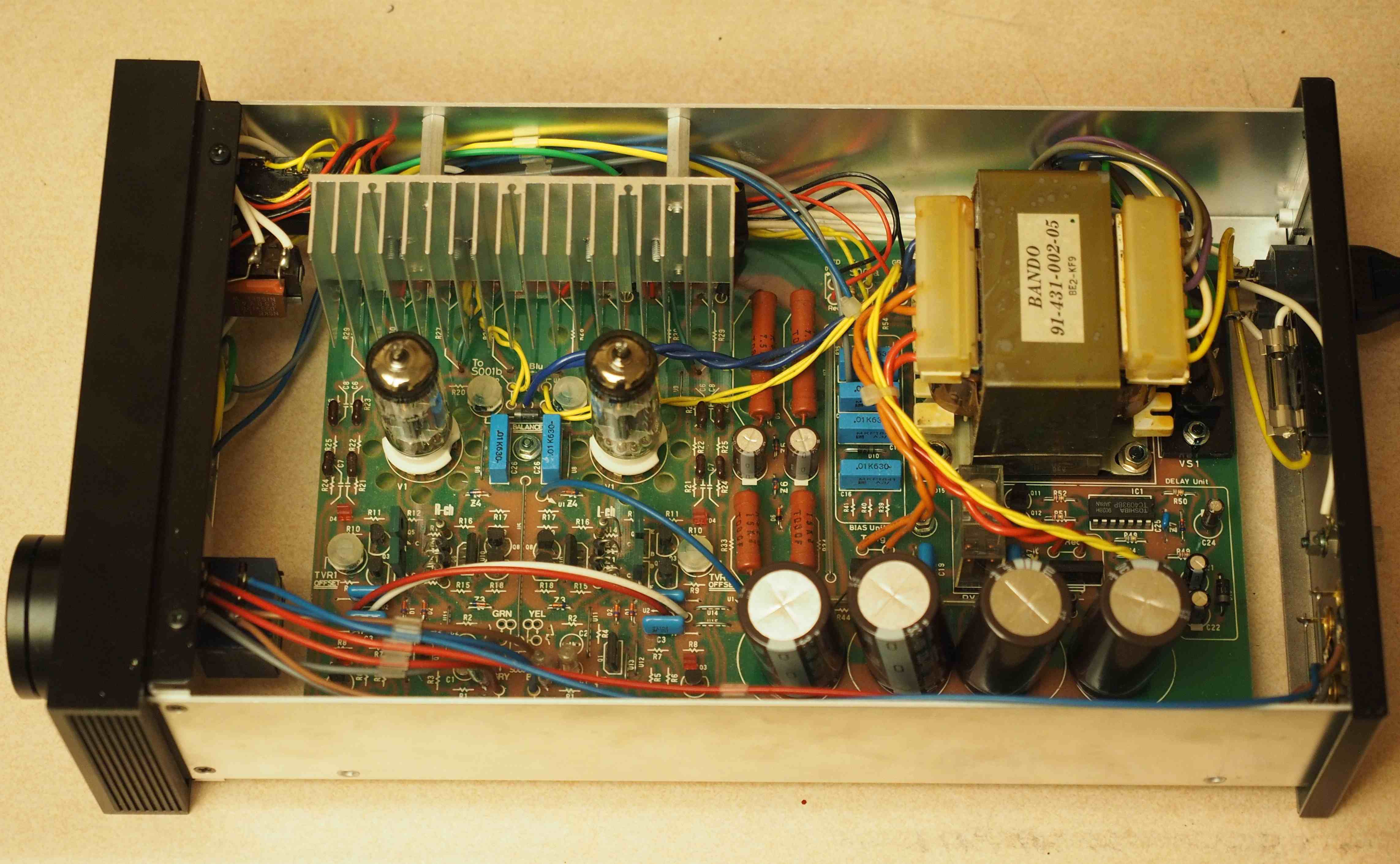

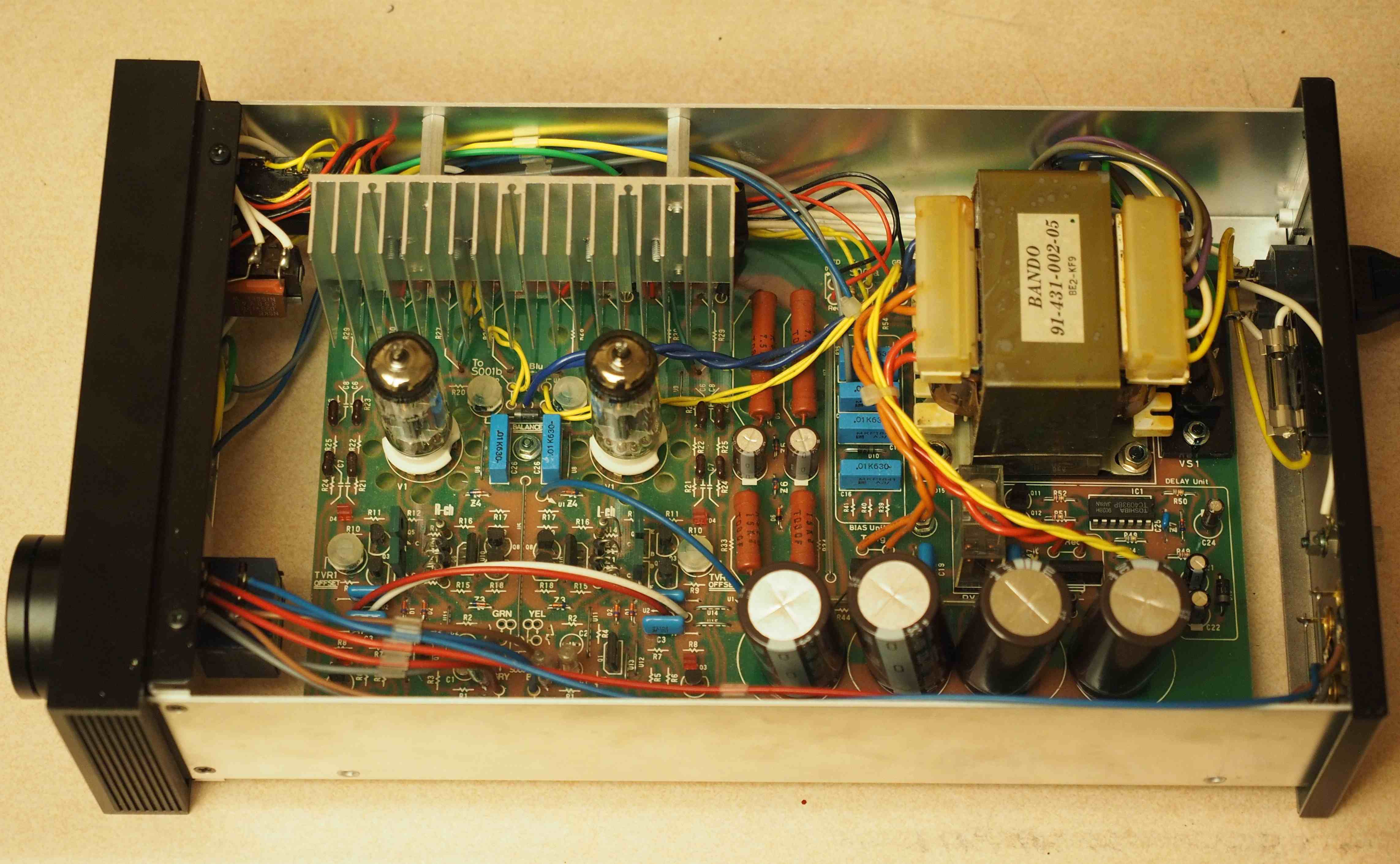

I just published a modification for the Stax SRM-T1/T1S/006 in AudioXpress July 2017, which is out now. The modification adds 5.1 kilohm output safety resistors and cascoded constant current output loads, which with their heatsink fits the space vacated by the plate resistors. It uses the stock 6CG7/6FQ7 output tubes.

Unlike plate resistors, constant current loads burn up practically no signal current, so while the stock amp burns up 9.2 mA signal current in the plate and feedback resistors at its specified 300 VRMS maximum output, the modified amplifier only uses 2.8 mA driving the feedback resistors, leaving much more current available to drive the headphones. Since the output tubes are much less stressed, distortion is decreased and 2 dB of extra headroom gained. This modification can drive even the demanding SR-007, something the stock design strains to do, and improves bass punch, overall clarity and neutrality. Think of it as a T1 on steroids.

The modified circuit is very similar to a KGST. This is no accident, as the KGST was designed to be “a Stax SRM-007t with no cost or retail considerations,” and the 007t is a higher power T1.

The modification lacks the KGST’s regulated power supply, but larger power supply caps have been fitted. Since the amplifier is fully differential pure class A with current sources or loads at every stage, the current draw is pretty constant, minimizing power supply effects.

Replacing all the old electrolytic power supply caps, as outlined earlier in this thread, should also be done as routine maintenance. Parts cost for the modification is about $35, so total parts cost is around $100. With T1 amplifiers going for $400-$700, this is the best bang for the buck, a good starter project for someone wanting to get into electrostatic amp DIY without going to a full build.

Unlike plate resistors, constant current loads burn up practically no signal current, so while the stock amp burns up 9.2 mA signal current in the plate and feedback resistors at its specified 300 VRMS maximum output, the modified amplifier only uses 2.8 mA driving the feedback resistors, leaving much more current available to drive the headphones. Since the output tubes are much less stressed, distortion is decreased and 2 dB of extra headroom gained. This modification can drive even the demanding SR-007, something the stock design strains to do, and improves bass punch, overall clarity and neutrality. Think of it as a T1 on steroids.

The modified circuit is very similar to a KGST. This is no accident, as the KGST was designed to be “a Stax SRM-007t with no cost or retail considerations,” and the 007t is a higher power T1.

The modification lacks the KGST’s regulated power supply, but larger power supply caps have been fitted. Since the amplifier is fully differential pure class A with current sources or loads at every stage, the current draw is pretty constant, minimizing power supply effects.

Replacing all the old electrolytic power supply caps, as outlined earlier in this thread, should also be done as routine maintenance. Parts cost for the modification is about $35, so total parts cost is around $100. With T1 amplifiers going for $400-$700, this is the best bang for the buck, a good starter project for someone wanting to get into electrostatic amp DIY without going to a full build.

Last edited:

)

)