TzeYang

500+ Head-Fier

- Joined

- Mar 19, 2006

- Posts

- 960

- Likes

- 10

In this thread, we post pictures and discuss the fun and wonders of using strips boards, perfboards, and wires point to point.

There are too many people with PCB work these days, it'll be fun and refreshing to see some "real"(hassle) diy work.

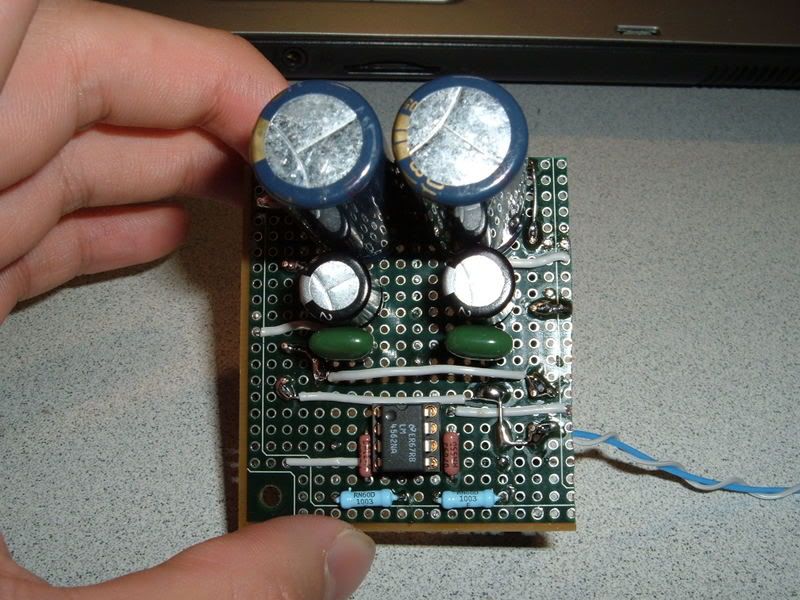

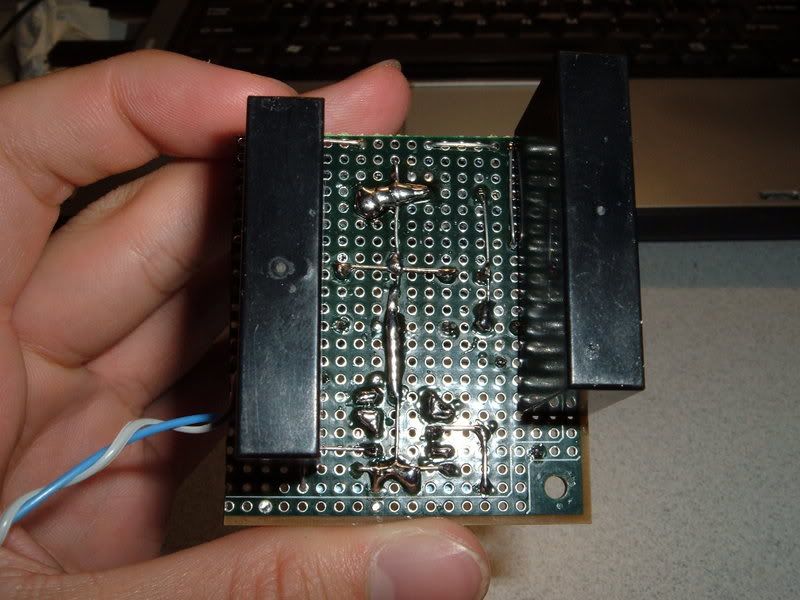

My work, a month ago. An adjustable diamond buffered desktop amp with improved current mirror for biasing.

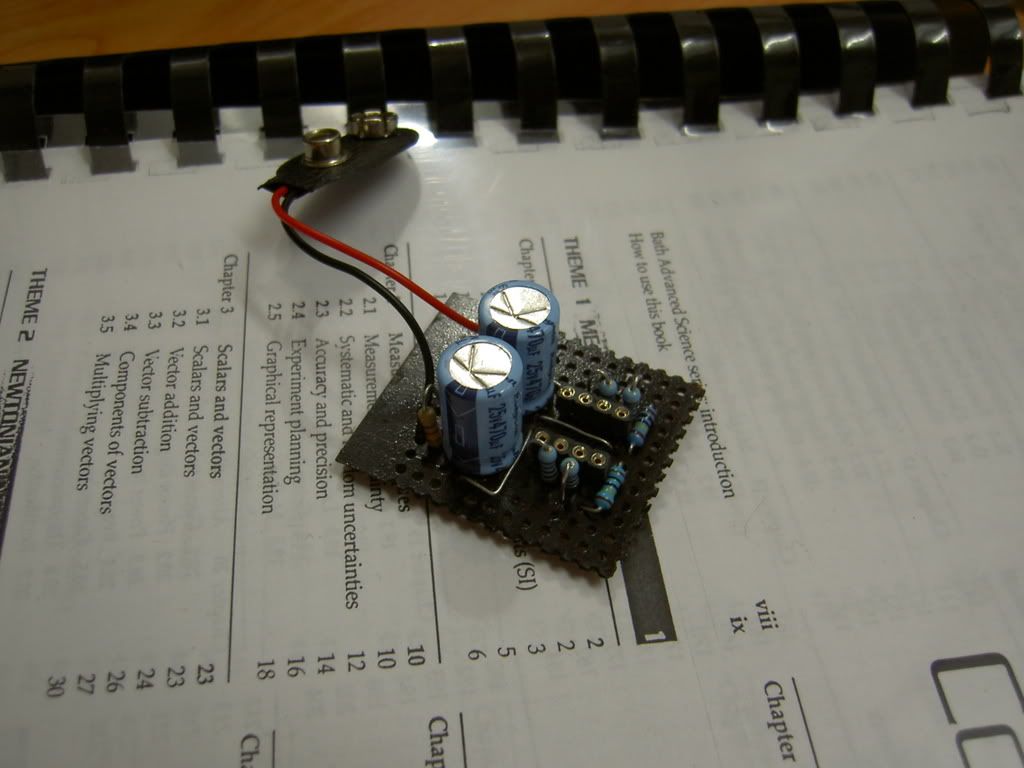

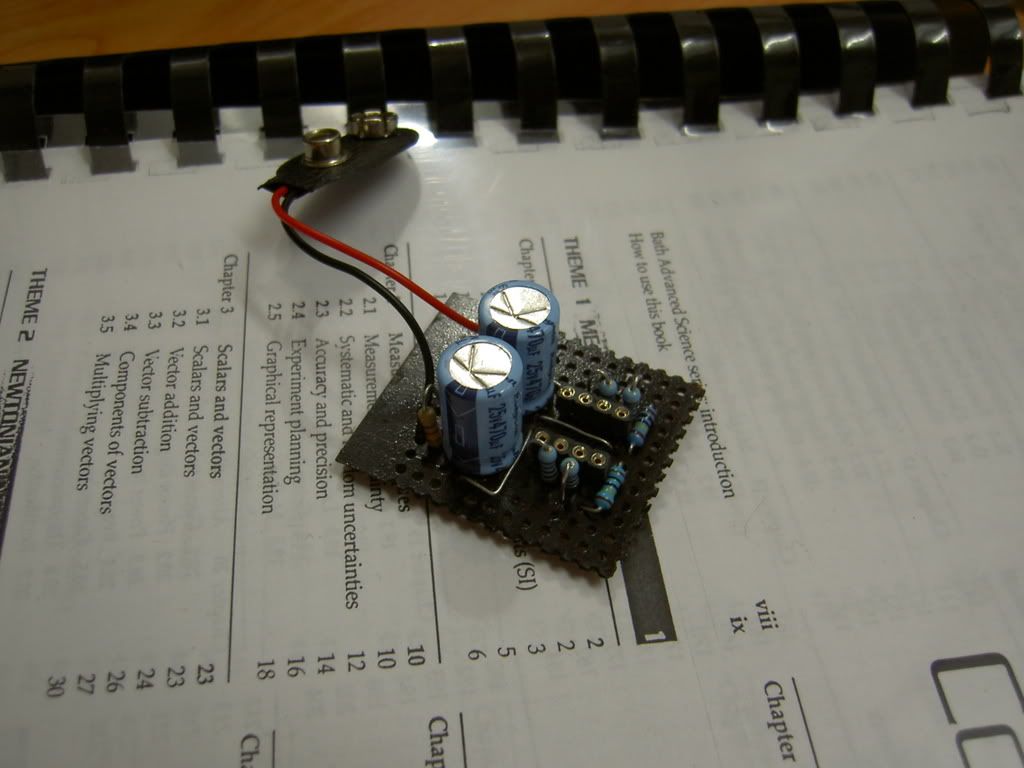

A Cmoy i built half a year ago.

Portable Diamond Buffered Amp.

There are too many people with PCB work these days, it'll be fun and refreshing to see some "real"(hassle) diy work.

My work, a month ago. An adjustable diamond buffered desktop amp with improved current mirror for biasing.

A Cmoy i built half a year ago.

Portable Diamond Buffered Amp.